Project Name: Site Inspection and Investigation of Heavy Beam Shelf Project

Project client: Jiangsu Wuxi Technology Co., Ltd

Inspection site: Xingtai production base of Hebei Walker Metal Products Co., Ltd

Factory inspection time: early February 2023

Project customer needs:

In February 2023, Hebei Walker Metal Products Co., Ltd. (independent brand: HEGERLS) received a call from an enterprise in Wuxi, Jiangsu Province, for a detailed consultation on the beam storage intensive shelf. An enterprise in Wuxi, Jiangsu Province mainly focuses on medical equipment. In terms of storage, it wants a beam shelf suitable for its own enterprise warehouse to store its own medical equipment and other products. After the call and negotiation, the two parties are scheduled to come to our factory (Xingtai production base of Hebei Walker Metal Products Co., Ltd.) in the first ten days of February 2023 to inspect the heavy crossbeam type storage dense shelves.

Project overview:

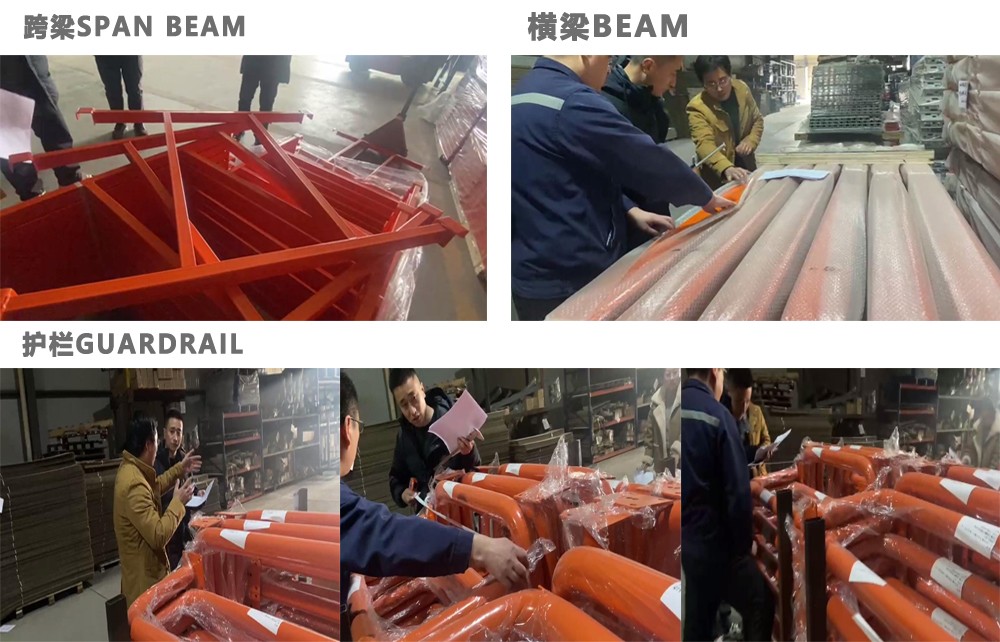

After the person in charge of Wuxi, Jiangsu Province entered our Xingtai base, the manager of our foreign trade department and the relevant person in charge of the factory jointly received and accompanied us to visit various production workshops, such as the spray molding workshop, raw material warehouse, mold workshop, automatic spray molding workshop, and carried out investigation and information exchange work with the person in charge of your company on the production process, processing technology, quality management and other aspects of our factory. During the period, the principals of both parties had a detailed discussion on the heavy beam storage and dense shelves. At the same time, during the investigation, the customers in Wuxi, Jiangsu Province carried out a detailed investigation and measurement of relevant data on the appearance of the rack, the steel structure of the rack, the pallet, the anchor bolt, the guardrail, the span beam, the beam, the fasteners, the anti-collision feet of the column, the shelf components, the verticality of the bottom column, the deflection of the bottom floor beam, the deflection of the bottom floor plate, the load bearing per unit area, the safety bolt, etc, So as to determine the specific requirements of the warehouse of its own enterprise for the crossbeam shelf.

About crossbeam shelf

The crossbeam shelf structure is composed of columns, crossbeams, cross braces and diagonal braces, which are fixed and installed with bolts. Such a structure can make the shelf structure not easy to loosen. The beam has strong bearing capacity and low cost. The safety pin is installed at the position of the crossbeam hanging gear and the column to ensure that the crossbeam can be stable under the impact of external forces, which can greatly meet the first-in, first-out requirements of the food raw material warehouse. It can easily access the goods as long as it cooperates with common forklift types.

The crossbeam shelf is the most widely used shelf, with complete specifications and models, wide bearing range, suitable for all kinds of warehouses, can make full use of space, and use forklift to store and store goods. And use convenient tray access method. It has the characteristics of strong selectivity, first-in, first-out and high inventory turnover. The fully assembled structure in the form of column piece+beam is simple and effective, and functional accessories such as partition, steel laminate (wood laminate), wire mesh layer, storage cage guide rail, oil barrel rack and other functional accessories can be added according to the characteristics of the storage unit container equipment, which can meet the requirements of goods storage in different unit container equipment forms. The floor load requirements of the crossbeam shelf can be determined according to the size of the column and beam specifications. It has the characteristics of large moment of inertia, strong floor load capacity and strong impact resistance. The large floor load of each layer can reach 5000KG/layer under the relative design.

The cost of the beam storage intensive shelf is very low, the installation and operation are very convenient, the location is very fast, and it is suitable for any handling tool, so it is a kind of shelf that is widely used.

Photos of the factory inspection site:

After mutual exchange and understanding on the beam type storage intensive shelves, customers in Wuxi, Jiangsu Province are very satisfied with the high performance and high quality of our beam type storage shelves. After a series of comprehensive reviews of the hardware facilities, operating capacity, quality control process and product delivery capacity of Hebei Walker Metal Products Co., Ltd., and after the end of the investigation and exchange, the customers in Wuxi, Jiangsu Province fully affirmed the factory environment, staff quality, production capacity, equipment level and other aspects of our company, and also highly recognized our production process, production process control and product quality. After the site visit, the two sides also held discussions and exchanges, and reached a consensus on later development cooperation.

Hebei Walker Metal Products Co., Ltd. has been focusing on the R&D and production of storage shelves and storage equipment. After more than 20 years of development, it has become a comprehensive, full-series and full-quality one-stop integrated storage logistics service provider integrating the design of storage logistics projects, production, sales, integration, installation, commissioning, warehouse management personnel training, and after-sales service! It also established its own brand “HEGERLS”, set up its headquarters in Shijiazhuang and Xingtai production bases, and sales branches in Bangkok, Jiangsu Kunshan and Shenyang. Haigris series products and services cover nearly 30 provinces, cities and autonomous regions in China. The products are exported to Europe, America, the Middle East, Latin America, Southeast Asia and other countries and regions, and have made remarkable achievements overseas.

In recent years, the company has stepped up the research and development of automatic storage equipment, and two automatic storage equipment, intelligent shuttle car and intelligent plate warehouse stacker, have won national patents. Relying on these internationally advanced automated storage equipment, Haigris has successively completed the OSCAR automated cold storage project in Chile, the A&A series supermarket project in Mexico, the JM automated storage project in Thailand, the LSP automated storage project in Thailand, the ALLM automated storage project in the United Arab Emirates, and the BIO storage project in Algeria, Among them, the MDF/HDF panel intelligent picking and automatic storage project of South Africa FX Group completed in 2017 is an international leading and original project. We have basically completed the transformation from exporting primary products to exporting complete sets of automation equipment and completing warehousing projects. Since 2018, we have successively completed the large finished product warehouse project of Thailand’s Safin furniture, the large textile turnover warehouse project of Chile’s FS, the electrical three-dimensional warehouse project of Indonesia’s KG intelligent shuttle car, and the automatic three-dimensional warehouse project of Thailand’s A&S car seats.

Of course, in addition to the above automated stereoscopic storage, our company also has a variety of storage shelves for customers. In addition to the production of beam shelves, our company also produces: shuttle shelves, mobile shelves, heavy shelves, light shelves, rotary shelves, stereoscopic storage shelves, loft shelves, floor shelves, cantilever shelves, fluent shelves, drive-in shelves, gravity shelves, steel platforms Anti-corrosion shelves and other storage shelves; In addition, our company also develops, produces and manufactures warehousing equipment: shuttle trucks, forklifts, stackers, sub-carriers, elevators, four-way shuttle cars, intelligent transportation and sorting systems, storage cages, pallets, two-way shuttle cars and other warehousing supporting equipment and facilities.

After more than 20 years of development, Hebei Walker Metal Products Co., Ltd. has always maintained the corporate spirit of quality first and technological innovation, and has continuously improved and improved the cost, management, quality, user satisfaction and performance of development projects. In the same industry, Hebei Walker not only highlights the priority trend, but also shows that the international competitiveness of Hebei Walker is increasingly strengthened.

Post time: Feb-14-2023