The warehousing and logistics industry has stepped into the era of automated system integration. The equipment with storage shelves as the storage subject has gradually developed into the storage mode of automated logistics system. The working subject has also changed from shelf storage to robot+shelf, forming a system integrated logistics storage system. As a storage system integrated with shelf+shuttle+elevator+picking system+control software+warehouse management software, The box type four-way shuttle has become an important carrier (unit bin cargo+light four-way shuttle) for lane changing operation and cargo storage, and the application of the box type four-way shuttle has been widely used for various storage integration. With the use of the box type four-way shuttle, it has also become the mainstream equipment at home and abroad.

In the face of the four-way shuttle picking technology, how can enterprises choose more appropriate solutions based on their own needs. Hebei Walker Metal Products Co., Ltd. (self owned brand: HEGERLS) has provided a four-way shuttle car equipment more suitable for large, medium and small enterprises in order to help the purchase decision makers of large enterprises to avoid detours in the selection of the scheme of “goods to people” technology.

About Hebei Walker Metal Products Co., Ltd. (independent brand: HEGERLS)

Hebei Walker Metal Products Co., Ltd., formerly known as Guangyuan Shelf Factory, was an earlier company engaged in the shelf industry in North China. In 1998, it began to participate in the sales and installation of warehousing and logistics equipment. After more than 20 years of development, it has become a one-stop integrated service provider integrating warehousing and logistics project design, equipment and facilities production, sales, integration, installation, commissioning, warehouse management personnel training, after-sales service, etc!

It also established its own brand “HEGERLS”, established production bases in Shijiazhuang and Xingtai, and sales branches in Bangkok, Thailand, Kunshan, Jiangsu and Shenyang. It has a production and research and development base of 60000 m2, 48 world advanced production lines, more than 300 people in R&D, production, sales, installation and after-sales service, including nearly 60 people with senior technicians and senior engineers. The products and services of HGRIS cover nearly 30 provinces, cities and autonomous regions in China. The products are exported to Europe, America, the Middle East, Latin America, Southeast Asia and other countries and regions, and have made remarkable achievements overseas.

Products of HEGERLS:

Storage shelf: shuttle shelf, cross beam shelf, four-way shuttle car shelf, pallet four-way shuttle car shelf, medium shelf, light shelf, pallet shelf, rotary shelf, through shelf, stereoscopic warehouse shelf, attic shelf, floor shelf, cantilever shelf, mobile shelf, fluent shelf, drive in shelf, gravity shelf, high storage shelf, press in shelf, pick out shelf Narrow aisle type shelf, heavy pallet shelf, shelf type shelf, drawer type shelf, bracket type shelf, multi-layer attic type shelf, stacking type shelf, three-dimensional high level shelf, universal angle steel shelf, corridor type shelf, mold shelf, dense cabinet, steel platform, anti-corrosion shelf, etc.

Storage equipment: steel structure platform, steel pallet, steel material box, smart solid frame, storage cage, isolation net, elevator, hydraulic pressure, shuttle car, two-way shuttle car, parent shuttle car, four-way shuttle car, multi-layer shuttle car, stacker, screen partition, climbing car, intelligent transportation and sorting equipment, pallet, electric forklift, container, turnover box, AGV, etc.

New intelligent robot series: Kubao robot series, which includes: carton picking robot HEGERLS A42N, lifting picking robot HEGERLS A3, double depth bin robot HEGERLS A42D, telescopic lifting bin robot HEGERLS A42T, laser SLAM multi-layer bin robot HEGERLS A42 SLAM, multi-layer bin robot HEGERLS A42, dynamic width adjusting bin robot HEGERLS A42-FW, intelligent management platform, workstation Smart Charge Point.

Automated stereoscopic warehouse: shuttle stereoscopic warehouse, beam stereoscopic warehouse, pallet stereoscopic warehouse, heavy shelf stereoscopic warehouse, automated warehouse stereoscopic warehouse, attic stereoscopic warehouse, layer stereoscopic warehouse, four-way shuttle car stereoscopic warehouse, mobile stereoscopic warehouse, narrow roadway stereoscopic warehouse, unit stereoscopic warehouse, through stereoscopic warehouse, cargo format stereoscopic warehouse, automated cabinet stereoscopic warehouse, strip shelf stereoscopic warehouse, picking stereoscopic warehouse, semi-automatic stereoscopic warehouse Linear guideway stereo warehouse, U-guideway stereo warehouse, traverse guideway stereo warehouse, low floor stereo warehouse, middle floor stereo warehouse, high floor stereo warehouse, integrated stereo warehouse, layered stereo warehouse, stacker stereo warehouse, circulating shelf stereo warehouse, etc.

Warehouse management system: order management system (OMS), warehouse management system (WMS), warehouse control system (WCS) and transportation management system (TMS). The warehouse management system provided by HEGERLS can promote the efficiency improvement and cost reduction of the whole chain, and realize the real “intelligent warehouse configuration integration”.

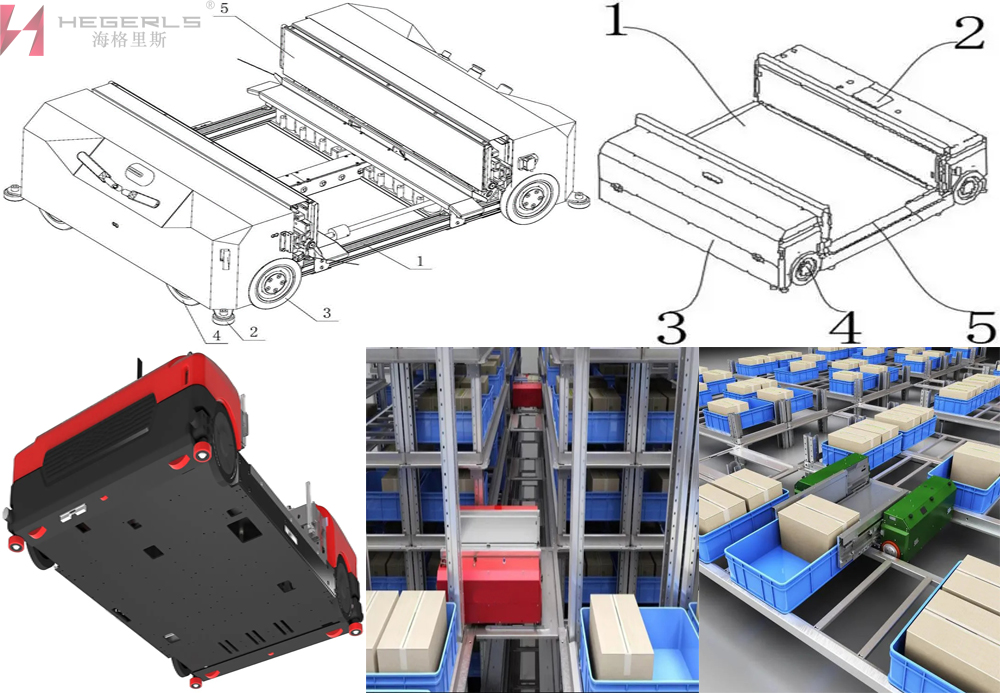

About the box type four-way shuttle

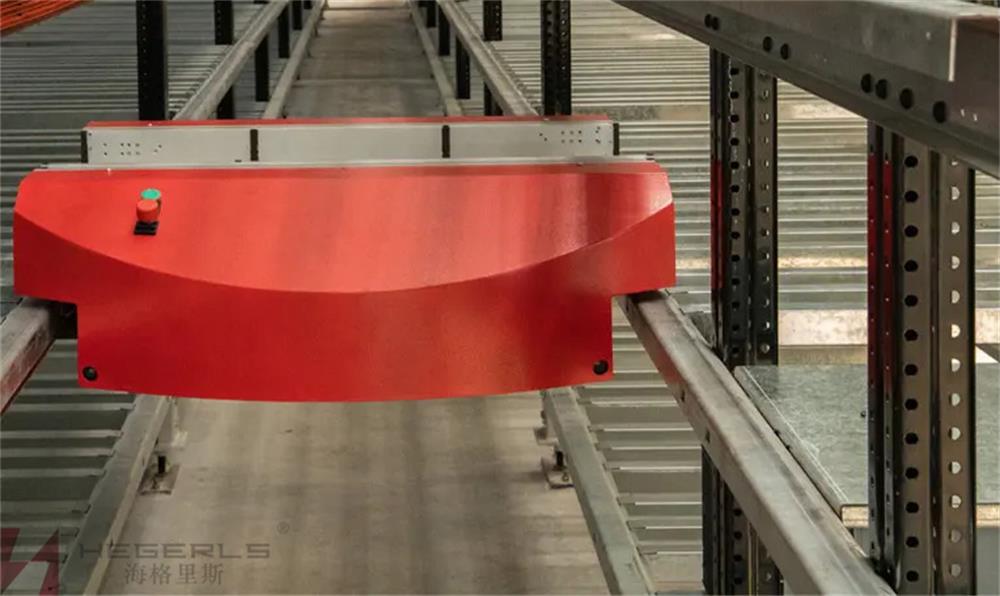

Compared with the traditional automatic handling equipment, the four-way shuttle can reduce the energy consumption and handling cost by reducing the weight of the handling equipment. The research and development of HEGERLS box type four-way shuttle makes up for the multi-dimensional movement defects of the current two-way shuttle. It can arbitrarily change the working roadway, and adjust the system capacity by increasing or decreasing the number of shuttle cars. If necessary, it can respond to the peak value of the system by establishing the scheduling mode of the operating fleet, solve the bottleneck of warehouse entry and exit operations, and improve the efficiency of warehousing and exit. Among them, the HEGERLS four-way vehicle drive part adopts efficient energy-saving motor, and uses the independently developed energy recovery technology to collect the released energy during the shuttle deceleration process, reuse it, and reduce the shuttle energy consumption.

The bin four-way shuttle car is mainly an intelligent handling device with the bin as the handling unit. It can achieve any storage location to complete the access task through cross roadway and cross layer operations, and flexibly adjust the number of shuttle cars configured in the system to meet the access requirements. The box four-way shuttle has a high application value in the 2C e-commerce, clothing, retail and other industries with multiple categories, high storage and high requirements for sorting.

The bin type four-way shuttle is a more flexible bin access robot. Similar to the pallet type four-way shuttle, it has a wider range of adaptability. It can not only be applied to various warehouse types, but also be flexible to match the actual needs by increasing or decreasing the number of trolleys. Especially in the goods to people picking system, since the trolley can change layers through the elevator, it can actually operate flexibly in three-dimensional space.

Highlights of HEGERLS box type four-way shuttle:

Intelligent four-way shuttle system

According to the current task status and the running status of the four-way shuttle, the task can be globally optimized to maximize the overall efficiency of the four-way shuttle system and meet the use requirements of the enterprise warehousing system with the most economic investment.

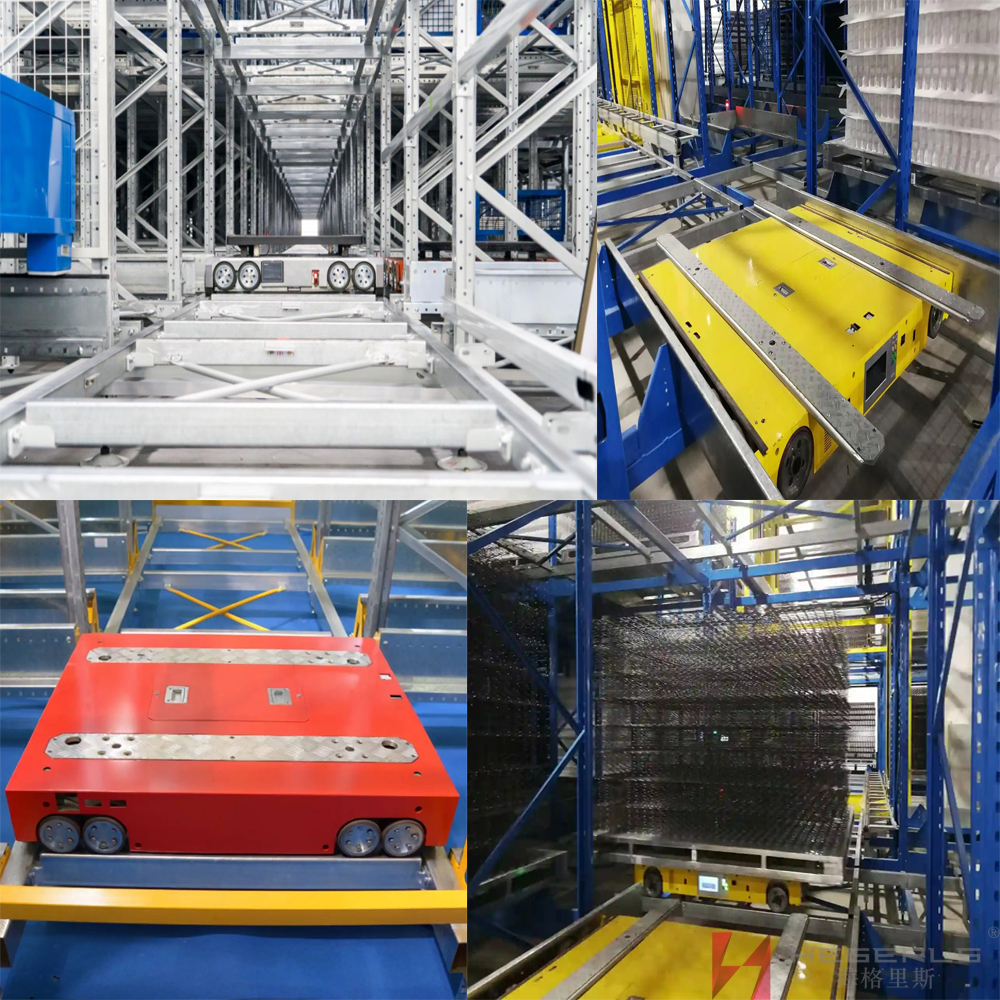

Hoists: There are two typical structures, with car hoist and without car hoist. The car hoist is mainly used for the shuttle car layer change. Sometimes, in order to simplify the system, the car hoist can be used every time, but the operation efficiency is reduced; The hoist without car will have a large lifting capacity. Sometimes, a double station hoist can be used, with a lifting capacity of 250~500 times per hour.

Warehouse layout has multiple options

The box type four-way shuttle car system can be arranged anywhere in the warehouse, which has low requirements for the warehouse and is also suitable for the warehouse with irregular shape;

Flexible, modular and scalable

Through the flexible lane change function, it can meet the cargo handling operation at any position on the same floor, and can work together in multiple units on the same floor to meet the peak input and output operation requirements in the actual use of the project. The system can carry out lean configuration of equipment according to the actual business development needs of users;

Load transfer: relatively speaking, the hopper shuttle is much more flexible. This is mainly because after the unit becomes smaller and lighter, there can be many ways to transfer the load. The simplest way is to use forks. In order to improve the storage density, double depth forks can be used. Sometimes, in order to adapt to cartons with different widths, forks can also be changed in width.

Speed and acceleration: In order to improve the working efficiency, the speed of the trolley will be as high as 5m/s. Because of the clamping device, the acceleration of the trolley can reach 2m/s, which greatly improves the working efficiency of the trolley. For the hoist, the hoisting speed will generally reach 4~6m/s to match the efficiency of the whole system.

Small floor area

Under the same processing capacity, the required channel will be much narrower, reducing the use space and improving the storage area;

Energy saving

Compared with traditional handling equipment, the weight of four-way shuttle is lighter, so it consumes less power to carry goods once. At the same time, the energy recovery technology of the four-way shuttle can recover the energy in the deceleration process, further reducing the energy consumption of the entire handling system;

In recent years, HEGERLS has solved many warehouse storage problems for major enterprises because of its unique four-way shuttle intelligent intensive storage system and unique solutions. As for its HEGERLS intelligent four-way shuttle, it can automatically switch 90 degrees in the longitudinal storage roadway and horizontal transfer channel, so it is more suitable for the warehouse storage mode in those complex terrain environments; Because the individual machines and units of HEGERLS intelligent are connected with each other under the support of wireless network, and under the scheduling of WMS WCS upper management and control system, they can respond to each other to complete the first in first out or first in last out warehousing and outbound of goods.Moreover, HEGERLS intelligent four-way shuttle car intelligent intensive storage system is composed of horizontal conveying system, shelf system, four-way shuttle car, fast vertical elevator and its WMS WCS management and control system. The biggest advantage of such a system lies in its high storage density, stable system operation, high security redundancy, and strong expansion of the inventory efficiency in the later period. At the same time, it has been widely used in e-commerce logistics, refrigeration, textile shoes and clothing, auto parts, hardware and building materials, equipment manufacturing, military supplies and other industries.

Post time: Dec-22-2022