With the rapid development of e-commerce, medical, clothing, books, rail transit, automobile, new retail and other industries, enterprise users’ demand for warehousing and storage is getting higher and higher. For this reason, automated three-dimensional warehouse shows a stronger life and adaptability. The case of Hebei Walker Metal Products Co., Ltd. (self owned brand: HEGERLS) successfully building a fully automated logistics warehousing system is the best proof of the preference of e-commerce logistics and other industries for automated warehouse.

Since its establishment, Hebei Walker Metal Products Co., Ltd. has become a one-stop integrated service provider integrating warehousing and logistics project scheme design, equipment and facilities production, sales, integration, installation, commissioning, warehouse management personnel training, after-sales service, etc. through more than 20 years of development! It also established its own brand “HEGERLS”, established production bases in Shijiazhuang and Xingtai, and sales branches in Bangkok, Thailand, Kunshan, Jiangsu and Shenyang. It has a production and research and development base of 60000 m2, 48 world advanced production lines, more than 300 people in R&D, production, sales, installation and after-sales service, including nearly 60 people with senior technicians and senior engineers.

Self owned brand HEGERLS has developed a variety of storage shelves, storage equipment, new robots, system software and other models. As far as shuttle models are concerned, there are single/double deep shuttle cars, clip on telescopic fork shuttle cars, anti-static shuttle cars, etc. The new generation of storage robots from high-end accessories such as design, R&D, production and manufacturing of these shuttle cars can meet the operation needs of different special industries. Today, the shuttle car most used by large, small and medium-sized enterprises is the clip on four-way shuttle car.

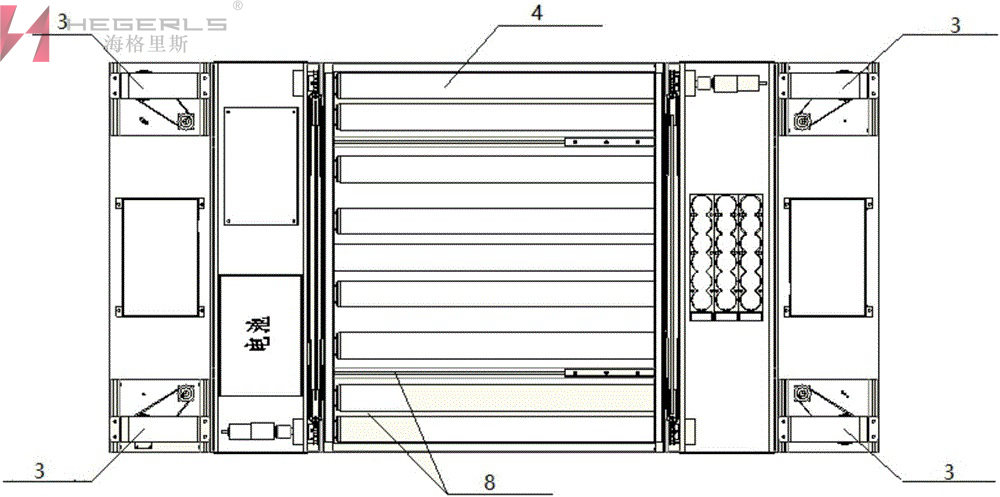

Higelis HEGERLS clip on four-way shuttle intelligent stereo library

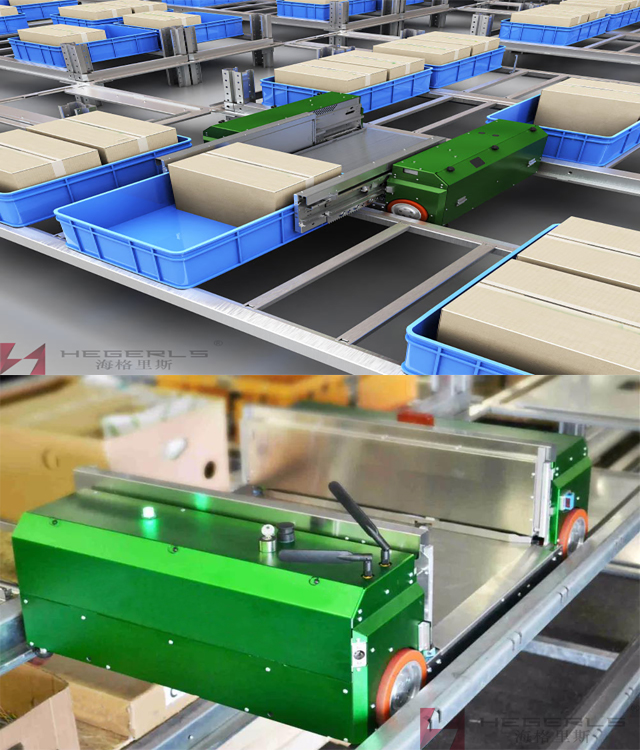

The gripping four-way shuttle provided by HEGERLS is a storage intelligent shuttle robot with simple structure, light weight, safety and reliability. Its biggest feature is that it can accurately locate at all levels of the automated warehouse, flexibly access the cargo baskets on different storage locations, and give full play to its use efficiency to ensure the stability and reliability of the gripping four-way shuttle. The intelligent stereo warehouse of the gripped four-way shuttle mainly stores materials in boxes. At the same time, the gripped four-way shuttle can quickly adjust the clamping spacing, clamping height and clamping position, so that the gripped four-way shuttle can clamp cargo boxes of different sizes, which not only simplifies the complexity of the cargo access process in the intelligent stereo warehouse, but also reduces the economic cost.

The HEGERLS clip on four-way shuttle is suitable for various scenarios with different cargo sizes and specifications.

❑ Automatic access operation can be realized

❑ The picking mode is picking goods to people order

❑ The stacking method is mixed box stacking

❑ The cache mode is order integration cache

The HEGERLS clip on four-way shuttle has super capacitor technology

❑ Three MIU for 10S operation and driving of clip on four-way vehicle

❑ The clamping four-way vehicle can be charged and discharged repeatedly for 1 million times

❑ Storage of braking energy to realize energy recovery

❑ The capacitor is light, fast, durable and durable

The HEGERLS clip on four-way shuttle can operate with high accuracy and efficiency, speeding up the warehousing

❑ The maximum cargo weight that can be achieved by the clip on four-way shuttle: 50KG

❑ The maximum no-load straight speed that can be achieved by the gripper four-way shuttle: 5M/S

❑ The maximum straight acceleration that can be achieved by the gripper four-way shuttle: 2M/s ²

❑ The maximum operating straight speed of the gripper four-way shuttle: 4M/S

❑ High precision photoelectricity is adopted for the clamping four-way vehicle to detect the positioning point

The HEGERLS clip on four-way shuttle gives great flexibility and diversity

❑ The four way shuttle car can travel in four directions, shuttle in three dimensions, and work across roadways;

❑ The four way shuttle car can also be used as backup between equipment to avoid failure;

❑ The system of the gripper four-way shuttle is intelligent dispatching, and the optimal path is preset;

The GIS system automatically balances the task amount of each unit to ensure that the operation capacity is fully utilized.

In the future, HEGERLS will continue to innovate the shuttle bus, show its features of richer functions, more comprehensive performance and more powerful systems to enterprise users, and provide more diversified intelligent warehousing solutions for more warehousing fields and other logistics industries with highly standardized services and rich experience in intelligent warehousing!

Post time: Dec-28-2022