Hagrid HEGERLS High Speed Shuttle Car Customization on Demand | Four way Shuttle Car Shelves and Child Mother Shuttle Car Shelves Don’t Be Foolish to Distinguish?

With the development of the logistics and warehousing industries, more and more enterprise users are demanding higher levels of warehousing automation. In recent years, various shuttle cars, AGV cars, have also appeared at major logistics exhibitions and are highly favored by users of various small and medium-sized enterprises. In order to further improve the storage rate of warehouse storage, more and more suppliers of warehouse shelves and equipment manufacturing have also conducted in-depth research and development on the basis of existing shuttle technology.

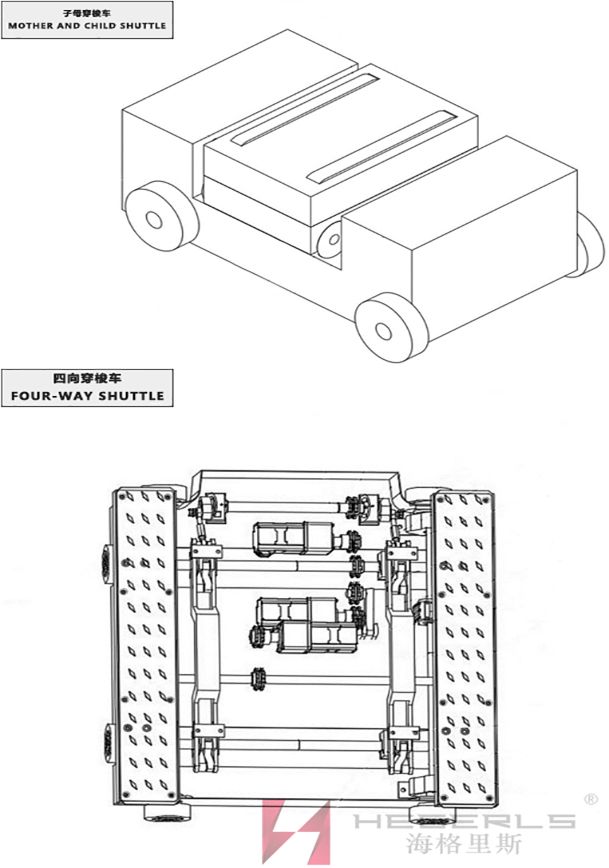

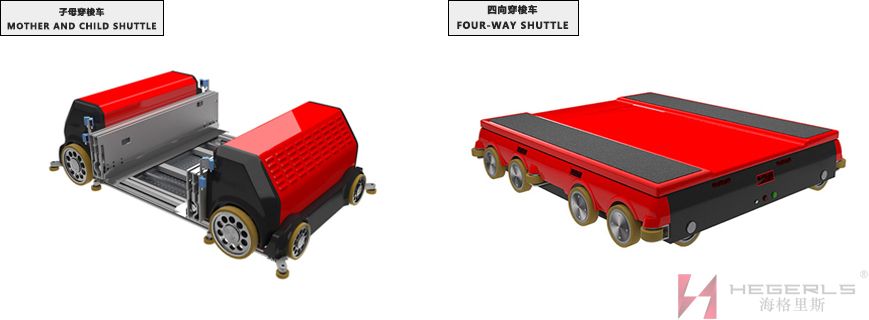

According to the degree of subdivision, shuttle vehicle shelves include three different types of shuttle type shelves, namely bidirectional shuttle vehicle shelves, parent-child shuttle vehicle shelves, and the latest four-way shuttle vehicle shelves. These three types of shuttle shelves are actually developed and improved by the warehousing shelf industry and enterprises in the continuous development process to meet different industry customers and storage needs.

Hebei Woke Metal Products Co., Ltd., as a well-known manufacturer with relevant equipment technology patents, invests a lot of time and cost in the research and development and upgrading of intelligent equipment technology every year. Its own brand (HEGERLS) factory has an automated production line, intelligent management, and a series of products and services covering nearly 30 provinces, cities, and autonomous regions in China. The products are exported to Europe, America, the Middle East, and Latin America Southeast Asian and other countries and regions have achieved remarkable results overseas. The self-designed and produced intelligent shuttle cars, multi-layer shuttle cars, parent-child shuttle cars, four-way shuttle cars, and tunnel stackers have become the designated automated three-dimensional warehouse equipment brands for many enterprises.

HEGERLS Parent and Child Shuttle Vehicle Shelves 3D Library

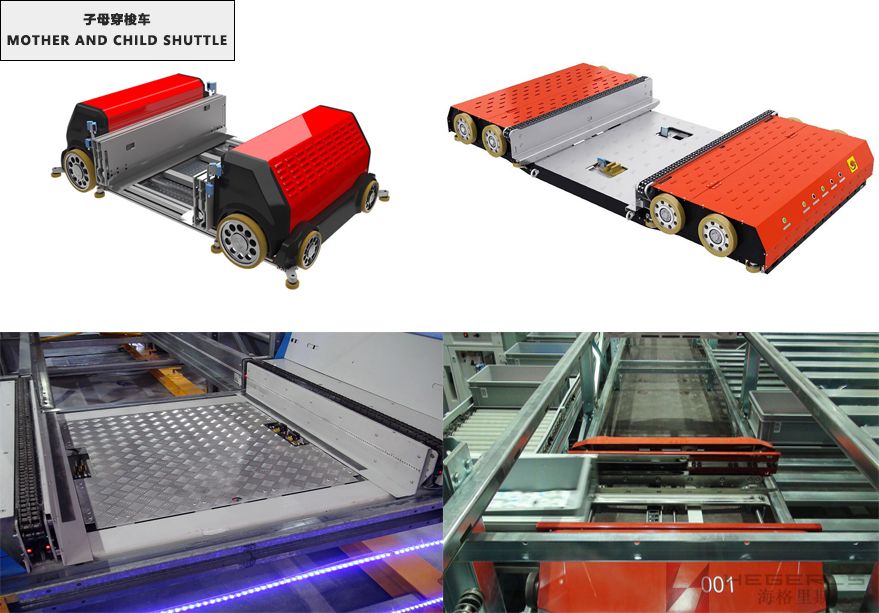

It is composed of components such as shelves, shuttle cars, shuttle mother cars, mother car tracks, elevators, conveyors, WMS management systems, WCS scheduling systems, etc. It is an automated upgraded version of bidirectional shuttle shelves, achieving full automation control and controlled by a computer system. The shuttle car is responsible for storing goods in the tunnel, and the shuttle mother car is responsible for moving goods horizontally into vertical lifting equipment, At the same time, the sub vehicles can switch channels on the same floor through the parent vehicle, or switch layers through vertical lifting equipment, and ultimately complete the logistics docking between the warehouse area and the outside through the ground transportation system.

The child mother shuttle truck rack overcomes the bottleneck in storage efficiency of the bidirectional shuttle truck rack. The shuttle trolley no longer only moves in a straight line, but can move in four directions, front, back, left, and right. It can also automatically change layers and tunnels, achieving a perfect combination of dense storage and automation systems. The requirements for the layout, floor height, and load-bearing capacity of the warehouse building are significantly reduced for the shelves of the shuttle car. At the same time, the flexibility of the warehouse layout combination can also achieve discontinuous floor and multi area layouts, thus achieving fully automated storage.

The HEGERLS shuttle truck shelves also have numerous advantages:

1) Complete backup

The three-dimensional warehouse for the shelves of the mother and child shuttle cars has a complete backup system, and the shuttle cars can improve operational efficiency during real-time selection and switching of various transportation tools to ensure the storage efficiency of goods.

2) Implementing high-density storage

The application of a three-dimensional warehouse with shelves for mother and child shuttle cars can achieve multi-directional and high-density storage of goods, and letter shuttle cars can choose suitable storage locations for goods based on their size. The elevator part of the shuttle carrier rack system can make the storage of goods more convenient, improve the space utilization rate and storage density of the warehouse.

3) Accurate storage and selection

The child mother shuttle truck rack three-dimensional warehouse can sort and mark the stored goods, and provide feedback on the storage data to the picking staff, helping them to quickly and accurately access goods and improve the efficiency of warehouse operations.

4) Improve work efficiency

The application of the child mother shuttle vehicle shelf system can increase the processing capacity of the warehouse by more than 9-10 times. Compared with other shuttle cars, the parent-child shuttle car has significant structural optimization, greatly improving the working speed of the equipment, so the processing capacity of the entire warehouse can be greatly improved.

5) Save time and costs

The fast processing ability of the mother and child shuttle saves a lot of time and costs, as well as reduces the operating time of the staff, which can save more abundant time for other work in the warehouse.

HEGERL four-way shuttle truck rack three-dimensional warehouse

It is a further upgraded version based on the shelves of the mother and child shuttle. According to the principle, the shelves of the mother and son shuttle cars have achieved a perfect combination of dense storage and automated storage. Why did the four way shuttle car shelves appear again? Although the rack of the parent-child shuttle vehicle has achieved dense storage and full automation in terms of functionality, its structure and composition are somewhat complex. It has both parent-child and parent-child vehicles, and the system’s safety and stability are not high. When a malfunction occurs, maintenance is both troublesome and costly. Not only developers, but also enterprise users hope to further simplify the structure of the parent-child shuttle vehicle rack, At the same time, it can also achieve intelligent and operational robots, which has led to the emergence of four-way shuttle racks. Since its introduction to the market, the four-way shuttle rack has been highly favored.

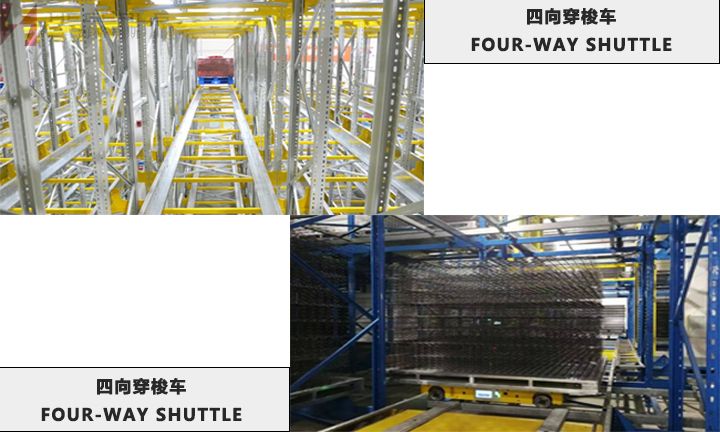

The four-way shuttle car is equivalent to an intelligent transportation robot, which is connected to the WMS system through wireless network. A car can complete tasks such as picking up, transporting, and placing goods, and can go to any cargo location in conjunction with a hoist. It can achieve dual track operation in both horizontal and vertical directions. Combined with identification technologies such as RFID and barcode, it achieves automated identification and dense storage. This device can achieve automatic lane changing and layer changing, automatic storage and unloading of goods, automatic climbing, and can also be transported and driven on the ground. It is a generation of intelligent transportation equipment that combines multiple functions such as automatic stacker, unmanned guidance, and automatic transportation. The shuttle robot needs to run on a fixed track, which makes the vehicle faster, more accurate in positioning, and easier to control. The four-way shuttle can not only achieve movement in four directions, but also flexibly schedule according to specific application environments. For example, it can be reasonably utilized in some irregular activity venues, which reflects the greater range of application and better flexibility of the four-way shuttle. Of course, the four-way shuttle can also change the operating track, avoid vehicles, change layers, and other functions. By increasing or decreasing the number of shuttle vehicles, the system capacity can be adjusted. If necessary, multiple operating vehicles can be formed to form a scheduling method for the operating fleet, to adapt to the peak of the system and solve the disorder of entry and exit operations.

Hebei Woke has also solved many warehouse warehousing problems for major enterprises in recent years due to its unique four-way shuttle intelligent dense storage system and special solutions. The Hagrid HEGERLS intelligent four-way shuttle can automatically switch between longitudinal storage tunnels and transverse transfer channels in a 90 degree direction, making it more suitable for warehouse storage modes in complex terrain environments; Because each single machine and unit of Hagrid HEGERLS are interconnected with the support of wireless network, and can only be coordinated with each other to complete the inbound and outbound work of goods in a first in, first out or first in, last out manner under the scheduling of the WMS WCS upper management and control system. And the HEGERLS intelligent four-way shuttle intelligent dense storage system is composed of a horizontal conveying system, a shelf system, a four-way shuttle, a fast vertical elevator, and its WMS/WCS management and control system. Don’t underestimate such a system. The biggest advantage of this system is its high storage density, stable system operation, high security redundancy, and strong scalability for inventory efficiency in the later stage. At the same time, it has been widely used in industries such as e-commerce logistics, refrigeration, textile shoes and clothing, automotive parts, hardware and building materials, equipment manufacturing, and military supplies.

In summary, each enterprise still needs to choose a shuttle vehicle suitable for their own cargo transportation based on their actual needs, investment costs, technical requirements, warehouse management, and comprehensive consideration of all aspects. Of course, if corporate customers are unsure what type of automated warehouse to choose, or if there are still some doubts in certain aspects, they can call Hebei Woke Metal Products Co., Ltd. for consultation. At that time, professional technicians and sales personnel with automated warehouse related skills will conduct free on-site inspections, based on the company’s goods specifications, frequency of goods entering and exiting the warehouse Plan and design an automated three-dimensional warehouse suitable for the enterprise based on the actual data situation, such as warehouse location.

Post time: Apr-19-2023