With the acceleration of product development by domestic and foreign enterprises, as well as the dual wheel drive of new technologies and industrial policies, the pallet four-way shuttle market has opened a new chapter, and in recent years, it has been put into use by various large, medium-sized, and small enterprises. However, due to the automated storage of the pallet four-way shuttle rack, which is relatively expensive in terms of price, enterprises usually ask about the price before building it. So how much is it to customize a set of pallet four-way shuttle rack? How much is the price of the explosion-proof tray four-way shuttle robot? Let’s take a look together.

With the rapid development of the logistics and transportation industry, the pallet type four-way shuttle vehicle is an intelligent mobile AGV model designed for corresponding unmanned warehouses that can travel in four directions. It can inspect and transport goods in an integrated cargo warehouse, as well as carry out corresponding transportation work. If users want to purchase this type of pallet type four-way shuttle vehicle, they need to have a certain understanding of the characteristics of this type of intelligent mobile AGV model, in order to better grasp the practical performance of this type of vehicle in the later use process. Among them, the intelligent scheduling algorithm, the better pallet four-way shuttle vehicle in the industry, has been practiced in the research and development process of corresponding smart chip technology, and is a class of products with intelligent service effects. The intelligent tray type four-way shuttle can freely traverse the shelves by installing high-precision rails on traditional shelves; The guide rail has both cargo transportation and cargo storage functions, which greatly improves the utilization rate of storage space. Generally, high-quality pallet four-way shuttles have a long retention time and usage time. Due to the wide range of inventory temperatures available for use, they can operate the vehicle body and transport goods in corresponding normal temperature warehouses, low temperature and high humidity warehouses, and refrigerated warehouses. With better manufacturing techniques, the impact of temperature and humidity on the vehicle body’s load-carrying operation is reduced, helping to improve the control effect of temperature and humidity on the vehicle body. When establishing a relevant unmanned warehouse, users need to seek appropriate and convenient control and cargo transportation, so they need to conduct prior investigation on this type of vehicle to help clarify the specific performance of the vehicle’s heavy haul performance during the selection process. The main reason for the high utilization rate of Hebei Woke intelligent pallet type four-way shuttle vehicles is that the equipment can effectively transport goods, ensure the reliability of goods, and meet the warehousing needs of enterprises.

Hebei Woke Metal Products Co., Ltd. is a combined service that integrates services such as four-way shuttle robots, hoists, shuttle shelves, and three-dimensional warehouses. It is one of the enterprises with certain strength in machinery and industry equipment, mainly providing products or services in the fields of four-way shuttle vehicles, machinery, elevators, shuttle shelves, and three-dimensional warehouses. At the same time, Hebei Woke aims to provide users with more and richer mechanical and industrial equipment products in several major fields such as four-way shuttle robots, elevators, shuttle shelves, and three-dimensional warehouses, further providing more targeted mechanical and industrial equipment services to more enterprises at home and abroad. Hebei Woke has always maintained a priority in the field of machinery and industrial equipment, and continuously optimized its business structure. After more than 20 years of development, Hebei Woke has undertaken a large number of high-end projects in the fields of four-way shuttle robots, elevators, shuttle shelves, and three-dimensional warehouses, actively providing services to more machinery and industry equipment enterprises.

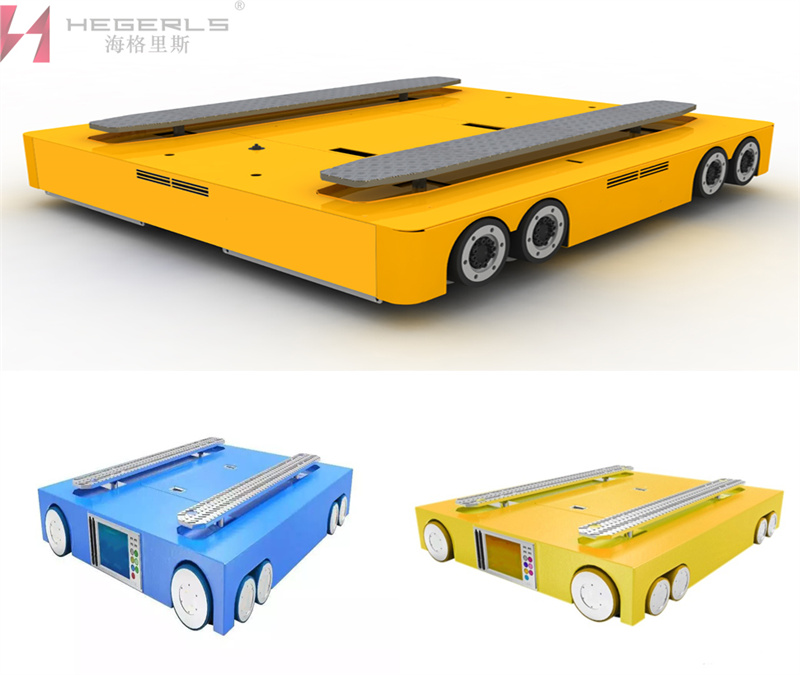

HEGERLS manufacturer explosion-proof tray four-way shuttle robot price

Compared to the price of the explosion-proof tray four-way shuttle robot produced by HEGERLS, it is difficult to understand the structural design of the tray four-way shuttle. It is necessary to rely on finite element analysis to assist in the analysis, especially the driving stability analysis of the entire vehicle, which is currently only based on the simulation test of driving conditions, and cannot be systematically studied theoretically. The motion vibration of the entire vehicle is mainly concentrated in the drive and hydraulic parts, and its wheel axles and bearings are prone to vibration fatigue damage. The main reasons are that there are joints and installation deviations in the rails configured in the steel rack, and there are certain elastic deformations in the rack structure. The contact stiffness between the wheels and the rails is relatively large, which can easily cause wheel rail contact vibration and vehicle body vibration. Currently, measures such as rubber coated wheels are commonly used to optimize wheel group resonance. Moreover, there is the high capacity battery technology, which is one of the key technologies affecting the application of the four-way shuttle vehicle. The pallet four-way shuttle truck stores and transports pallet units with heavy loads, high power consumption per unit of travel, and the working time that can be met per full charge has become a bottleneck in the widespread application of the four-way shuttle truck. Effectively monitoring the health status and charging and discharging performance of lithium batteries on the four-way shuttle is also one of the key technologies to ensure the full automation of the tray four-way shuttle automated intensive storage system. High performance and high capacity batteries are expensive, making the manufacturing cost of the tray four-way shuttle high. Due to its technical accuracy requirements and scheduling issues, the tray four-way shuttle vehicle has increased installation time, technical threshold, and cost; Moreover, in terms of shelves, pallets on four-way shuttle trucks may be more expensive; The software aspects of the pallet four way shuttle are also more complex.

The Hagrid HEGERLS tray type four-way shuttle generally has two sets of gear trains, one for traveling in the X direction and the other for traveling in the Y direction. When the car runs on the track and encounters a turning point, it is completed by changing the gear train. Therefore, the direction of the cargo unit remains unchanged throughout the operation time. If the car needs to change layers, most of them are completed by using hoists outside the roadway. After the car automatically drives into the elevator, the elevator is lifted to the required floor, and the floor change is completed. In practical applications, there are two operation modes for hoists: one is working with a car, and the other is working without a car. When working without a car, the elevator only lifts the cargo unit. When working with a car, each time the car and the cargo enter the elevator simultaneously, there is actually no need to change the layer of the elevator. Obviously, when lifting without a car, each layer requires a cargo transfer workstation, which naturally increases the price. However, when working with a car, the system is much simpler, and the end of each layer is also much simpler, but the efficiency is also much lower. This should be noted.

Although the cost and price of the pallet four-way shuttle truck warehouse are much higher than those of ordinary warehouse shelves, the price of the pallet four-way shuttle truck warehouse is relatively low compared to the automated warehouse. In recent years, many enterprises have begun to use automated shelves for their own warehouses. Automated shelves not only improve warehouse storage capacity and efficiency, but also save labor and warehouse operating costs. In the long run, the return on investment is also much higher than that of ordinary warehouse shelves. Every penny, every penny, and pallet four-way shuttle truck three-dimensional warehouse is worth such a high procurement cost.

Post time: Mar-28-2023