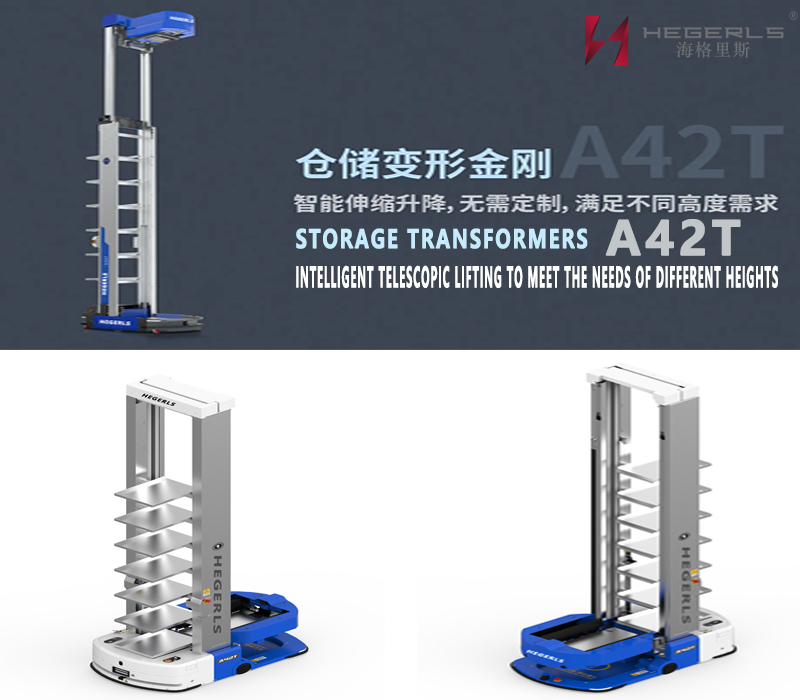

With the rise of warehouse rent, the importance of storage density to logistics warehouses will continue to rise. It is this concept and awareness of focusing on customers that prompted the hegerls team of haggis to start the research and development of the telescopic lifting bin robot. The release of hegerls a42t, a telescopic lifting container robot, is the product of hegerls' continuous gathering of customers' storage pain points, marking another innovation of hegerls' box storage robot products, helping more enterprises realize the automation transformation of storage, improve storage density, and create ultra-high flexible storage.

Telescopic lifting bin robot hegerls a42t

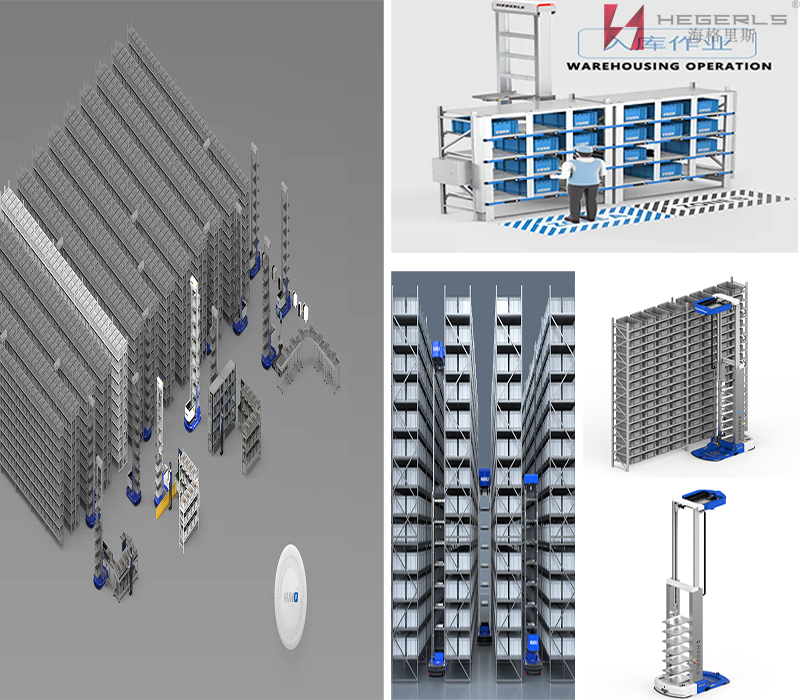

Kubao hegerls a42t telescopic lifting box robot, independently developed by haggis, is designed to improve the storage density of a 10 meter high warehouse. Its pickup height covers 0.35m~8m, realizing the picking, storage and handling of material boxes in irregular and unequal height warehouses, flexibly covering the ultra wide three-dimensional storage space, and greatly improving the storage utilization rate. As a new intelligent logistics handling equipment, hegerls a42t can realize intelligent walking in the storage space without the help of any track equipment, and has the functions of autonomous navigation, active obstacle avoidance and automatic charging. Intelligent algorithm optimizes the efficiency of high and low cold and hot storage locations and cross region access and sorting, so as to ensure the efficiency of robots in irregular and unequal warehouses. Compared with the traditional AGV "shelf to person" solution, kubao robot picking granularity is smaller. According to the order requirements issued by the system, it really realizes the transformation from the traditional "people looking for goods" to an efficient and simple "goods to person" intelligent picking mode. Compared with the solutions of stacker and automatic three-dimensional warehouse, kubao robot system can realize efficient deployment, with low overall deployment cost and stronger flexibility; At the same time, hegerls a42t supports the docking of a variety of logistics equipment, including shelves, latent AGVs, robotic arms, multi-function workstations, etc. Flexible product design brings more operating space for customized solutions, comprehensively improves the efficiency of warehousing operations, optimizes the density of warehousing, and realizes the automation and intelligent transformation of the warehousing industry. Applicable scenarios: it is suitable for warehousing applications in 3PL, shoes and clothing, e-commerce, electronics, electricity, manufacturing, medical, retail and other industries, especially for irregular and unequal height warehouse scenarios, as well as scenarios where robots need to flexibly pass through fire-fighting areas and carry elevators

Functional characteristics of telescopic lifting bin robot hegerls a42t

The highest pickup height is 8 meters, with ultra wide three-dimensional storage space;

Multi container handling, single machine access handling up to 8 containers;

Dynamic width adjustment fork design, compatible with multi size cartons / bins.

Hegerls a42t, a super flexible and telescopic lifting box robot

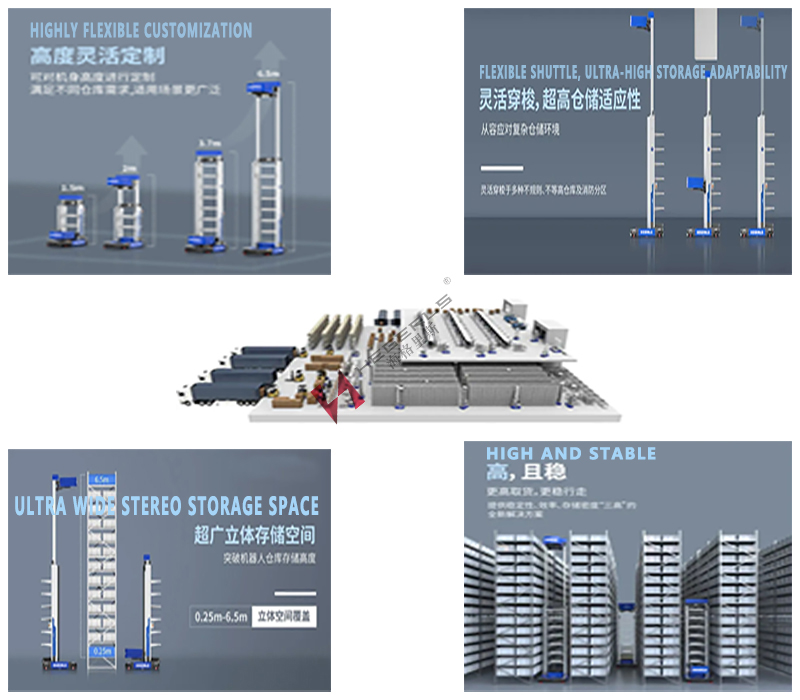

1) No modular customization, intelligent telescopic lifting

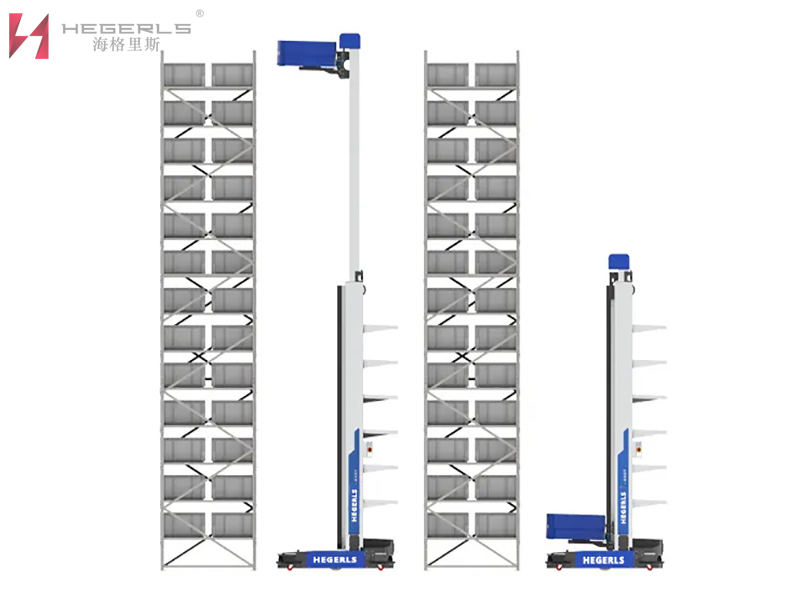

Compared with the modular customized robot, the telescopic lifting bin robot hegerls a42t has the intelligent telescopic lifting function. The 3.7m body can be raised to 6.5m, maximizing the use of warehouse space and realizing ultra-high flexible storage.

2) 0.25m to 6.5m, ultra wide stereo storage space coverage

The telescopic lifting bin robot herls a42t once again breaks through the storage height of the robot warehouse. The minimum access range of the robot is as low as 0.25m, and the maximum can reach 6.5m, realizing ultra wide three-dimensional space coverage and improving storage density.

3) High and stable

To improve the quality, we should be more safe and reliable. The telescopic lifting bin robot herls a42t can realize the access, handling and sorting of the bins on the 6.5m shelf. At the same time, the height of the body is only 3.7m. The robot walks more stably and quickly, providing a new solution of "three high" stability, efficiency and storage density.

4) Flexible customization is possible to meet a variety of needs

Hegerls a42t, a telescopic lifting bin robot, provides flexible customization services, which can customize the height of the body to meet the different needs of each warehouse, and is applicable to a wider range of scenarios.

Beyond possibility · unlock all kinds of storage needs

1) Intelligent adaptive irregular warehouse, ultra-high storage adaptability

Hegerls a42t, a telescopic lifting box robot, further improves the storage adaptability, flexibly shuttles through a variety of irregular and unequal height warehouses, calmly copes with the complex storage environment caused by fire pipes, building beams, etc., reduces the threshold of storage automation transformation, gives play to the limit of storage density, and enables more storage.

2) Fire protection / fire compartment, efficiency not zoning

The fire / fire compartment in the warehouse is easy to lead to the uneven efficiency of the two zones. The unique telescopic lifting function of the telescopic lifting bin robot herls a42t helps the robot easily shuttle between the two sides of the fire compartment, flexibly respond to the efficiency requirements of different storage areas, realize the mutual transfer of robots between the partitions, and achieve the highest utilization rate.

3) Take the elevator and shuttle up and down freely

Hegerls a42t, a telescopic lifting bin robot, has the function of carrying elevators, realizing the free shuttle between upper and lower floors, covering a wider range of storage operations, and can realize the docking of different floor warehouses and production lines. Combined with customized solutions, it can meet the needs of customers.

4) Convenient transportation and rapid deployment

The "compact" size of the telescopic lifting bin robot hegerls a42t makes it easier to transport and handle, improves the deployment speed, improves the efficiency of the overall project implementation, and reduces costs and increases efficiency for customers in a faster way.

Hegerls

Hagerls has been committed to providing efficient, intelligent, flexible and customized warehousing automation solutions through robotics and artificial intelligence algorithms, creating value for each factory and logistics warehouse. Haggis focuses on the R & D and design of box storage robot system, realizing the independent R & D coverage of core elements such as robot ontology, bottom positioning algorithm, control system, robot scheduling, intelligent storage management system, and has carried out patent layout. Kubao system is the first box storage robot system developed and put into commercial use. It has been applied to 3PL, shoes and clothing, e-commerce, electronics, electricity, manufacturing, medical and other industries. Using kubao system, customers can realize the automatic transformation of the warehouse within a week, increase the storage density by 80% - 130%, and improve the working efficiency of workers by 3-4 times.

Post time: Jul-01-2022