The main operation areas of the automated three-dimensional warehouse are the receiving area, receiving area, picking area and delivery area. After receiving the delivery note and goods from the supplier, the warehouse center will accept the newly entered goods through the barcode scanner in the receiving area. After confirming that the delivery note is consistent with the goods, the goods will be further processed. Part of the goods are directly put into the delivery area, which belongs to the through type goods; The other part of the goods belong to storage type goods, which need to be warehoused, that is, they enter the picking area. The picking is automatically completed by the automatic sorting and conveying system and the automatic guide system. After sorting, the goods enter the automatic three-dimensional warehouse. When the goods need to be delivered, according to the display on the delivery note, the goods will be sent to the corresponding loading line through the automatic sorting and conveying equipment. After the goods are packaged, they will be loaded and delivered. Then how to configure the operation of the automated three-dimensional warehouse? Now let’s follow the hegerls warehouse to see!

In general, the commonly used equipment required for receiving, warehousing and outbound are as follows:

Receiving operation

The goods will be transported to the designated place by rail or road in containers, and the containers will be unloaded by container operation equipment (including container crane, tire type gantry crane, rail type gantry crane, etc.). Generally, the goods in the container are put on the pallet first, and then the goods are taken out together with the pallet by the forklift for warehousing inspection.

Warehousing operation

After the goods are inspected at the warehouse entrance, they will be placed on the designated pallet according to the instructions issued by the computer management storage system. Generally, forklift, pallet carrier, conveyor and automatic guided carrier are used together to place the goods on the pallet. The conveyor can be belt conveyor or roller conveyor. In general, the conveyor and AGV are controlled by computer.

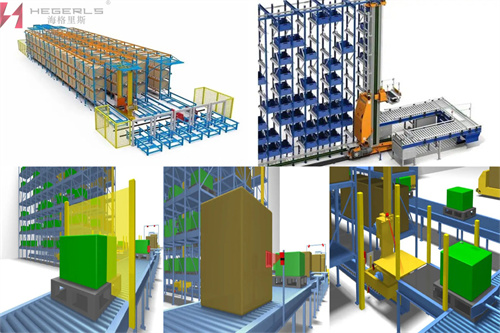

After the goods are placed on the pallet, the laneway stacker will put the goods into the designated rack according to the action instructions, and then the laneway stacker will run longitudinally along the laneway. At the same time, the pallet will rise along the column of the stacker. During the operation and lifting of the laneway stacker, the address information will be continuously fed back to the computer. At the same time, the computer will send various instructions to the laneway stacker to control the operation process of the laneway stacker, Finally, put the goods in the designated position on the shelf.

Here, hegerls also reminds major enterprises that the high-level shelves and stackers in the three-dimensional warehouse are easy to realize standardized products; However, the incoming and outgoing conveyor system shall be specifically planned and designed according to the layout of the warehouse, the content of incoming and outgoing operations, the number of incoming and outgoing stations, and the requirements of diversion and merging. The planning and design of the incoming and outgoing conveyor system is the key to the applicability of the automated three-dimensional warehouse. The planning and design of the incoming and outgoing conveyor system are closely related to the overall dimensions and substructure of the pallet, the loading and unloading methods, automatic control and detection methods of relevant logistics equipment.

Outbound operation

The delivery of goods and the warehouse operation are controlled by the same control system, and the operation process is opposite.

At present, there have been a variety of special working machines, such as incoming and outgoing conveyors, which are an important part of large and complex automated warehouses. They are connected with stackers and other machines to achieve high-speed transport of goods. Although the incoming and outgoing conveyor systems of each user are different, they are still composed of different types of conveyors (chain conveyor, roller conveyor, chain roller table composite conveyor, chain roller table composite conveyor with roller table conveying function) and their basic modules.

Post time: Aug-10-2022