Generally speaking, material packaging can be divided into pallets and boxes, but the two have completely different logistics operations within the warehouse. If the cross-section of the tray is large, it is suitable for handling finished products; For smaller material boxes, the main components need to be original and spare parts. Of course, all forms of logistics cannot do without pallets, and factory production cannot do without material boxes. In this regard, the storage equipment used in warehousing logistics can be divided into two types based on the different processing forms: box type shuttle and pallet type shuttle.

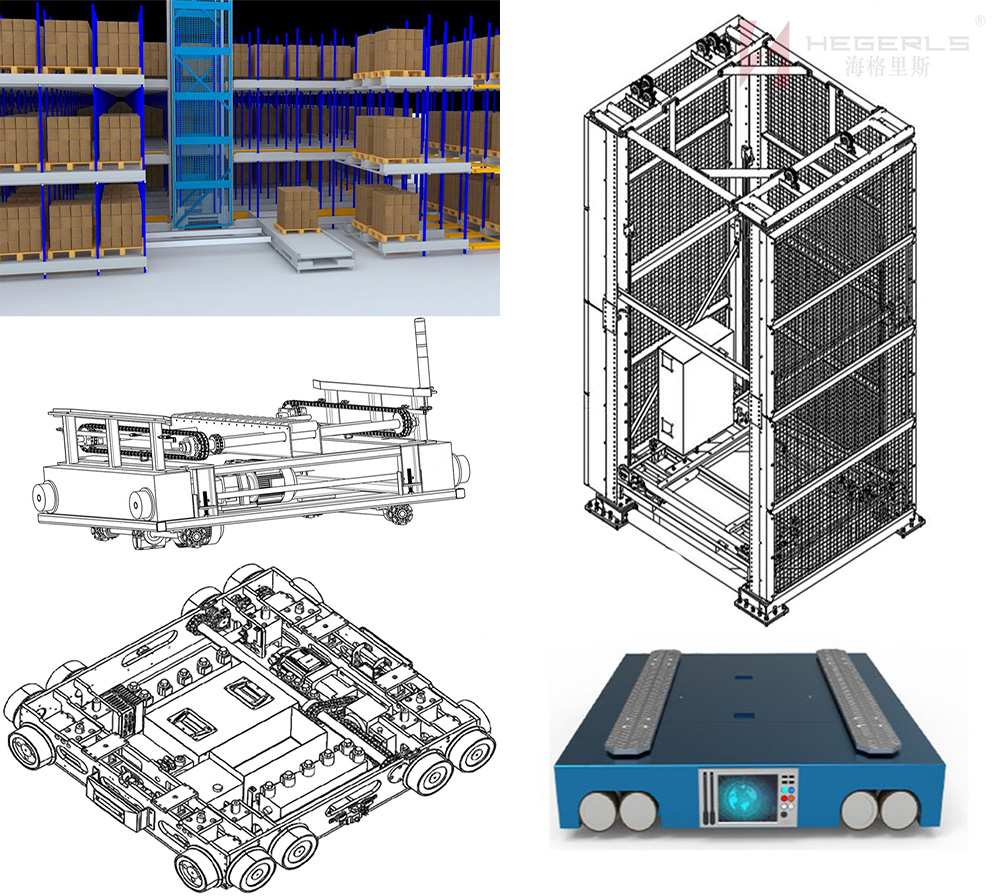

Among them, the tray four-way shuttle system used has high technical barriers, mainly manifested in structural design, positioning and navigation, system scheduling, perception technology, and other aspects. In addition, it will also involve coordination and docking between multiple software and hardware, such as hardware equipment such as layer changing elevators, track conveyor lines, and shelf systems, as well as software such as equipment scheduling control systems WCS/WMS. At the same time, unlike AGV/AMR running on a flat surface, the four-way shuttle truck on pallets walks on three-dimensional shelves. Due to its unique structure, it can also cause many challenges, such as accidents such as pallets, cargo falling, and collisions between vehicles. Therefore, in order to reduce risks and ensure safe operation, the four-way shuttle truck for pallets has undergone stricter requirements in terms of process, positioning accuracy, path planning, and other aspects.

Since its establishment, Hebei Woke has been focusing on the field of warehousing and logistics robots, as well as technology exploration and services. Through the use of computing intelligence, ultra-low latency communication networking and other technologies, it has broken through the bottlenecks of traditional material box stackers, linear shuttle vehicles, etc. in terms of autonomous scheduling, path optimization, system efficiency, space limitations, and has successively promoted shuttle vehicles, two-way shuttle vehicles, four-way shuttle vehicles, stacker cranes, elevators, conveying and sorting Warehouse equipment such as Kubao robots and supporting software systems. In addition to focusing on these warehousing equipment, Hebei Woke has also made breakthroughs in the efficiency of material box and pallet handling in recent years. With the integration of AI intelligent algorithm scheduling systems, it has developed high-performance and highly reliable HEGERLS pallet four-way shuttle robots, which can truly help enterprise customers solve difficulties in access, handling, picking, and other aspects. As an important logistics and warehousing equipment under the independent brand of Hebei Woke, HEGERLS pallet four-way shuttle has participated in more logistics application scenarios, providing efficient and flexible warehousing solutions for more cooperative customers.

The HEGERLS (Pallet Four Way Shuttle) is deeply integrated with the Hagrid WMS and WCS systems, and can be used in conjunction with the “goods to people” picking workstation, conveyor line, and elevator to achieve an intelligent warehousing solution for “goods to people”. It can also be perfectly integrated with the logistics information management system to achieve functions such as automated identification, access, handling, and picking. Thanks to its excellent sorting function, the HEGERLS pallet four-way shuttle also adopts a multi-level path control system to plan reasonable paths and transport goods in an orderly manner to the manual picking table, completing orders quickly and accurately and delivering them in a timely manner. With the assistance of the HEGERLS scheduling system, the operational and management efficiency of many users in various fields has been greatly improved, reducing management risks. The digitalization of the warehouse management system enables the user end system to trace the entire chain of items, optimize the inbound and outbound processes, achieve true automation management, and accelerate the digitalization process of user enterprises in warehousing!

Due to its many outstanding advantages in improving storage efficiency and warehouse space utilization, it is increasingly favored by the market and has been widely used in various industries such as medical, retail, and e-commerce with high storage and dismantling needs. At the same time, it is also applicable in intelligent manufacturing logistics fields with high added value and industrial automation, such as automotive manufacturing, 3C manufacturing, new energy, and semiconductors.

The birth of the four-way shuttle provides a highly effective warehousing solution for dense storage and rapid sorting, and is a major innovation in logistics equipment technology. Meanwhile, the flexibility and scalability of the HEGERLS tray four-way shuttle system ensure the stability and sustainability of project use; At the same time, Hebei Woke relies on its strong planning and design, software development, and integration implementation capabilities to create customized and specialized logistics centers according to the different needs of users.

Post time: Jan-24-2024