Shuttle shelf is not only a kind of intelligent shelf, but also a commonly used shelf type in intelligent shelves at present. It is also a high-end three-dimensional storage device. It is favored by many enterprises because of its advantages of saving manual operation costs, high storage density, large storage capacity, and realizing warehousing automation. It is precisely because of its own characteristics and audience situation that it has gradually derived many types in its future use, including two-way shuttle shelf, child parent shuttle shelf and four-way shuttle shelf. Among them, the four-way shuttle shelf is a recent type, and the other two types appeared earlier than it. Since it is a recent type, it shows that it is closer to the current needs of customers, and it is also a breakthrough in the original two types.

Shuttle shelf wholesale manufacturer

In fact, one or two can be realized from the words. Two way shuttle, that is, shuttle that can travel in two directions, that is, forward or backward. The four-way shuttle, that is, it can travel in four directions, that is, front, back, left and right. It can be seen that there is a big difference between the four-way shuttle shelf and the two-way shuttle shelf. In a deeper understanding, the four-way shuttle shelf will be more flexible to use than the two-way shuttle shelf, because it can travel in the four directions of front, back, left and right, and it is also higher than the two-way shuttle shelf in terms of the efficiency of goods storage and picking, saving the operation cost of all aspects of the warehouse. This is also the reason why many enterprises give priority to the four-way shuttle shelves of the wholesale manufacturers of shuttle shelves.

Hergels storage shelf manufacturer is a storage service company dedicated to the product R & D, design, production, sales and installation services of automated three-dimensional warehouses, storage shelves and storage equipment. Its products include automated three-dimensional warehouses, fully automated intelligent intensive warehouses, stacker three-dimensional warehouses, four-way shuttle car three-dimensional warehouses, child parent shuttle car three-dimensional warehouses, three-dimensional warehouse shelves, shuttle shelves High shelf, steel structure attic platform, steel attic shelf, storage shelf, medium shelf, heavy shelf, beam shelf, corridor shelf, fluent shelf, cantilever shelf, logistics handling equipment, modular containers, tool storage equipment, workshop station equipment, workshop isolation equipment, aerial work equipment, intelligent storage system, WMS storage management system, WCS warehouse control system, system integration, etc. Hagris’ products and services cover nearly 30 provinces and autonomous regions in China. Its products are exported to Europe, America, the Middle East, Latin America, Southeast Asia and other countries and regions, and have made remarkable achievements overseas. Next, let’s take a look at the four-way shuttle rack automated three-dimensional library produced and manufactured by haggis herls.

Hagerls – four way shuttle rack automatic three-dimensional warehouse

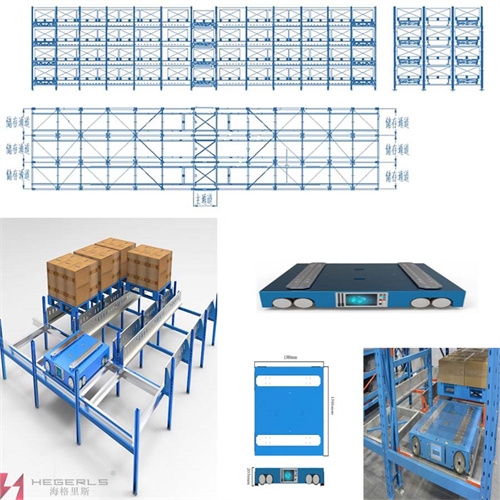

Four way shuttle rack three-dimensional warehouse, that is, multi-layer pallet four-way shuttle high-level shelves, in and out tray automatic conveyor system (including various conveyors, AGV docking support, etc.), pallet cargo overall dimension detection, bar code reading system, automatic picking and sorting system or other automatic control systems, automatic identification system, communication system, computer monitoring and control system Computer warehouse management system (WMS) and other complex systems composed of logistics equipment and auxiliary equipment such as wire and cable tray and distribution cabinet, tray four-way shuttle car and tray unit system, loading rack and adjustment platform, steel structure platform, forklift truck, etc., to realize efficient and intensive storage operation of unit tray goods, which is divided into two main forms: semi-automatic and fully automatic operation, Among them, the manual handling and storage equipment such as forklift is used to store the goods units outside the steel shelf storage area, and the incoming and outgoing goods units are temporarily stored on the exchange location at the operating end of the shelf location (such as the material rack, the first storage location where the shelf can be manually operated or forklift operation, etc.), and then the incoming and outgoing goods are exchanged through the pallet four-way shuttle car The storage and handling in the warehouse floor plane or the layer changing operation between the warehouse floors can be realized in combination with the cargo elevator. The warehouse floor can exist independently in blocks or be connected through the track corridor. The whole storage operation form is semi-automatic mode, and the complete automatic and intelligent continuous warehousing and warehousing operation cannot be built through the peripheral equipment of the warehouse, such as the conveying line.

Hagerls – principle of four-way shuttle rack automatic three-dimensional warehouse

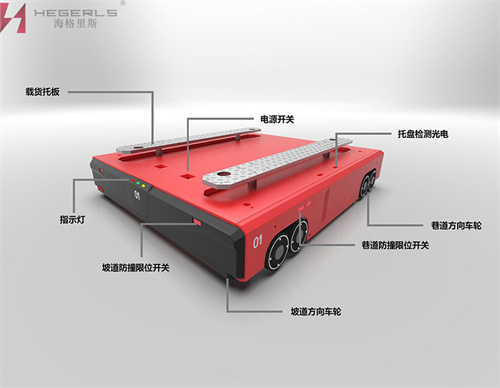

The four-way shuttle shelf uses the vertical and horizontal movement of the four-way car to cooperate with the layer transfer of the elevator to achieve the purpose of storage automation. The four-way vehicle, also known as the four-way shuttle vehicle, can move horizontally and vertically along the scheduled track load, so as to realize the storage and retrieval of goods to the storage location of the shelf. The equipment can realize automatic cargo storage and retrieval, automatic lane change and layer change, and automatic slope climbing. It can also be transported and driven on the ground. It is the latest generation of intelligent handling equipment integrating automatic stacking, automatic handling, unmanned guidance and other functions. The four-way shuttle car has high flexibility. It can change the working roadway at will, and adjust the system capacity by increasing or decreasing the number of shuttle cars. If necessary, it can adjust the peak value of the system and solve the bottleneck of entry and exit operations by establishing the scheduling mode of working fleet. The four-way car is developed from the traditional shuttle car. The general shuttle car can only move in a straight line, so it is generally not used to build a fully automated warehouse, but to cooperate with the forklift for semi-automatic operation. The four-way car, which can shuttle in four directions on one plane, is a kind of equipment widely used in automated warehousing at present.

Four way shuttle cars can be replaced with each other. When a shuttle car or hoist fails, other shuttle cars or hoists can be dispatched through the dispatching system to continue to complete the operation, and the system capacity will not be affected. In terms of the overall cost of the system, the four-way shuttle system also has great advantages. Because the cost of ordinary multi-layer shuttle car or stacker system is closely related to the number of lanes, under the condition of increasing the order volume and not increasing the inventory, each additional lane of these systems will increase the corresponding cost, while the four-way shuttle car system only needs to increase the number of shuttle cars, and the overall cost is lower.

Hagerls – features of four-way shuttle rack automated three-dimensional warehouse

(1) Anti foreign body collision design, each roadway can be flexibly configured with the number of storage layers, which can store a large number of different kinds of items;

(2) The anti-collision design of multi vehicle operation uses multi-layer technology to expand to meet the requirements of customers and realize the high dynamic picking function of goods to people;

(3) The laser positioning protection system, which does not need anti-collision signs on the track, can be driven on the shelf track or on the ground, is not limited by the site, road and slope, and fully reflects its automation and flexibility;

(4) Design to reduce vicious work errors, automatically store and store goods, automatically change lanes and layers, intelligently level and automatically climb slopes, and directly reach any position in the warehouse;

(5) Storage double cycle operation design, in a processing cycle operation, four units can be transported at the same time, and the operation efficiency is very high;

(6) Equipment and facilities, equipped with separate lifting and conveyor for the shuttle, which can be sorted without additional buffer warehouse;

(7) Automatic alarm setting for insufficient battery power. When the battery power is insufficient, stop at the inlet and wait for processing;

(8) It is an intelligent handling equipment integrating automatic handling, unmanned guidance, intelligent control and other functions.

Hagerls – advantages of four-way shuttle rack automated three-dimensional warehouse

(1) Improve efficiency: the four-way shuttle shelf does not need a forklift to enter the shelf, which has high efficiency of goods in and out, and significantly reduces the labor cost of the warehouse;

(2) Free access: goods are first in, first out, first in, then out, which can be freely selected; Four way driving, fast speed and accurate positioning;

(3) Multi vehicle operation on the same floor, intelligent scheduling: facilitate the inventory of goods, and reasonably control the inventory range;

(4) High stability: compared with the drive in shelf, it can achieve the same dense storage, while the seismic safety is much higher than the drive in shelf; It also has the characteristics of strong expansibility and high flexibility; It also has two modes: single extension and double extension;

(5) Unlimited environment: the four-way shuttle shelf warehouse also has the biggest advantage that it can work in the extremely cold environment where manual work cannot work, and the temperature can work normally at minus 25 degrees Celsius, which also provides favorable conditions for some goods that need to be stored in extremely cold conditions.

When designing the four-way automatic goods shelf system, it can be designed into a dense storage mode similar to the shuttle shelf, which is used in an environment with few varieties and large storage volume, or it can be designed into a storage mode similar to the heavy-duty shelf. Each cargo space can be stored and retrieved at any time, which depends on the design number of operation channels.

Hagerls – four-way shuttle rack automatic three-dimensional warehouse application occasions

(1) Each lane stores goods of the same type;

(2) Warehouses where the height of forklifts is limited by the height of shelves;

(3) Warehouse for goods entering and leaving at both ends or one end (first in first out or first in first out);

(4) From the current logistics warehousing mode, it is widely used in medicine, food, tobacco and other industries.

So what are the requirements of the four-way shuttle rack automated three-dimensional warehouse for the space area of the warehouse?

Generally speaking, the larger the warehouse is, the more cost-effective it is to customize the four-way shuttle shelf. The shuttle shelf is basically composed of two parts: storage shelf and shuttle car. The shelf part is similar to the through shelf, which is a kind of dense storage equipment. In fact, the area requirement of the shuttle shelf for the warehouse is not very strict. It can be used from hundreds of square meters to tens of thousands of square meters. However, based on the automatic operation mode, the larger the warehouse, the better. The four-way shuttle rack is operated mechanically throughout the whole process, and there is enough space to ensure the work efficiency and efficient operation of relevant equipment. It is more in logistics warehouses, special material reserves and large cold storage, and these warehouses are generally large in area. If all warehouses want to use shuttle storage shelves, the available area of the warehouse is recommended to be 500 square meters or more in order to achieve the desired output effect. Some customers will be surprised to see the quotation, which is much more expensive than ordinary shelves. In fact, the two cannot be easily compared, and their composition, operation mode and effect are different.

Post time: Jul-26-2022