In recent years, storage shelves have developed towards automation and intelligence, resulting in the emergence of many different types of intelligent automated storage shelves on the market. Among them, the most favored one by enterprises is the four-way shuttle truck shelf. The shelves of four-way shuttle cars can be divided into two categories based on their different loads: pallet type and material box type. There is basically no difference in the structural form and control method between these two different types of four-way shuttle truck shelves, but the main difference lies in the different loading platform methods. Today, Hagrid Intelligent Equipment will mainly talk to you about the HEGERLS material box type four-way shuttle.

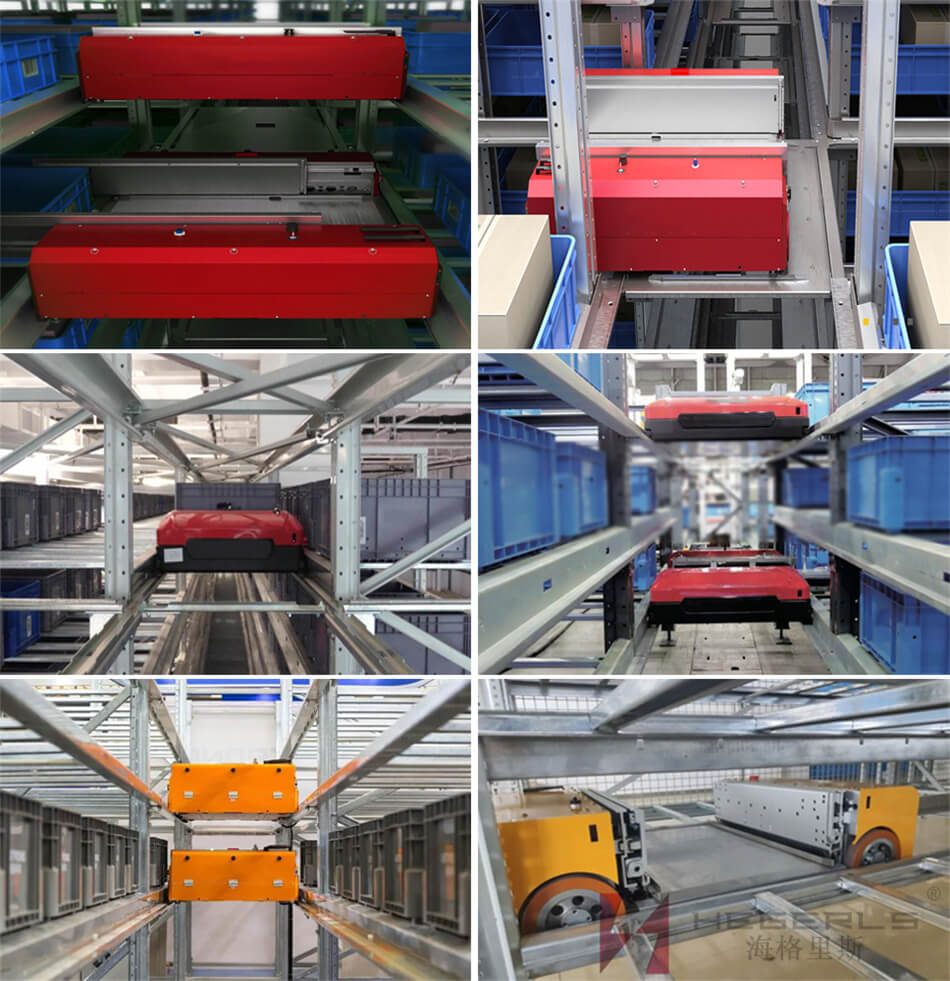

The material box type four-way shuttle is widely used nowadays, on the one hand due to its flexibility and adaptability, and on the other hand, the development of the e-commerce industry has promoted the rapid development of disassembly and sorting. The high efficiency performance of the four-way shuttle is one of the important reasons for its popularity.

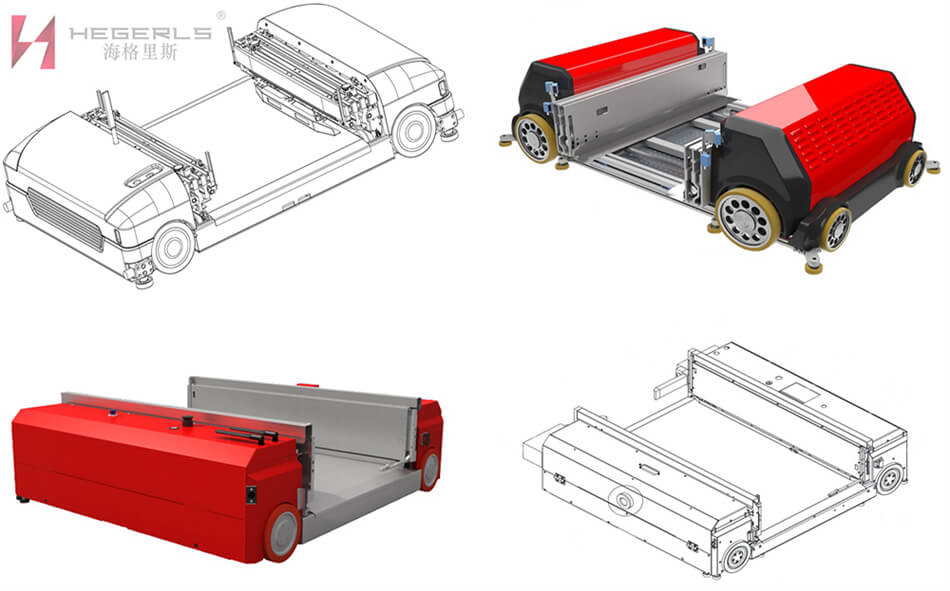

HEGERLS material box type four-way shuttle car

The structural design of the material box type four-way shuttle car is very compact, and compared to the stacking machine three-dimensional warehouse, the floor area is reduced by 30% -50%. It belongs to a high-density storage system and can effectively improve the utilization rate of enterprise warehouse space.

The Hagrid HEGERLS box type four way shuttle is a more flexible product, with corresponding technologies including Miniload and multi-layer shuttle cars. Miniload is an AS/RS system specifically designed for container storage and retrieval. Compared to pallet type AS/RS, Miniload is lighter and faster, but its height is generally not very high, and its load is generally within 50kg. It is similar to a pallet type four-way vehicle in that it has a wide range of adaptability, which can be applied to various warehouse types. At the same time, it can also flexibly increase or decrease the number of carts to match the actual warehouse storage needs, especially in the goods to people picking system. As the carts can be operated by lifting machines to change layers, they can run flexibly in three-dimensional space.

When many enterprises choose storage equipment, the most important focus is on load transfer, speed, and acceleration, and the Hagrid HEGERLS box type four-way shuttle clearly has specific advantages in these three aspects.

In terms of load transfer, the Hagrid HEGERLS four-way shuttle needs to be much more flexible. This is mainly because after the unit becomes smaller and lighter, there are multiple ways to move the load. The simplest way is to use a cargo fork, which is the most important component of the shuttle car. In order to improve storage density, double depth forks can also be used in the Hagrid HEGERLS four-way shuttle products. Sometimes, forks can also be changed in width to accommodate different widths of cardboard boxes.

Speed and acceleration are actually designed to improve work efficiency. The speed of the car can reach up to 5m/s. When using a clamping device, the acceleration of the car can reach 2m/s2, greatly improving the work efficiency of the car. For a hoist, the lifting speed is generally above 4m/s to match the efficiency of the entire system.

In addition to these three aspects, the Hagrid HEGERLS material box type four-way shuttle also has significant characteristics in other aspects. In terms of the system, the Hagrid HEGERLS material box type four-way shuttle belongs to a modular design, with high flexibility, strong expandability, fewer tunnels, and occupying less warehouse area. It has low requirements for warehouse conditions and can be implemented quickly; In terms of solving pain points, there are many SKUs in storage application scenarios and management difficulties; The problems of shallow inventory, low space utilization, and low picking efficiency; In terms of application scenarios, it is suitable for goods to person picking, split picking, and multi category small item picking; It is also widely applicable in various industries such as cold chain, new energy, automotive parts, retail, clothing, 3C, etc.

Post time: Sep-01-2023