Throughout the world, consumer demand is undergoing a transformation, with both individual and corporate consumption showing a trend of personalization, customization, and networking. Therefore, production enterprises are facing new challenges such as product diversification, fragmented orders, and customized services. The demand for intensive storage and large dismantling operations is becoming increasingly evident, and competition pressure is high. With a deep understanding of customer needs, Hebei Woke Metal Products Co., Ltd., as a leading supplier and technical service provider of logistics robot intelligent equipment, has relied on years of product cultivation and technological innovation, Standing out from numerous logistics technology solution providers from the Asia

Pacific region, driven by artificial intelligence technology, we create core products, conduct in-depth research on artificial intelligence algorithms, apply data mining, image processing, intelligent optimization and other technologies to equipment innovation development and logistics scenario applications, expand the application scope and collaborative scale of intelligent logistics equipment systems, and customize various highly intelligent systems that can be mature and applied in the market High end logistics robots and solutions with high flexibility, reliability, and cost-effectiveness.

The R&D concept of Hebei Woke Metal Products Co., Ltd. is to build the Hagrid HEGERLS brand into a standardized, modular, and intelligent equipment cluster, transforming from traditional "dedicated machine" to "one machine with multiple functions", and opening up a scalable, highly stable, and cost-effective logistics system. Hebei Woke Metal Products Co., Ltd. has formed a comprehensive warehousing solution that includes logistics system

consulting planning, software development, equipment manufacturing, and project delivery, including the research and development and manufacturing of core high-end logistics equipment such as HEGERLS four-way shuttle, pallet/box stacker, pallet shuttle, high-speed elevator, AGV&AMR, dismantling/stacking picking robots, transportation and sorting systems, covering medical, semiconductor, new energy, retail, e-commerce, etc Numerous segmented industries such as libraries.

HEGERLS intelligent system scheduling and Kinetic energy recovery system enable products to achieve intelligent avoidance function, which can make the automated logistics system solution highly flexible and quickly adapt to various logistics business needs, so as to alleviate the diversified challenges of enterprise logistics business, and better meet the goal of completely unmanned customers.

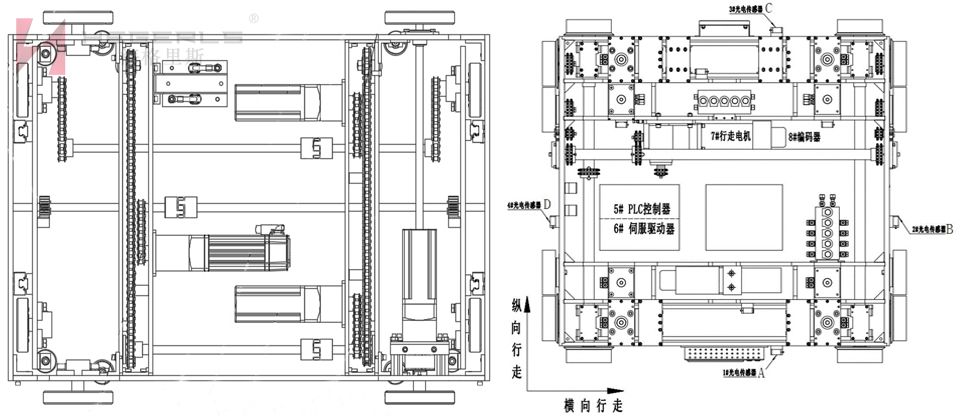

Unlike traditional access devices, the HEGERLS four-way shuttle vehicle proposes an innovative concept of a flat "layer" of vertical storage. The key behind this innovation is the scheduling algorithm, which uses MFC software to assign tasks, coordinate scheduling, control path traffic, and dynamically manage the access system's small cars. It not only perfectly solves the problem of access efficiency, but also flexibly adjusts the operation path and car allocation, solving the bottleneck problem of traditional multi-layer shuttle cars in lifting machines.

How does the HEGERLS four-way shuttle scheduling algorithm solve the problem of vehicle path planning and avoidance when there are multiple vehicles on the same layer?

The concept of "multiple vehicles on the same floor" proposed by HEGERLS breaks the "fixed partition" mode, allowing small cars to cross other areas in need for operation. At the same time, the number of small cars can be flexibly configured, and there is mutual substitutability between cars, making the configuration of small cars more flexible. Within the same layer of shelves, there are avoidance modes for four-way shuttle vehicles in

different scenarios. One is to avoid the intersection of vehicle paths during the initial planning process, and the other is an effective avoidance mode between vehicles when encountering unexpected intersections during the initial planning execution process.

In terms of venue adaptability, the HEGERLS four-way shuttle can move in four directions, greatly increasing its flexibility in adapting to the venue, and making full use of the space in some irregular venues. On the one hand, it can significantly improve space utilization, and on the other hand, in many old warehouse renovations, four-way shuttle cars have higher adaptability. At the same time, in order to avoid the high conflict rate of multi vehicle operations in the same area, which affects efficiency, the HEGERLS four-way shuttle will also change the range of the area based on the real-time distribution of tasks. In the dynamic area, multiple vehicles in one area can reduce interference between vehicles, meet the needs of job allocation, improve the mobility of the vehicles, and achieve a better solution.

Hebei Woke Metal Products Co., Ltd. has always adhered to the concept of "scenario as the king, technology as the foundation", focusing on the three core scenarios of access, handling, and sorting in the logistics field, comprehensively layout the technology research and production of robots and automation equipment products, and strengthen the in-depth application of software products such as WMS, WCS, RCS in the industry. At the planning level, Hebei Woke Metal Products Co., Ltd. deeply understands customer needs, coordinates the overall situation for customers, and provides forward-looking solutions that can meet the future development of the business for many years. At the level of hardware equipment and software development, Hebei Woke has a product cluster spanning the three core scenarios (access, handling and sorting) of the intelligent factory. From hardware such as shuttle cars, stackers and AMR mobile robots to WMS, WCS, MES and the intelligent algorithm optimization and software systems supporting AMR, Hebei Woke has a complete Logistics automation product line.

Post time: Jul-11-2023