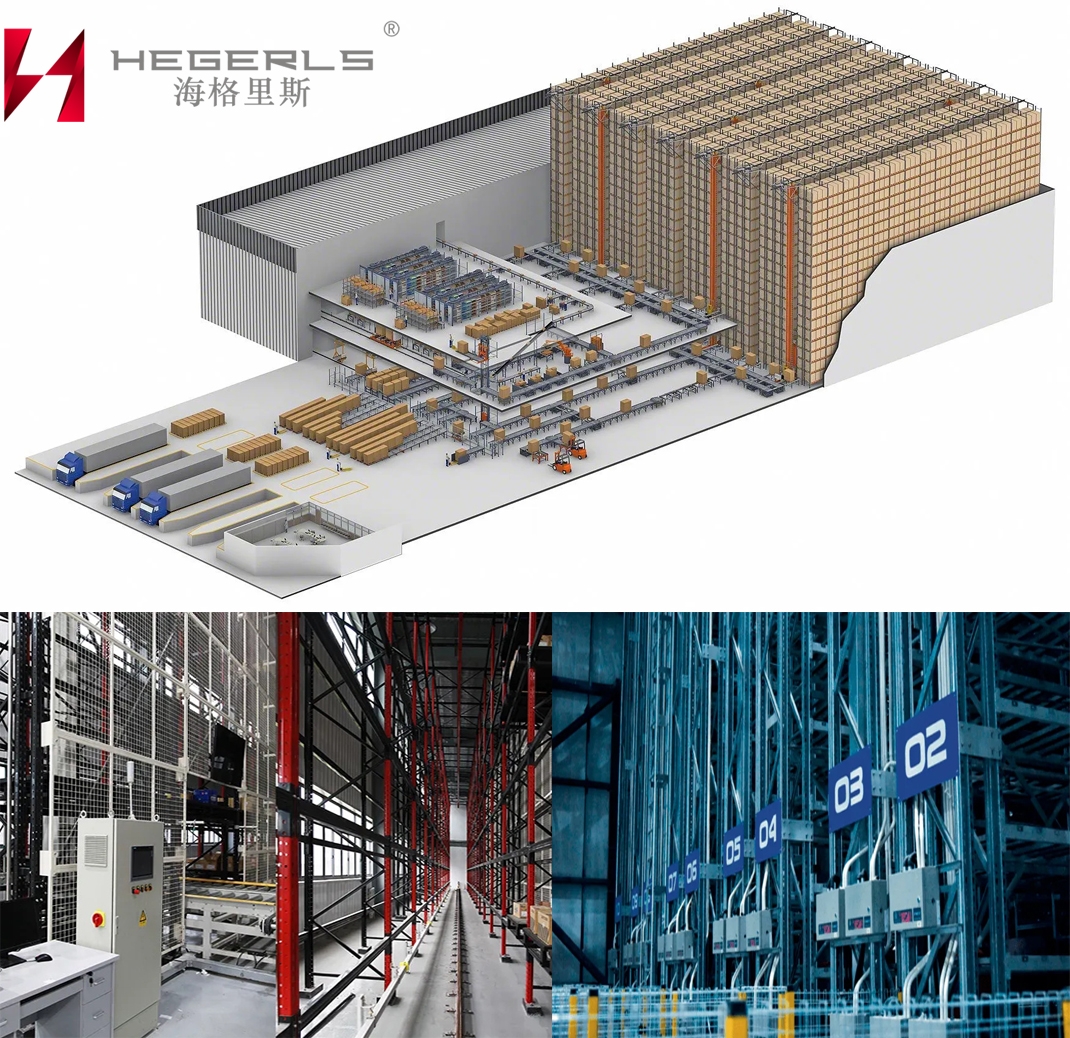

With the continuous development of new technology, in recent years, a new concept vocabulary, automatic three-dimensional library, has appeared in the logistics system. Automatic three-dimensional warehouse (AS-RS) is a new type of modern warehouse which adopts high-rise shelves and track roadway stacker, and cooperates with a variety of peripheral equipment to realize automatic access and cargo management. It realizes the high-level rationalization of three-dimensional warehouse by using automatic storage equipment and computer control and management technology, and forms a complete set of modern three-dimensional warehouse management system by combining different types of warehouse management software, graphic monitoring and scheduling software, bar code identification and tracking system, handling robot, AGV trolley, cargo sorting system, stacker identification system, stacker control system, cargo location detector, etc, At the same time, it will maximize the function of the three-dimensional library and provide enterprises with a complete logistics automation solution from storage, automatic transportation, automatic production to finished product distribution.

You should know that each part of the system composition of AS-RS plays a specific and different role, as follows:

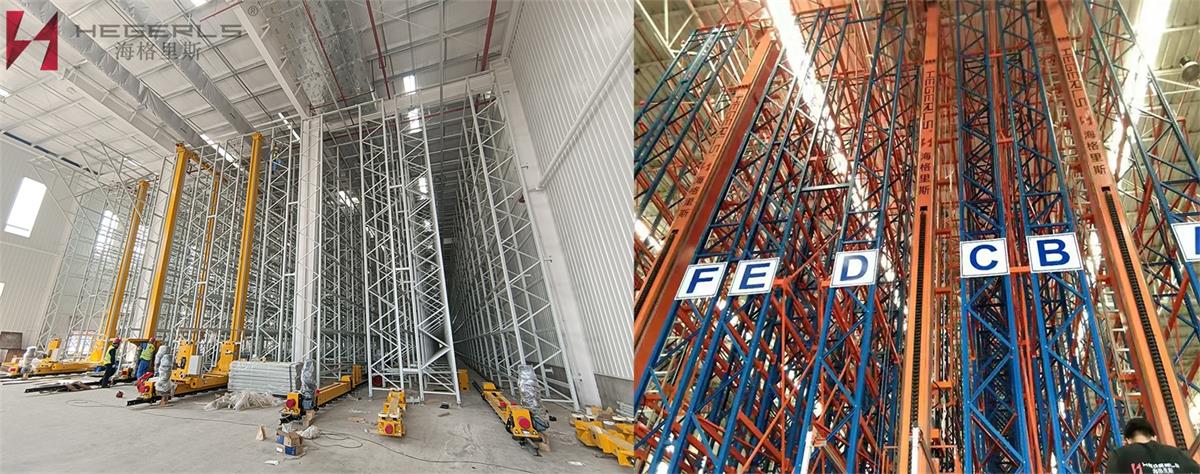

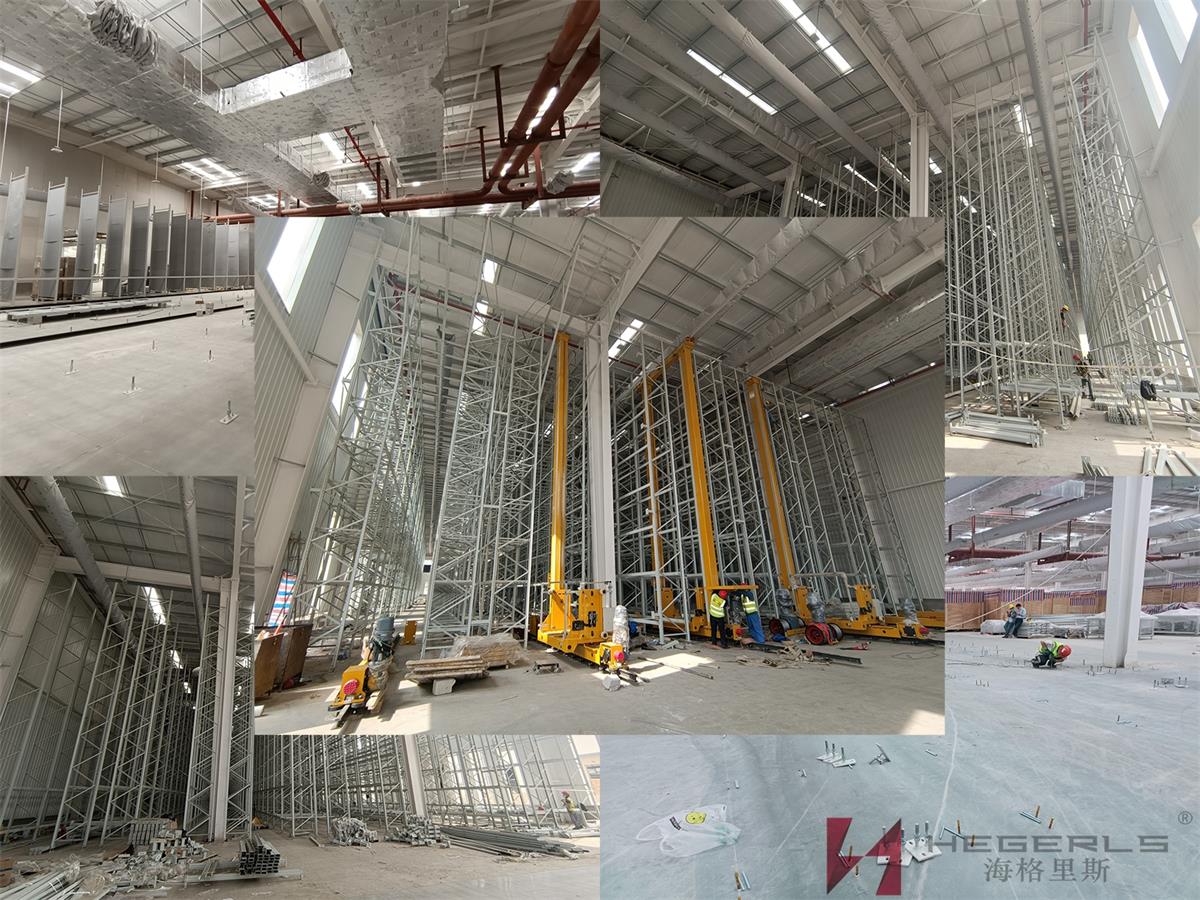

High-rise shelves: high-rise shelves are mainly used to store goods in steel structures. Of course, at present, there are mainly two basic forms: Welded shelf and combined shelf.

Pallet (cargo box): pallet is mainly used for carrying goods, so it is also called station instrument.

Roadway stacker: it is used for automatic access to goods. According to its structural form, it can be divided into two basic forms: single column and double column; According to its service mode, it can be divided into three basic forms: straight road, curve and transfer vehicle.

Conveyor system: the conveyor system is the main peripheral equipment of the three-dimensional warehouse, which is responsible for transporting goods to or from the stacker. Of course, with regard to the conveyor system, Hebei hegris hegerls storage shelf manufacturer is exclusively customized. It mainly produces a wide variety of conveyor equipment, such as rail conveyor, chain conveyor, lifting table, distribution car, elevator and belt conveyor. In addition, hegris also produces and manufactures other storage equipment, namely forklift, pallet, container, stacker, etc., which are qualified by professional institutions, Professional production, professional manufacturing.

AGV system: that is, automatic guiding car, which is divided into inductive guiding car and laser guiding car according to its guiding mode.

Automatic control system: it is an automatic control system that drives all equipment of the automatic three-dimensional warehouse system. According to the current operation, the fieldbus mode is mainly used as the control mode.

Inventory information management system (WMS): also known as computer management system. It is the core of the fully automated three-dimensional library system. At present, the typical automatic three-dimensional database system adopts large-scale database system (such as Oracle, Sybase, etc.) to build a typical client / server system, which can be networked or integrated with other systems (such as ERP system, etc.).

Of course, the reason why AS-RS is put into use by more and more enterprises is also due to its own advantages. Automatic three-dimensional warehouse AS-RS can improve the space utilization rate of enterprise warehouse, reduce the storage land, save the investment cost of land, and form an advanced logistics system to improve the production and management level of enterprises. At the same time, it will also speed up the access rhythm of goods to ensure the improvement of production efficiency. Moreover, AS-RS can also realize the overall optimization of the system, improve the level of production and logistics management, and realize the all-round real-time management of warehouse materials in the allocation process, which not only reduces the labor intensity, improves the working environment of workers, reduces the labor cost, but also reduces the backlog of inventory funds; In this way, a unified asset database is established, which improves the reliable basis for the whole supervision of assets.

In this way, the problem comes with it. The space utilization rate of automated three-dimensional warehouse is 2-5 times that of ordinary flat warehouse. Multiple times of storage capacity makes three-dimensional warehouse one of the popular storage shelf types at present. As enterprise decision-makers, what factors should we consider before planning to invest in three-dimensional warehouse? Next, Hebei haigris hegerls storage shelf manufacturer will conduct a detailed analysis. The preparations required before the design of AS-RS combined with AGV / WCS / stacker are as follows:

1) It is necessary to understand the enterprise’s investment and staffing plans for the storage system, so as to determine the scale of the storage system and the degree of mechanization and automation.

2) Understand the site conditions of the reservoir, including meteorological, topographic, geological conditions, ground bearing capacity, wind and snow load, earthquake and other environmental impacts.

3) Investigate and understand other conditions related to the storage system. For example, the source of Inbound Goods, the traffic conditions connecting the warehouse yard, the number of inbound and outbound doors, packaging form, handling method, the destination of outbound goods and means of transportation, etc.

4) Automated warehouse is a subsystem of the enterprise logistics system. We must understand the requirements of the whole logistics system for the subsystem and the layout of the overall design of the logistics system, so as to carry out the overall design of the storage subsystem. Investigate the types, quantities and laws of goods in and out of the warehouse or stockyard in the past, so as to predict the future and calculate and analyze the warehouse capacity.

5) Automated warehouse is a multi-disciplinary project of machinery, structure, electrical and civil engineering. These disciplines intersect and restrict each other in the overall design of the warehouse. Therefore, consideration must be given to all disciplines in the design. For example, the motion accuracy of machinery should be selected according to the structural manufacturing accuracy and the settlement accuracy of civil engineering.

6) Investigate the product name, characteristics (such as fragile, fear of light, fear of moisture, etc.), shape and size, single piece weight, average inventory, maximum inventory, daily incoming and outgoing quantity, warehousing and outgoing frequency, etc. of the goods stored in the warehouse.

The above are the specific issues that the enterprise should consider before deciding to invest in the automatic three-dimensional warehouse, including some professional issues. You can specifically communicate with the warehouse shelf provider (such as hebeihai Gris herls storage shelf manufacturer), request the other party to analyze and investigate the effectiveness of the project, and finally confirm whether the project scheme is feasible to avoid ineffective work.

Post time: May-11-2022