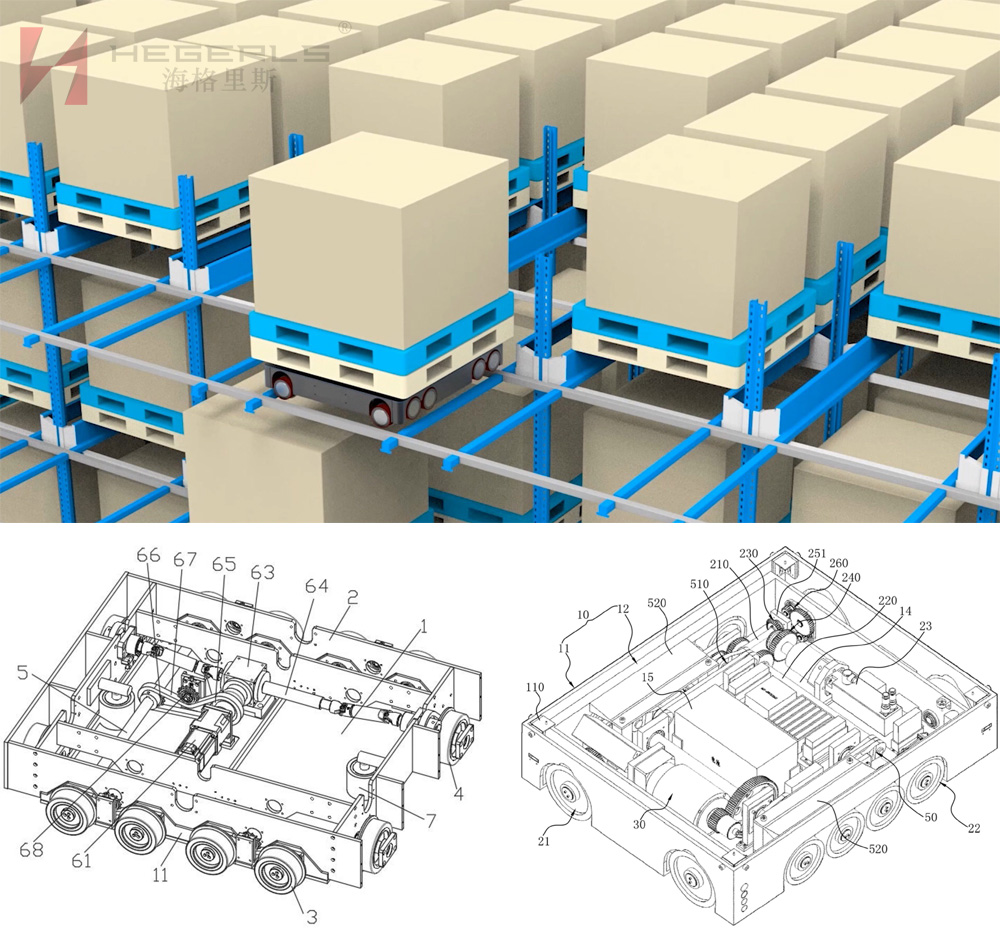

With the rapid development of warehousing and logistics, as well as the e-commerce industry, the types and technologies of automated three-dimensional warehouses are becoming increasingly perfect. In addition to typical single depth and single location three-dimensional warehouses, double depth and multi location three-dimensional warehouses have also gradually developed. In terms of automated storage equipment, in addition to stackers, three-dimensional warehouses composed of technologies such as four-way shuttle cars and parent cars have gradually become accepted by the market, and three-dimensional warehouses using AGVs as access devices are also being vigorously promoted. For large three-dimensional storage systems, four-way shuttle cars have high cost-effectiveness. The four-way shuttle car system flexibly adjusts the operating lanes of the shuttle car, "unbinding" the lanes from the elevator, and solves the bottleneck problem of the multi-layer shuttle car on the elevator. It can also configure equipment completely according to the operating flow, reducing equipment capacity waste, and the cooperation between the shuttle car and the elevator is more flexible and flexible, By increasing the number of small cars, the level of entry and exit can be improved. At the same time, the four-way shuttle overcomes the shortcomings of circular shuttle cars and can achieve fully automatic, intelligent, and unmanned operations. Compared with traditional three-dimensional warehouses, it increases the storage capacity by 20% to 50% and has high flexibility and flexibility. Regardless of whether the outbound volume is small or large, the four-way shuttle truck three-dimensional warehouse solution is very suitable and is one of the future development trends of automated three-dimensional warehouses.

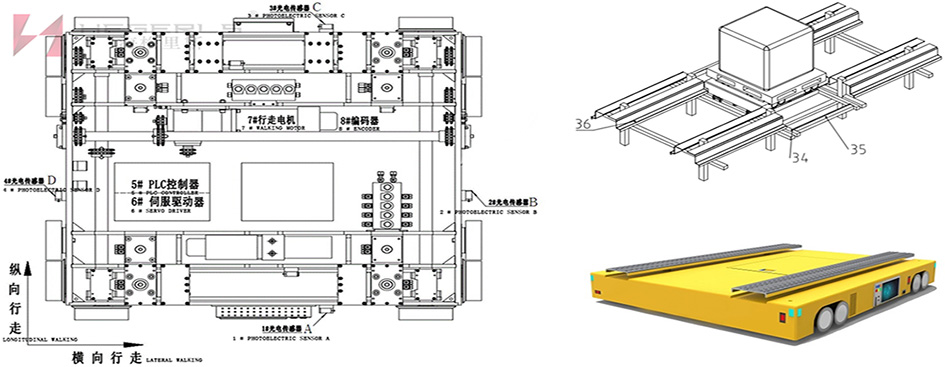

In recent years, more and more four-way shuttle projects have been successfully applied. However, the four-way shuttle system is more complex in control scheduling, order management, route optimization algorithms, and other aspects, making project implementation more difficult. Therefore, there are relatively few manufacturing suppliers. Hebei Woke Metal Products Co., Ltd. (self owned brand: HEGERLS) is the earliest enterprise at home and abroad to focus on four-way shuttle technology. Hebei Woke has always made the four-way shuttle system a key product for research and development, mainly because it wants to break through the technical bottleneck of traditional multi-layer shuttle systems. The multi-layer shuttle vehicle must cooperate with the elevator at the end of the tunnel for operation. In this case, the elevator becomes the "short board of the wooden barrel", and its efficiency determines the throughput and operational efficiency of the multi-layer shuttle vehicle system. Therefore, it is not possible to blindly increase the number of multi-layer shuttle vehicles to improve system efficiency. The HEGERLS four-way shuttle car system flexibly adjusts

the operating roadway of the shuttle car to "unbind" the roadway with the elevator, making the above problems easily solved. That is to say, the HEGERLS four-way shuttle system can fully configure equipment according to the operating flow, without wasting equipment capacity. The cooperation between the shuttle and the elevator is also more flexible and flexible.

The biggest outstanding advantage of the Hagrid HEGERLS four-way shuttle system compared to other package automation solutions is:

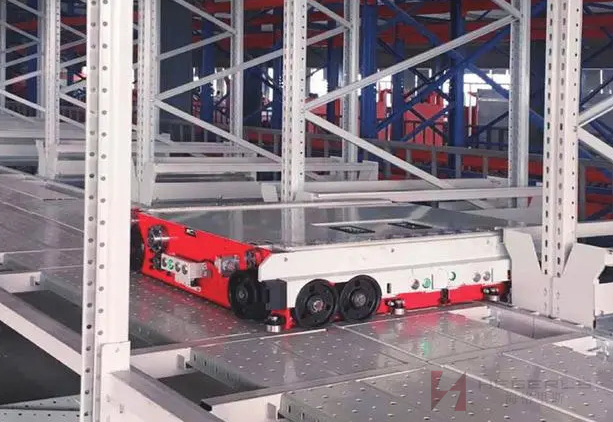

1) The HEGERLS four-way shuttle is equivalent to an intelligent robot, connected to the WMS system through a wireless network, and can go to any cargo location in conjunction with a hoist. Therefore, it is truly a three-dimensional shuttle.

2) The system has higher security and stability. For example, in the traditional multi-layer shuttle car system, if the elevator malfunctions, the entire tunnel operation will be affected; The HEGERLS four-way shuttle system, on the other hand, can continue to

complete operations through other elevators, making the system's capabilities almost unaffected.

3) The flexibility of the HEGERLS four-way shuttle system is also very high. Due to the ability to freely change lanes, the number of shuttle cars can be increased or decreased to adjust the system capacity. In addition, the HEGERLS four-way shuttle system is modular and standardized, with all cars interchangeable and any car capable of continuing to perform the task of a problematic car.

4) In terms of overall system cost, the HEGERLS four-way shuttle system also has significant advantages. Due to the close correlation between the cost of a regular multi-layer shuttle or miniload stacker system and the number of lanes, with an increase in order volume and no increase in inventory, each additional lane in these systems will increase the corresponding cost. However, the four-way shuttle system only needs to increase the number of shuttle cars, resulting in lower overall costs.

Application range of HEGERLS four-way shuttle vehicle

The HEGERLS four-way shuttle is very suitable for use in cold storage, logistics warehouses, and other scenarios, and is another important automation solution after the stacking machine three-dimensional warehouse. The HEGERLS four-way shuttle is also a channel and bridge connecting the work area, production site, and storage area. It has the advantages of high automation, saving manpower and time, convenient and fast operation, and improving work efficiency. HEGERLS four-way shuttle can be used in irregular and irregular warehouses with large length width ratio, high or low warehousing efficiency, or warehouses with few varieties and large batches, and multi varieties and large batches. It has high flexibility and strong site adaptability. It is also used for unit material storage in raw material warehouse, line

side warehouse, and finished product warehouse. It can reasonably use storage space and improve warehouse utilization. It is an intensive warehousing solution. The HEGERLS four-way shuttle vehicle three-dimensional warehouse has the characteristics of large storage capacity improvement, high operational efficiency, rich application scenarios, and high scalability. It can help enterprises achieve the goals of process automation, process visualization, and online and offline integration.

The four-way shuttle car three-dimensional warehouse is a common automated three-dimensional warehouse solution. By utilizing the vertical and horizontal movement of the four-way shuttle car and cooperating with the elevator for layer changing operations, automated cargo entry and exit operations can be achieved. The four-way shuttle bus has high flexibility and can freely change the working lanes. The system capacity can be adjusted by increasing or decreasing the number of shuttle buses. If necessary, the scheduling method of establishing a working fleet can be used to adapt to the peak of the system and solve the bottleneck of inbound and outbound operations for enterprises.

Post time: Jun-12-2023