With the steady growth of the overall scale of warehousing and logistics at home and abroad, as well as the demand for low-temperature products, the potential for cold chain market applications is constantly being released. Under the traditional “shelf+forklift” approach, the continuous entry and exit of goods, personnel, and mechanical equipment can easily cause temperature fluctuations, leading to loss of cooling capacity. The three-dimensional cold storage maximizes the utilization of cold storage space in a higher density and more cost-effective way, significantly reducing the impact of incoming and outgoing goods on the storage environment. At the same time, while the construction and operation costs of cold storage remain high, doubling storage capacity has extremely high economic value.

Hebei Woke Metal Products Co., Ltd. (hereinafter referred to as Hebei Woke) is based on the current situation of the cold chain industry, considering the complexity, high cost, and other uncertain factors of cold chain logistics. Based on the “cloud network end” integrated collaborative architecture, a four-way shuttle cold chain warehousing system is developed and designed to technically control and manage risks, forming a complete, efficient, and safe traceable chain. Through platforms such as WMS and Warehouse Brain, combined with technologies such as digital twin, intelligent visualization, and intelligent prediction, effective tracking and real-time insight into the operation status of cold storage operations and cold chain logistics equipment can be achieved, ensuring closed-loop control of the entire process of cold storage operations and traceability of relevant information such as the location, temperature, humidity, specifications, and models of materials.

As a new generation provider of smart logistics products and solutions, Hebei Woke Hegerls Robotics, based on AI native algorithm capabilities and a one-stop platform for robots, continues to create industry benchmark cases, providing efficient and intelligent warehousing and logistics solutions for multiple customers in the food and beverage cold chain. Taking a customer from a certain enterprise in the aquatic cold chain industry as an example, the demand for the HEGERLS four-way shuttle intelligent three-dimensional cold storage project is as follows:

1) -25 ℃ integrated storage rack;

2) The height of the storage rack is 22M;

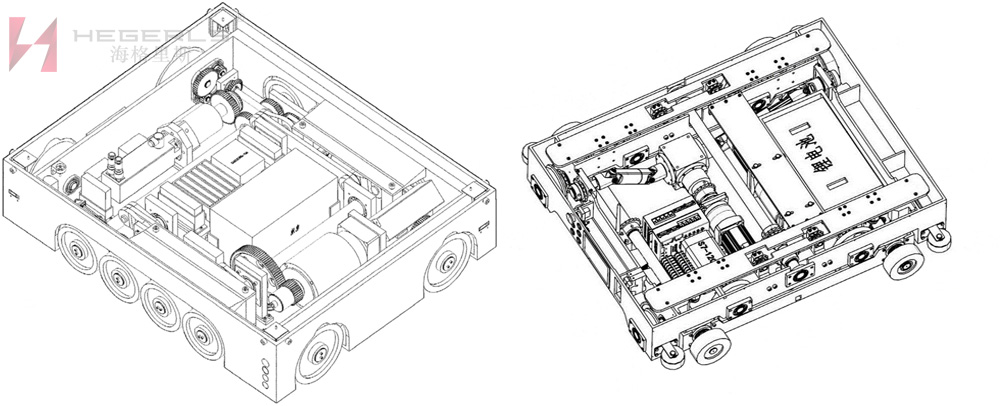

3) Intelligent automated four-way shuttle equipment;

4) Wind resistance level – can be designed according to customer needs.

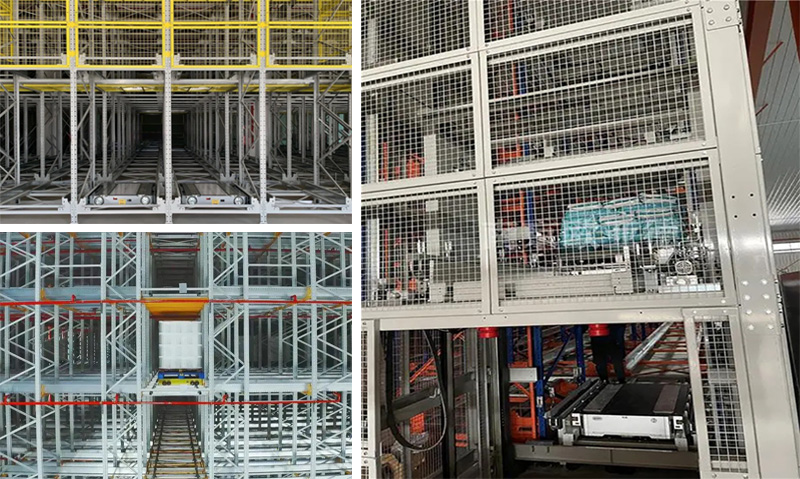

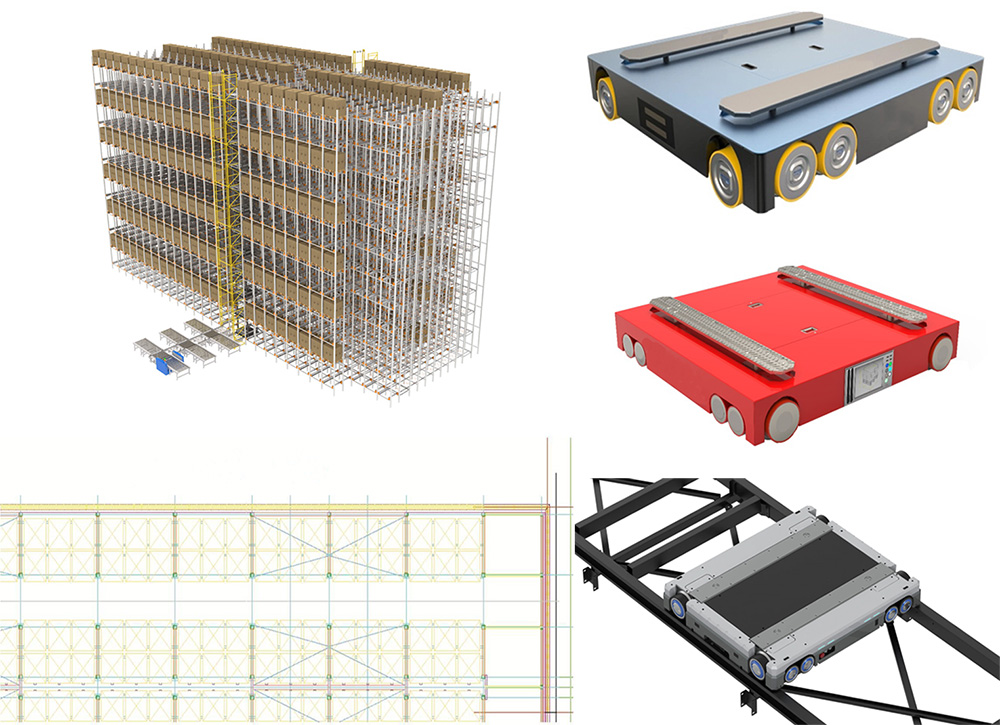

The cold storage environment of the enterprise is -25 °, and a new integrated warehouse with a height of about 22M, namely an intelligent dense three-dimensional warehouse, needs to be built. It needs to be an 8-story intelligent dense warehouse, with a storage capacity of 2416 or more. The main storage materials are pallets (i.e. size: L * W * H is 1200mm * 1000mm; cargo stacking height: below 1800mm, including pallet height).

The project adopts the HEGERLS intelligent four-way shuttle vehicle dense three-dimensional warehouse solution, equipped with multiple HEGERLS cold storage version four-way vehicles, 2 elevators, 24 conveyor line equipment, and 2 sets of top lift transfer machines. Through the warehouse WMS management system and scheduling WCS system, RFID tag management is embedded to achieve intelligent automation of material entry, storage, and exit operations, thereby achieving the requirements of 40 boards/H for entry and 50 boards/H for exit. For ease of use and maintenance, it is also equipped with electronic information display screens, repair channels, and maintenance platforms. The implementation and delivery of cold storage projects are complex, with high requirements for electronic components, batteries, and shelf materials for all equipment such as four-way vehicles and elevators.

The reason why the company chose the HEGERLS intelligent four-way shuttle vehicle storage system is because compared to traditional pallet solutions, the HEGERLS intelligent four-way shuttle vehicle storage system allows the intelligent four-way shuttle vehicle to freely traverse the shelves by adding high-precision rails to the traditional shelves. The guide rail has both cargo transportation and storage functions, greatly improving the utilization of storage space. Due to the fact that all storage and retrieval of goods in automated three-dimensional warehouses are completed by intelligent four-way shuttle trucks, compared to traditional forklift loading and unloading methods, it greatly optimizes labor costs and warehouse space utilization.

Post time: Jan-11-2024