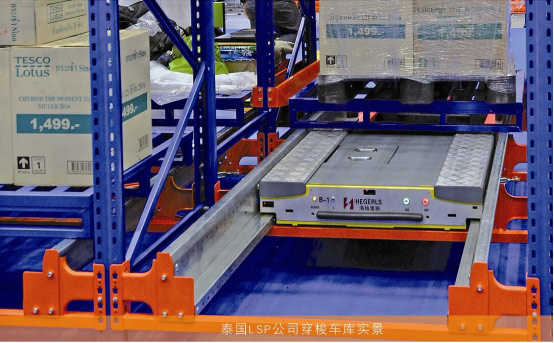

Semi Automatic Storage Warehouse Radio Shuttle Pallet runner car with remote

We provide Radio shuttle runner 2021 high quality ambient and cold room with 1 years quality warranty. We devote ourselves to warehouse storage field for 25 years experience. We are expecting become your long term partner in China.

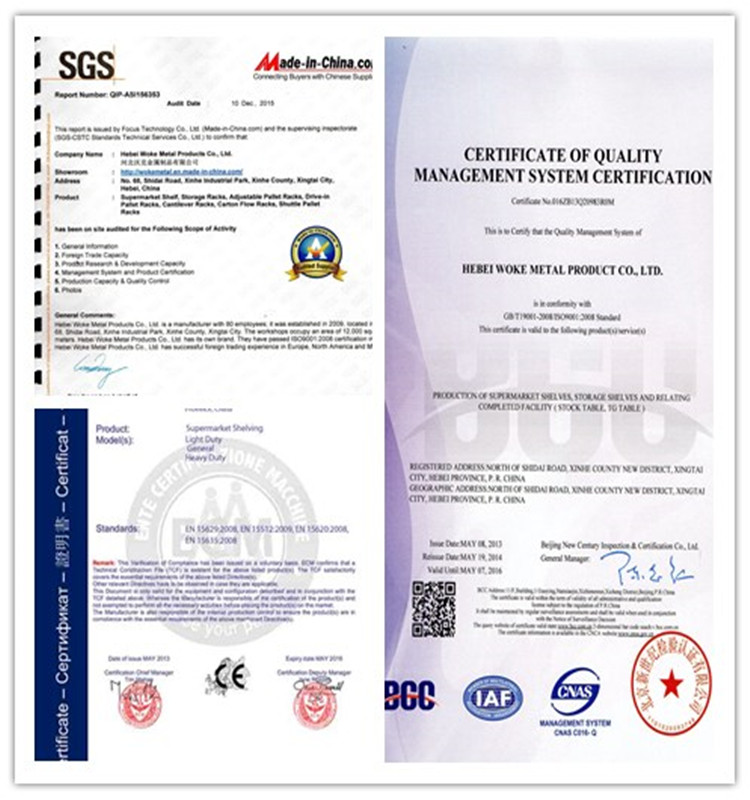

Radio shuttle runner 2021 high quality ambient and cold room with certificate of SGS.BV and TUV

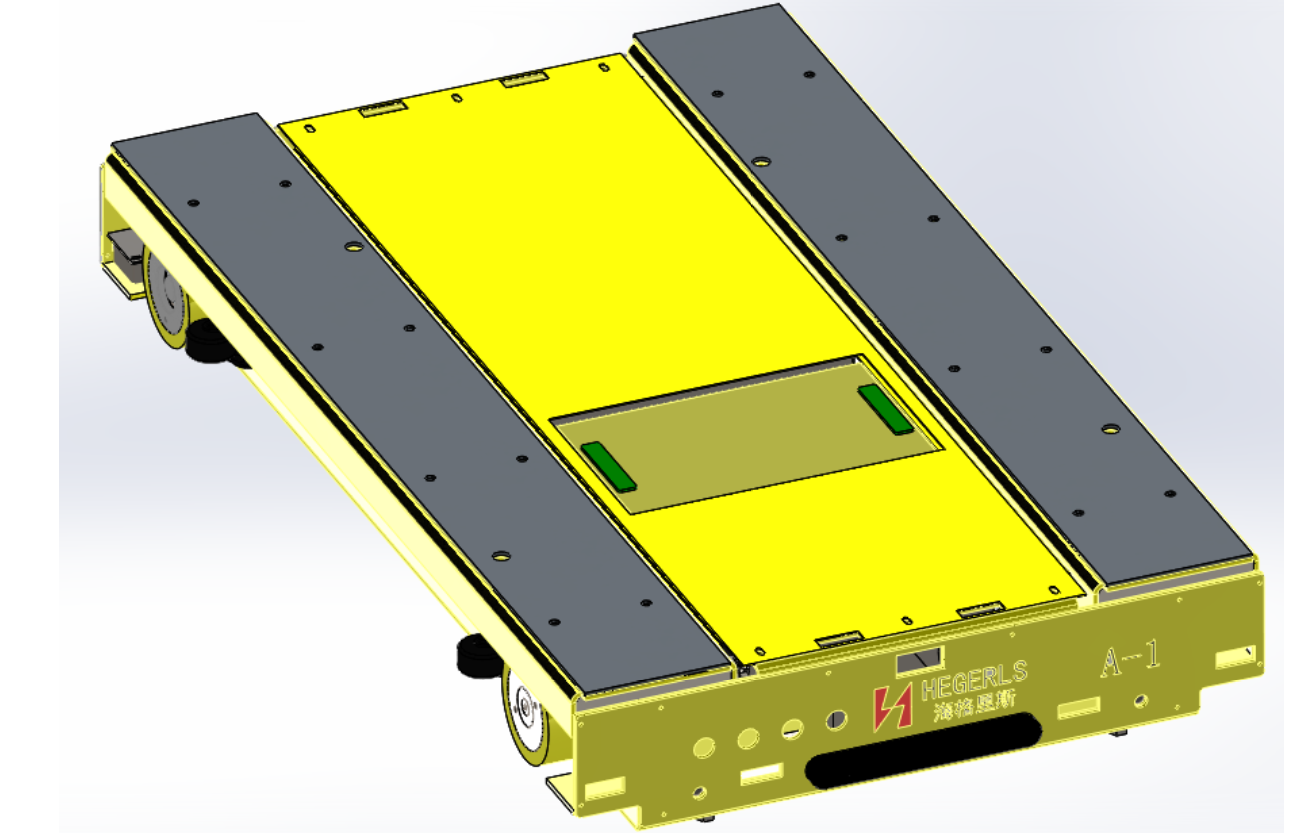

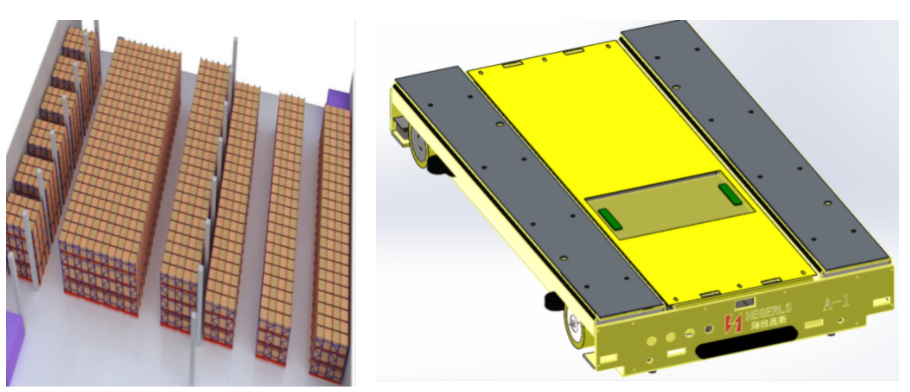

1.Product introduction of radio shuttle runner

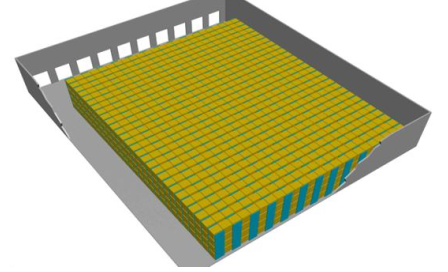

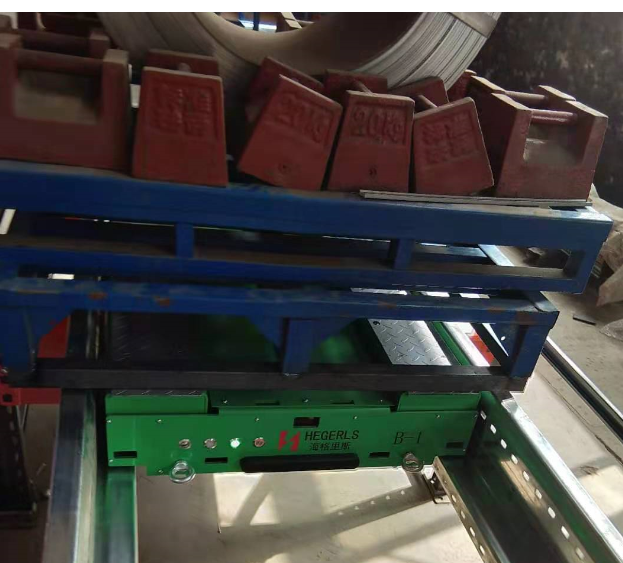

Hegerls radio shuttle runner is high density storage way. It could be first in first out or first in last out. No need too much aisle and could increase the warehouse space utilization 50%.

2.Product parameter.

| Size | Loading | Moving speed | Lift | Battery |

| 1200*1000 | 1500kgs | 0.8-1.2m/s | 6s | Lithium |

3.Product feature and application

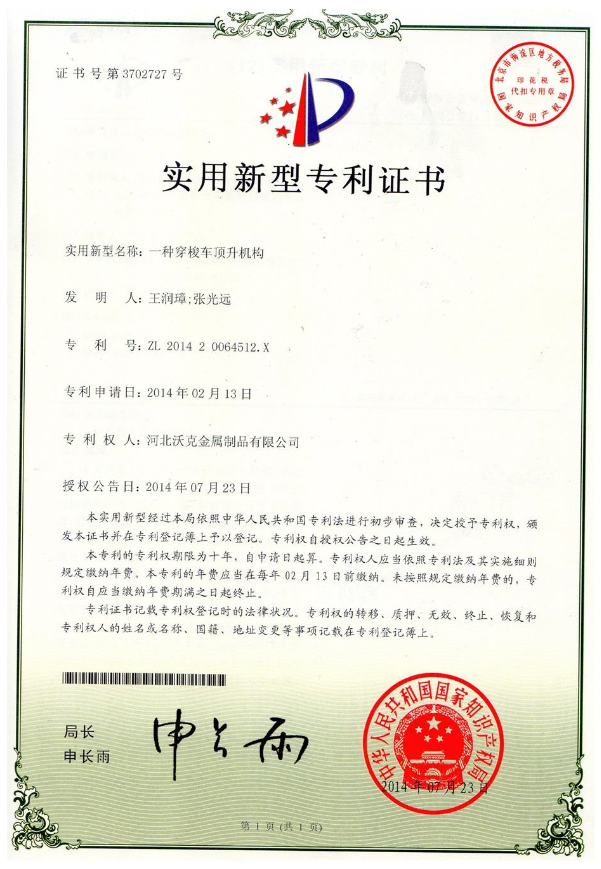

3.1.We have our own patent of radio shuttle racking.

3.2 Radio shuttle racking is high density storage way. the warehouse floor utilization increase 40% compare with traditional selective pallet racking.

3.3 Hegerls radio shuttle racking could be used in ambient warehouse and cold room. The minus temperature could be minus 25 degree.

4.Production detail of radio shuttle racking

4.1 The color could be customized. We have color of black, green and yellow color.

4.2 The pallet size could be W1200*D1000, W1200*D1200, W1100*D1100, The max loading of each pallet could be 1500kgs.

4.3 big 5 functions Input, output, continuous input, continuous output, inventory, move pallet.

4.4 equipment with its own patent lifting mechanism, more efficient, more power saving

4.5 using the German import background suppression of the photoelectric sensor, can identify the black and white color objects, special installation method can identify the plastic tray with holes

4.6 Components self detection function, once a component failure or damage, the device will automatically detect and alarm; system anti-interference ability, in some environmental influence can still successfully finish all kinds of functions

4.7 Come standard with inventory counting function, through the remote real-time display and convenient statistical products, the number of each channel, and support continuous inventory

4.8 Absolute low temperature design: the system adopts anti low temperature design, with moisture function, and no heating device, can work at low temperature -25 degrees, the reliability of 100%

4.9 Equipment inside the machine processing parts are using nickel plating, not only can rust and corrosion protection, especially for the food industry

4.10 With large capacity lithium iron phosphate battery, no memory effect, long life and good security, the number of charging up to 1000 times

4.11 Polyurethane wheels, low noise, wear resistance

5.1 we have passed the certificate of SGS.BV,TUV and ISO quality control certificate.

Furthermore, we also have passed the certificate of environment management, health and safety management

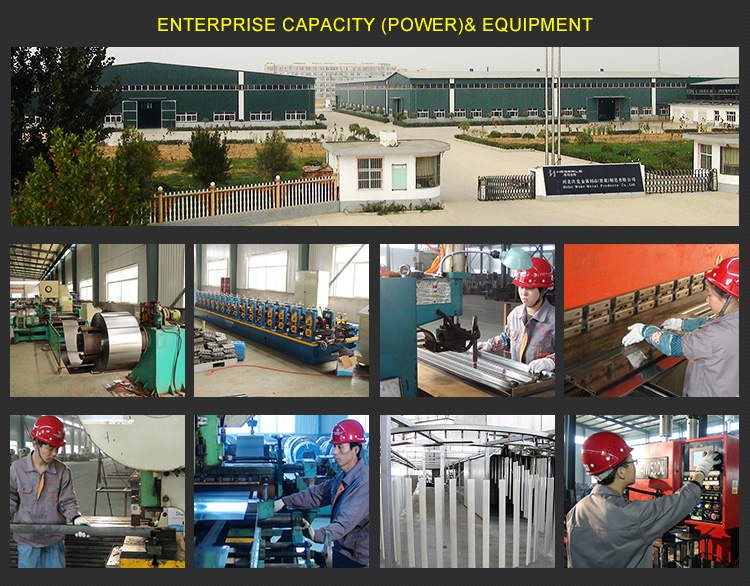

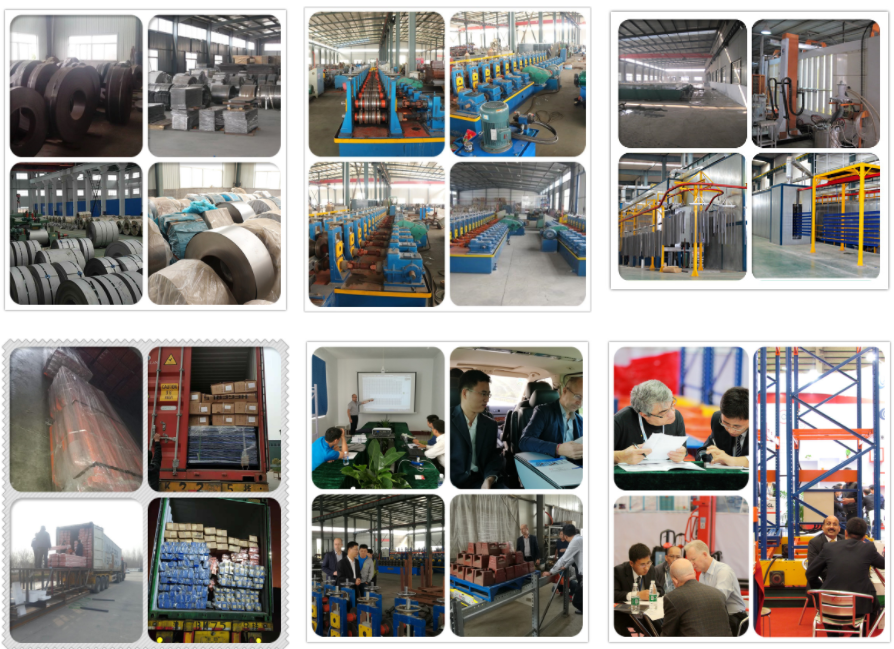

5.2 Raw materials: cold rolled steel Q235B. or international steel standard SS400

5.3. rolling machine. We have 12 sets rolling line, could roll different size.

5.4 Power coating line. It is 500 meters long and the brand of power coating gun is GEMA, which is very famous on the coating field.

5.5 customer visiting. Our location is in hebei province, near to Beijing and Tianjin. Our airport name is Shijiazhuang zhengding international airport. Welcome your visiting any time.

5.6 exhibition. Every year we will attend canton fair and shanghai Cemat fair.

Delivery. Shipping and service

6.1 Packaged and shipping. Normally, the upright will be packed by plastic foams. And shuttle racking will be loaded into wooden pallets.

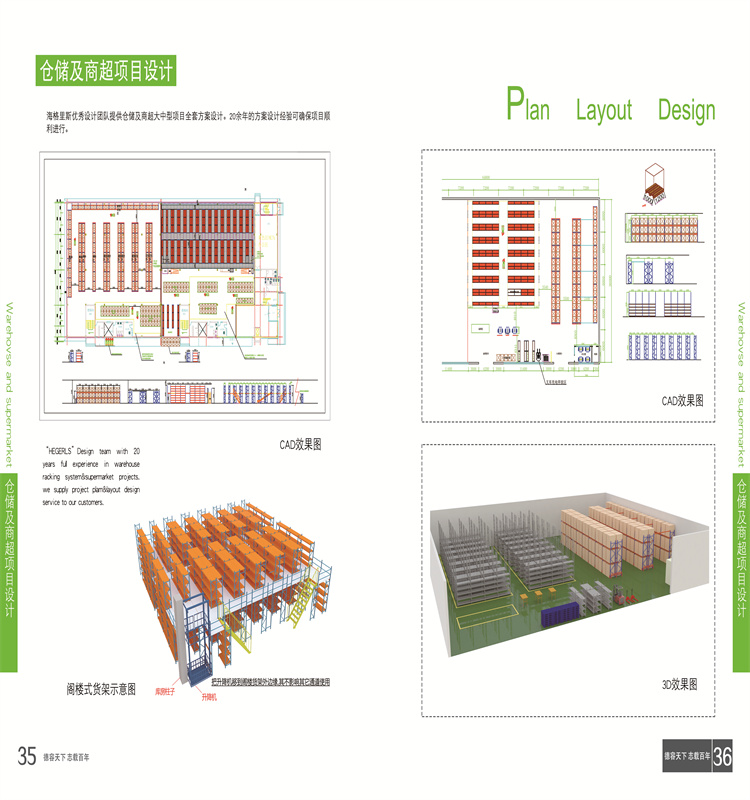

6.2 We provide layout drawing and 3d effect picture

FAQ

Q: What is the quality warranty of your products ?

A: Our quality warranty is 1 years. We will keep on providing the service out of this time and only offer cost of spare parts.

Q: What is the lead time ?

A: For the racking system, it normally take 30 days. And for the shuttle racking, it need 60 days for the production.

Q:Could you provide the layout design ?

A: Yes, we could provide the layout design freely in Autocad or 3d picture. It is our free service.

Q:What color cold be available ?

A: Normally, we have color of blue RAL5005 and orange RAL2004. The color could also be customized. Please provide us your color number.

Q:how about the installation?

A: We will provide the detailed installation drawing. For the simple traditional racking, the workers could install it according to our drawing. Or else, our engineer could go to on site to instruct the installation And buyer will afford the cost.

Latest news

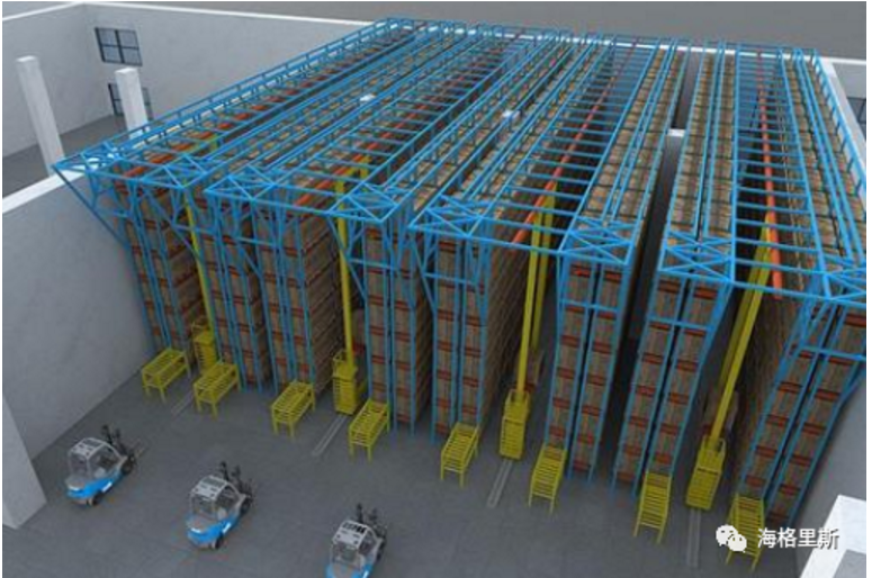

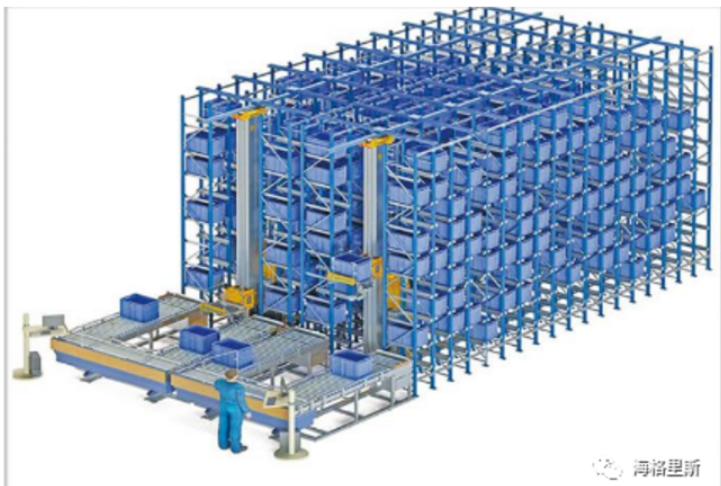

The core equipment of automated warehouse-stacker

Tracked roadway stacking crane is a special crane developed with the appearance of the three-dimensional warehouse, referred to as the stacker, is a very important lifting and handling equipment in the three-dimensional warehouse, and is a symbol of the characteristics of the three-dimensional warehouse. Its main purpose is to run along the track in the roadway of the high-rise warehouse to store the goods at the entrance of the roadway into the cargo compartment; or to take out the goods in the cargo compartment and transport it to the entrance of the roadway to complete the warehousing operation.

There are many types of stacker cranes. In the current three-dimensional warehouse applications, the most common is

1. According to the structure, it is divided into single column structure and double column structure

2. According to the running track classification, it is divided into linear type and curved type

No matter what type of stacker crane is generally composed of horizontal walking mechanism, lifting mechanism, loading platform and fork mechanism, frame and electrical equipment and other basic parts. The walking motor drives the wheels to move horizontally on the lower rail through the drive shaft, the lifting motor drives the cargo platform to move vertically through the chain/wire rope/belt, and the forks on the cargo platform do telescopic movement. The walking address finder is used Control the stacker's horizontal walking position, and raise the address finder to control the lifting position of the loading platform; through the address finder and photoelectric recognition, and the conversion of communication numbers, computer control can be realized, and automatic, semi-automatic and manual control can also be realized through the control panel .

At present, in my country's three-dimensional warehouses, stackers are widely used in industries such as machinery manufacturing, automobile manufacturing, textile industry, railways, cigarettes, and medicine. With the development of modern industrial production, the technology of tracked roadway stacker cranes is constantly improving and perfecting. Since 2017, Hegerls has obtained the new shape and new function stacker patent. It has continued to summarize experience and is committed to development and practicality. We have been very serious about building a three-dimensional warehouse for new products with safety and security!

techical equipments.

Package and loading

Exhibition booth

Customer visiting

Free Layout drawing design and 3D picture

Certificate and patents

Warranty

Normally it is one year. It could also be extended.