With the continuous development of high and new technology, as well as the rising demand of domestic and international society, the rapid development of food industry, medical industry, tobacco industry, machinery industry, e-commerce, new energy and other industries also urges the continuous progress of the warehousing industry. Nowadays, the traditional warehouse shelf system can no longer meet the needs of large and medium-sized enterprises, so a variety of automated three-dimensional warehouses have emerged as the times require. Nowadays, the “goods to people” picking technology has also attracted more and more attention from the industry.

The “goods to people” picking system is mainly composed of storage shelf system, goods transportation system, picking system and goods packaging, among which the most important link is the storage shelf system. With the demand for warehousing from all walks of life, Hebei Walker Metal Products Co., Ltd., with its own brand of HEGERLS, has also carried out continuous research and development, design, production and put into use in major enterprises in response to the warehousing demand. At the same time, according to the feedback from the enterprise customers, Hebei Walker has also made further research and development and production on the storage shelf system, such as the four-way shuttle system, the multi-layer shuttle system, the two-way shuttle rack system, the shuttle+stacker rack system, the stacker warehouse, and the shuttle mother car rack system, which are all modern storage shelf systems with great development prospects. Among them, the four-way car and multi-layer shuttle car system are particularly favored by large enterprises from all walks of life. So here we will make a simple comparison between the four-way shuttle and the multi-layer shuttle to help customers choose their own shuttle storage shelves.

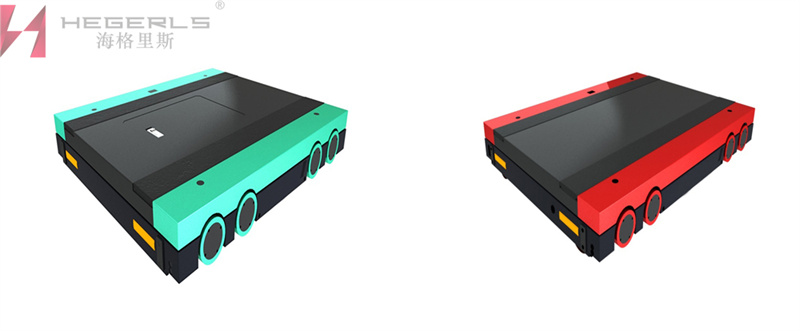

HEGERLS four-way shuttle

The HEGERLS four-way shuttle system is composed of four-way shuttle, fast hoist, horizontal conveying system, shelf system and WMS/WCS management and control system. It has the characteristics of high storage density, stable system operation and high security redundancy. Moreover, the HEGERLS four-way shuttle can automatically switch 90 degrees in the longitudinal storage lane and the transverse transfer channel. Of course, besides the characteristics of the general shuttle bus, it also has the warehouse storage mode in complex terrain scenes. In terms of structural components, all single machines and units are connected with each other under the support of wireless network. Under the dispatching of WMS/WCS upper management and control system, goods can be delivered and delivered in and out of the warehouse in a first-in, first-out or first-out manner.

HEGERLS Multi-layer Shuttle

The HEGERLS multi-layer shuttle car system is composed of multiple groups of shuttle cars (running on different layers of shelves), fast elevators, box conveyor lines, sorting lines, WMS/WCS and other components. It is a more advanced and efficient automatic storage mode applicable to box logistics instead of the traditional MINILOAD. The multi-storey shuttle has single-depth and double-depth design, two-way and four-direction design. The system is widely applicable to the logistics mode of light boxes such as auto parts and electronics.

HEGERLS takes you to choose the right three-dimensional four-way shuttle and multi-layer shuttle for yourself!

⏵ Flexibility

The four-way shuttle car can walk in any direction of “front, back, left and right”. It can reach any cargo position in the warehouse through the cooperation with wireless network, software system and elevator. It is a real three-dimensional shuttle car. The four-way shuttle car can also adapt to various irregular sites, greatly improve the utilization of warehouse space, and adjust the system capacity by increasing the number of shuttle cars; However, the multi-storey shuttle is different. It must work together with the supporting facilities at the end of the roadway, and its flexibility is also limited in many occasions.

⏵ Key technologies

In terms of technology, the technology of four-way shuttle is more complex than that of multi-layer shuttle. The four-way shuttle car should not only solve the problems of positioning, power supply and communication in the roadway, but also solve the problems of vehicle avoidance, vehicle scheduling, steering, layer change, especially the problem of route planning such as scheduling and avoidance; However, the multi-storey shuttle only needs to solve the most important problems, namely, the positioning, power supply and communication problems in the roadway.

⏵ Application scenario

The multi-layer shuttle system is characterized by low density storage and high speed picking, which is not suitable for operation scenarios with large storage capacity, but more suitable for large-scale rapid picking application scenarios; The four-way shuttle system is not only suitable for low-flow and high-density storage, but also suitable for high-flow and high-density storage and sorting. It can provide solutions to meet customer needs. In addition, from the height of the warehouse, too low space will cause the efficiency of the elevator to be unable to play, so the lower limit of the application of the multi-layer shuttle should not be less than 10 meters, and there is no limit for the four-way shuttle.

⏵ Cost

Another point is from the single machine cost. Under normal circumstances, the single machine cost of the four-way shuttle is higher than that of the multi-layer shuttle. At the same time, due to the transverse track, the four-way shuttle car has higher requirements for the accuracy of the rack, and its installation accuracy is also more rigorous, and its installation duration and cost will also increase correspondingly; Secondly, the four-way shuttle vehicle relies on scheduling technology, which also greatly increases the cost of technical threshold; Moreover, from the aspect of maintenance, due to the uncertainty of the position of the four-way shuttle in the roadway, the horizontal track limits the maintenance personnel to carry out the interior of the shelf, so if there is a problem, the maintenance difficulty will increase, that is to say, higher requirements are put forward for the overall design and technical level, and the cost will also increase relatively. However, in this regard, the utilization rate of the HEGERLS four-way shuttle is high, and the number of use is small, and the total number of supporting hoists will also be relatively reduced. However, when an enterprise warehouse selects the storage shuttle rack system, it still needs to be determined according to the specific project requirements.

Since its establishment, Hebei Walker has been focusing on the research and development of four-way shuttle cars. The company’s intelligent Hercules HEGERLS four-way shuttle cars are all of pure mechanical structure, stable and durable, and do not need frequent replacement of hydraulic oil and other maintenance operations, which greatly reduces the maintenance and investment costs. At the same time, it is compatible with the two-way shuttle shelf, which greatly reduces the upgrade costs of the library. Hebei Walker Intelligent Hercules HEGERLS four-way shuttle has lighter and thinner body and higher patented load technology. At the same time, it has designed and developed a number of models and four-way shuttle for cold storage, which can be customized according to customer needs!

Post time: Mar-02-2023