In recent years, the storage land is becoming more and more tense, the storage location is insufficient, the human cost is increasing, and the problem of difficult employment is becoming increasingly prominent. Coupled with the increase of the enterprise’s own variety of materials, the traditional storage mode has been difficult to meet the development needs of enterprises. In this case, pallet solutions based on intelligent pallet four-way shuttle cars began to emerge in intelligent warehousing. Now, the solution of intelligent pallet four-way shuttle is widely used in the market. The intelligent pallet four-way shuttle car can be used in irregular and special-shaped warehouses, warehouses with large length and width, warehouses with high or small warehousing efficiency, or warehouses with small varieties and large batches, and warehouses with many varieties and large batches. It has high flexibility and is suitable for high density shelves. It can realize any shuttle. It can be flexibly adjusted according to the investment plan. Combined with a special elevator, it can realize the goods layer change.

The intelligent pallet four-way shuttle car is an intelligent robot, which can be programmed to carry out the operations of picking, transporting and placing goods on the three-dimensional warehouse, and can communicate with the upper computer or WMS system. Combined with RFID, bar code identification and other logistics information technology, it can realize the functions of automatic identification, single access, continuous access, automatic tally and so on. The intelligent pallet four-way shuttle storage system enables the intelligent pallet four-way shuttle to travel freely through the shelves by adding high-precision guide rails to the traditional shelves. The guide rail has the functions of goods transportation and goods storage, which greatly improves the utilization rate of storage space. As the storage and retrieval of goods in the automated three-dimensional warehouse are all completed by the intelligent four-way shuttle car, compared with the traditional forklift loading and unloading method, it greatly optimizes the labor cost and warehouse space utilization. The intelligent four-way shuttle car is a handling machine that continuously transports goods on a certain line. The intelligent four-way shuttle has strong transportation capacity and can carry large loads; The conveying speed is uniform and stable, which can ensure accurate synchronous conveying; At the same time, the structure is beautiful and the operation noise is low. Intelligent pallet four-way shuttle car is an important storage and logistics transportation equipment. It is a channel and bridge connecting the operation area, the production site and the storage area. It has the advantages of high degree of automation, saving manpower and time, convenient and fast operation, improving operation efficiency and so on. It usually forms an intelligent storage intensive system after being connected with the upper computer.

Software scheduling of intelligent pallet four-way shuttle is the key

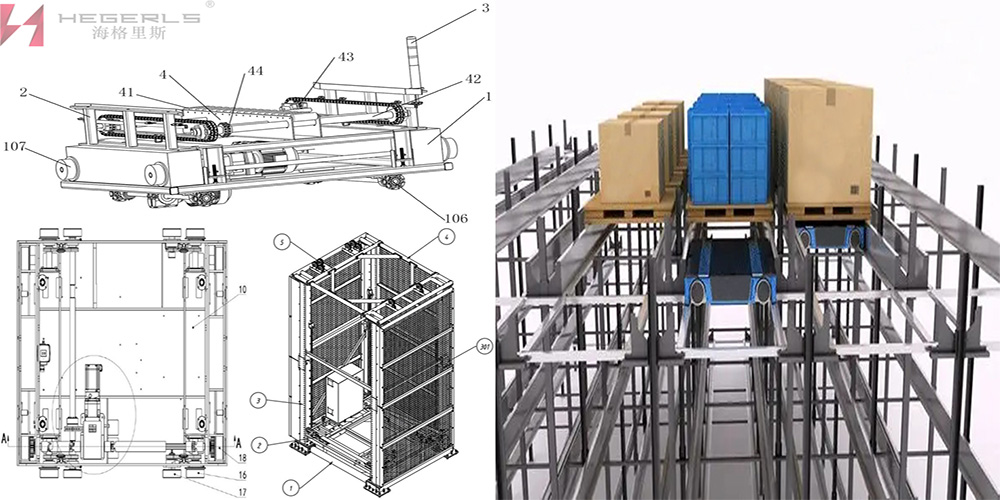

As an important part of hegerls storage solution, the intelligent pallet four-way shuttle car system includes four-way shuttle car, special elevator, shelf system, accessory system (supporting charging station, conveyor, remote controller, network, electric control system) and hegerls scheduling software system. As the pallet four-way vehicle system involves multi vehicle scheduling and collaborative operation with relevant equipment such as hoists, the ability of scheduling software will directly have a significant impact on the efficiency of the system.

The pallet four-way vehicle solution is not a simple dense storage system, but a highly flexible and dynamic intelligent storage solution. Its core advantage lies in discrete equipment + distributed control, which means that customers can flexibly configure the number of four-way vehicles according to their needs and schedule their efficient operation through software. It is worth mentioning that in addition to stable and reliable intelligent hardware products, haggis herls also has super large cluster scheduling intelligent software.

As standardized products, pallet four-way cars can be replaced with each other, and any four-way car can continue to perform the task of problematic four-way cars. The number of four-way vehicles is comprehensively determined by factors such as the roadway depth of the shelf, the total freight volume and the frequency of entry and exit. With the continuous improvement of the body design, the pallet four-way shuttle has gradually become an intelligent handling robot. Its operation efficiency and flexibility have been greatly improved, and its application is no longer limited to the storage of goods in the shelf. It can be used in front of the warehouse for handling, picking and other scenarios, which undoubtedly greatly increases the difficulty of system scheduling.

In addition to cluster scheduling, we also need to consider ‘multi-objective collaboration’. These tasks are serial for as/rs, but the jobs in the four-way shuttle system are parallel, and multiple tasks are interdependent. It is necessary to judge which four-way vehicle is the most efficient operation mode, because there are many uncertainties in the system. In addition, we need to judge the resource conditions, including order resources, container resources, warehouse location resources, vehicle resources, etc. we also need to cooperate with various equipment such as hoists and four-way vehicles to carry out the overall optimal scheduling of the system. Therefore, the scheduling software should be able to meet the key requirements of cluster scheduling, multi-objective, concurrency and collaboration. Higgins scheduling software has strong multi-objective coordination ability. It can improve the intelligence of four-way vehicles through AI algorithm, support the operation of multiple vehicles on the same floor, self detect and avoid obstacles, and increase system security.

Function framework of intelligent pallet four-way shuttle

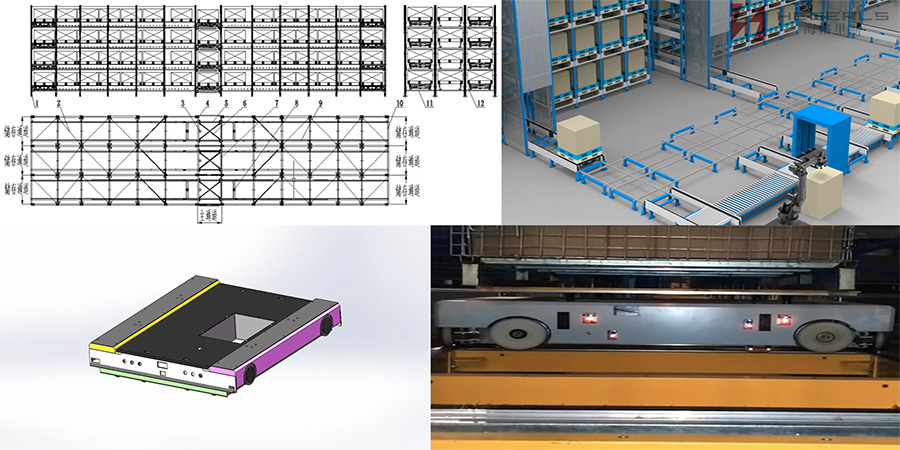

The pallet four-way shuttle automated dense storage system adopts pallet consolidation. The storage spaces in the shelf structure are densely arranged, and the storage depth of the goods grid is greater than 1 pallet. It has high storage space utilization and automatic operation ability, and has low requirements for the structure and height of the warehouse. The storage system is arranged in the warehouse, and cooperates with the assembly / disassembly platform, forklift (or ground AGV, which will be included in the forklift operation later) to complete the warehousing, loading and unloading operations. During the operation, the warehouse keeper, the tallyman and the forklift operator cooperate with each other under the commissioning of the management and control information system to complete the goods in and out of the warehouse. The facilities and equipment involved in the operation include forklifts, pallet four-way shuttles, shelves, servers (deployment management and control information system), pallets, RF tags, RF reading devices and handheld terminals.

The warehousing operation process of goods mainly includes four links: tally pallets – forklift transportation – conveyor line or other peripheral equipment – Pallet four-way shuttle transportation system (including vertical elevator transportation and pallet four-way shuttle transportation).

In the process of goods warehousing, first, the management and control information system formulates the warehousing operation plan according to the warehousing order. The tally and palletizing operators perform the palletizing operation of the arrived bulk goods, and upload the palletizing operation information to the management and control information system through the handheld terminal; Then, the pallet goods are put on the shelf. The forklift transports the pallet to the shelf port or the material port on the conveying line. The RF reading device installed at the port reads the RF tag on the pallet to obtain the pallet goods information, and the management and control information system assigns storage spaces to the pallet goods; Finally, the pallet four-way shuttle transports the pallet goods from the port to the designated location. The outbound operation process of the goods is opposite, and also includes four links: four-way shuttle transportation (including vertical elevator transportation and four-way shuttle transportation) – conveyor line or other peripheral equipment – forklift transportation outbound shipment (including unpacking and returning to the warehouse). The operation process is opposite to warehousing. The warehouse in and warehouse out operation must be based on the customer’s operation process, and the reasonable control node of the equipment must be set to ensure the efficiency and quality of the warehouse in and warehouse out operation.

As a new generation of pallet flexible logistics solution, hegris hegerls intelligent pallet four-way shuttle system has the advantages of high-density storage, strong site adaptability, flexible expansion, short delivery cycle and so on. It can provide automatic and intelligent warehousing solutions with better return on investment (ROI) for physical enterprises.

Post time: Aug-02-2022