Forklift stereoscopic warehouse is a kind of mechanized storage mode that uses high-rise stereoscopic shelves to cooperate with forklift operation. Compared with the high cost and difficult maintenance automated three-dimensional warehouse, the forklift three-dimensional warehouse has the advantages of less investment, quick effect, low cost, easy maintenance and flexible access. However, most of the operations of this three-dimensional warehouse depend on human eye addressing and manual operation of mechanical equipment. The operation efficiency is relatively low and error prone. The update of warehouse information also needs to be manually entered, and the relevant data information of the warehouse is difficult to be processed quickly and accurately. In view of this situation, Hebei hegris hegerls storage shelf manufacturer proposed a transformation scheme. Through the modification of various equipment of forklift stereoscopic warehouse, a complete stereoscopic warehouse information management and control system was established to improve the information level of stereoscopic warehouse, so as to achieve the purpose of improving the system processing efficiency. The forklift stereoscopic warehouse reconstructed by hegerls storage shelf manufacturer mainly aims at realizing the guidance operation of forklift, automatic perception of stereoscopic warehouse information and computer management, and comprehensively uses the Internet of things technologies such as sensors, automatic identification and wireless communication.

About hagerls storage shelf manufacturer

Hebei Walker metal products Co., Ltd. is a large professional manufacturer committed to providing planning, design, manufacturing, installation and maintenance services for the warehousing and logistics system. Strong technical force and mature after-sales service have won unanimous praise in the industry. It is a shelf manufacturer in North China. At present, the company has a production plant in Xingtai, Hebei Province, a 60000 ㎡ production and R & D base, 48 world advanced production lines, more than 300 people engaged in R & D, production, sales, installation and after-sales, including nearly 60 people with senior technician and senior engineer titles. Established in Shijiazhuang, Hebei Province, the sales center is committed to building a one-stop service supply platform for China’s industrial logistics and warehousing.

Based on quality, guided by market demand, driven by R & D and innovation, and centered on brand management, Hebei Walker adheres to providing customers with high-quality products. In recent years, it has designed, manufactured and installed a series of warehousing and logistics projects for domestic well-known enterprises such as Sinopec, PetroChina, Coca Cola, YIHAI KERRY, Alibaba rookie logistics, JUNLEBAO, jinmailang, North China pharmaceutical, Lucky Film, Yuantong express, Inner Mongolia Xinhua Publishing and distribution group. Successively designed, developed, produced and processed warehousing and logistics products and related supporting facilities for Alibaba rookie logistics Jiangmen large turnover center project, Shanxi automobile transportation group “smart cloud warehouse” large series warehousing and logistics project, beiren Group Logistics Park project, Guoda Group Logistics Center, YIHAI KERRY (Nanchang, Xi’an) logistics reserve project, Yuantong Express warehouse 9 series warehousing and logistics project.

The main brand of Hebei walker is hegerls. Its main products are: industrial shelves (including beam shelves, corridor shelves, shelf shelves, attic shelves, cantilever shelves, steel structure platforms, self sliding shelves, etc.), steel pallets, warehouse cages, smart frames, folding racks, logistics trolleys, industrial cars, tool cabinets, material sorting series and other working position appliances, which are suitable for large warehouses and cold storages, Production workshops and various types of enterprise warehouses.

About the transformation plan for cross stereoscopic warehouse by hegerls storage shelf manufacturer

Composition of cross stereoscopic Library

The system of the cross three-dimensional warehouse is mainly composed of storage system, transport access system and management control system, as well as other supporting subsystems such as power supply, alarm and corresponding operators. The three main systems are as follows:

1) Storage system

The main body of the storage system is three-dimensional shelves and pallets. The system mainly adopts the beam type shelf, which divides the warehouse shelf into multi-layer, multi row, multi column and multi location according to the vertical direction, depth direction and width direction. Among them, single-layer four-way forking pallets are mostly used, and the size of the pallet follows the recommended national standard gb/t2934-1996, which is 1200mm*1000mm*170mm.

2) Transport access system

The main body of the transportation and access system of the forklift three-dimensional warehouse is the forklift, which is responsible for the horizontal handling of pallet goods in the warehouse area and the vertical access in the shelf area. The system adopts a 1-ton battery forklift driven by electricity, with a maximum bearing capacity of 1000kg and a maximum lifting height of 2400mm.

3) Information management and job scheduling system

The information management and job scheduling system is responsible for the processing and management of warehouse information, job scheduling and monitoring, etc. The forklift stereoscopic warehouse (traditional mechanized warehouse) before the informatization transformation has a low informatization level. Only the management computer stores the material information and storage location information of the stereoscopic warehouse. If there is an issue / receipt task, the computer generates a paper issue / receipt document, and the operator searches for the location according to the operation document to complete the issue / receipt operation; After the operation is completed, the administrator needs to manually update the inventory information and location occupancy to complete the issue / receipt management.

The biggest point of hegerls storage shelves in the production and transformation of forklift stereoscopic warehouse is that it reduces the enterprise’s investment cost in forklift stereoscopic warehouse and improves the feasibility of work efficiency. In the scheme design, hegerls technicians mainly follow the following principles, namely:

1) Simplicity principle: refit on the basis of the original system without changing its original equipment configuration to reduce the difficulty of transformation;

2) Safety principle: select facilities and equipment that meet their functional needs in strict accordance with relevant national technical standards and specifications, and pay attention to safety and confidentiality;

3) Economic principle: meet the requirements of low cost, short construction period, low maintenance cost, energy conservation, environmental protection, practicality and efficiency.

Overall scheme for transformation of hegerls forklift stereoscopic warehouse

Hegerls has transformed the forklift stereoscopic warehouse from three aspects: information perception, information transmission and information processing, and built a complete information management and control system, so as to change the traditional mode of manual information collection and manual data entry in the warehouse, guide the forklift addressing, and improve the operation efficiency.

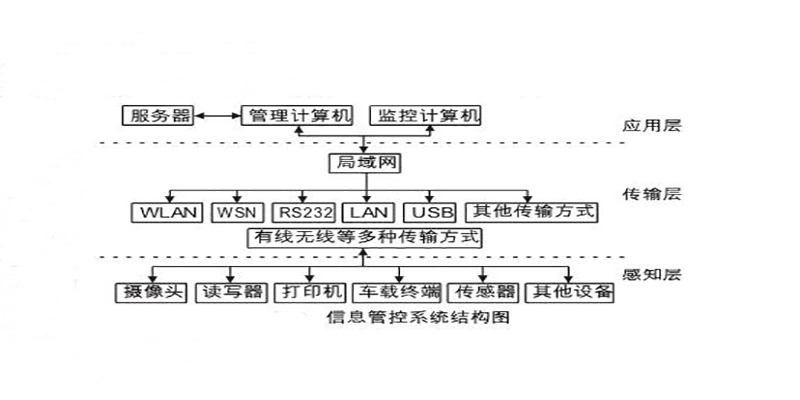

The system hierarchy designed and reconstructed by hegerls is mainly divided into perception layer, transmission layer and application layer from bottom to top. The sensing layer includes various operation devices and terminals, which are responsible for collecting information and feedback upward; The transmission layer comprehensively adopts wired, short-range wireless communication technology and other communication technologies to connect the sensing network with the LAN to realize data transmission; The application layer includes the management computer and the monitoring computer, which are responsible for the processing of information and the issuance of instructions to meet the needs of various users’ application processing and information services.

Specific scheme design of hagerls forklift stereoscopic warehouse

The specific scheme of hegerls forklift stereoscopic warehouse mainly includes three points, namely, the use of bar code labels to identify materials and equipment, the installation of readers and vehicle terminals for forklifts, and the information management system of stereoscopic inventory. Details are as follows:

1) Automatic information perception

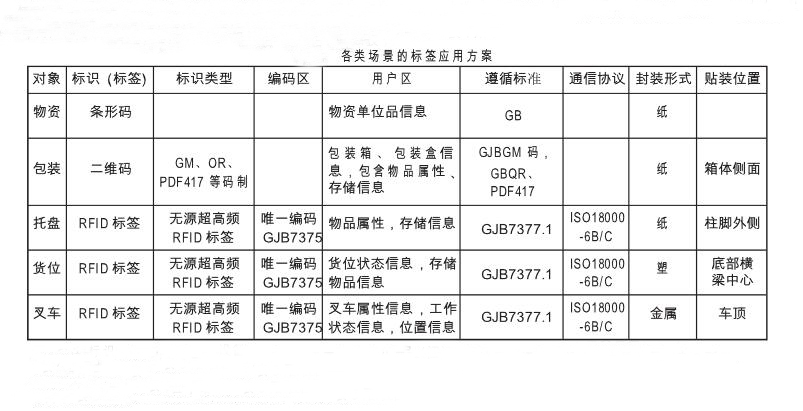

Automatic information sensing mainly includes: location status information, pallet storage information, cargo attribute information and forklift location information. Among them, barcode labels are mainly used to identify goods and equipment, so as to achieve the purpose of automatic information identification.

- label selection and installation

The label consists of coding area and user area. The coding area stores the unique code of the label, which is equivalent to giving a unique ID to the identification object; The user area can store information such as the ownership of items as required.

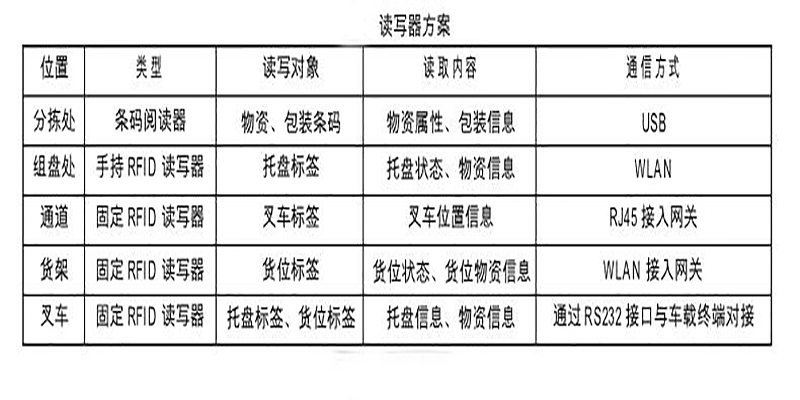

- reader writer scheme

After adding signs (labels), it is also necessary to equip or install read-write equipment at the undetermined position. For mobile equipment, it is only necessary to equip workers, while for fixed equipment, it is also necessary to scientifically design its installation position:

*As for the readers and writers installed in the channel, through experiments, we can see that if the installation is too few, the forklift will not be able to locate, and if the installation is too many, it will generate waste. Therefore, 9 readers and writers are used to distribute on the transportation channel.

*For the readers and writers installed on the shelves, the scheme adopted is: regard the two rows of adjacent shelves as a shelf group, arrange readers and writers at the central intersection of the width direction and height direction of the shelf group, and arrange five readers and writers along the length direction of the shelf in turn, so that the reading and writing range of the readers and writers covers all cargo location labels.

*The reader / writer on the forklift is fixed on the top of the fork baffle and moves with the fork. The position of the Red Cross is the position of the reader / writer. Since the label to be read by the reader / writer is close, the reader / writer range can be adjusted to 1m.

In this regard, this scheme designed by hegerls of hagris, namely, labeling materials and equipment, installing readers and writers to read label information, reasonably selecting the number of readers and writers, and arranging the location of readers and writers, has realized the automatic identification of various information.

2) Forklift guided operation

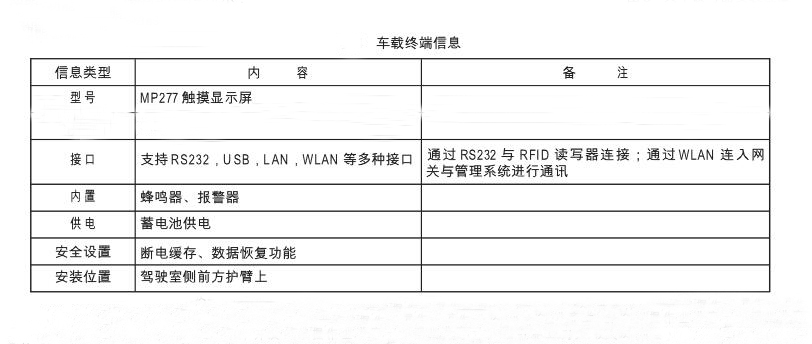

Hagerls mainly guides forklift operation from two aspects: first, the operation path is presented to operators in the form of pictures; Second, the system will give a warning when the forklift is in place and the operation is completed, and give a warning when the operation is wrong. These two functions can be realized by installing the forklift truck mounted terminal. The on-board terminal can realize the following functions:

- display function

The on-board terminal can not only display the real-time position of the cargo space to be operated and the forklift, but also display the shortest path between them. The on-board terminal is like a navigation system to guide the operators to work and master the work progress in time.

- reminder function

The on-board terminal has a built-in buzzer and alarm to remind the operators of the completion of the operation by cooperating with the photoelectric sensor on the fork.

When the forklift is working, the terminal will send the following reminders: when the cargo information is read; Forklift reaches the designated position; The forks arrive at the designated compartment; The goods arrive at the designated location.

Of course, when the forklift truck has the following problems during operation, the on-board terminal will also issue an error warning, that is, the goods have not been stored in the designated location; Pick up error.

In fact, the guidance function of the vehicle terminal avoids the process of human eye addressing to the greatest extent, reduces the labor intensity, and significantly increases the operation speed; The reminder function not only reduces the error rate, but also improves the overall operation efficiency of the three-dimensional library.

3) Computer management of information

The computer management of warehouse information is realized through the development of warehouse management system (WMS). The warehouse management system is an application software system used to manage the personnel, inventory, warehousing tasks, orders and equipment in the warehouse. The information of each business link in the warehouse is summarized in the form of electronic documents, which are uniformly managed by the management system. The management system of forklift stereoscopic warehouse is mainly composed of the following functional modules: user management module, operation management module, system maintenance module, parameter setting module and comprehensive query module.

The scheme designed by hagerls communicates the data of readers, writers, vehicle terminals, etc. with the management computer through the access gateway, and then uses WMS to carry out data processing, information management and job control, making the information processing of the three-dimensional library a complete system, realizing the computer management level of warehouse information, and providing reference and use for the warehouses of major enterprises.

Post time: Jun-16-2022