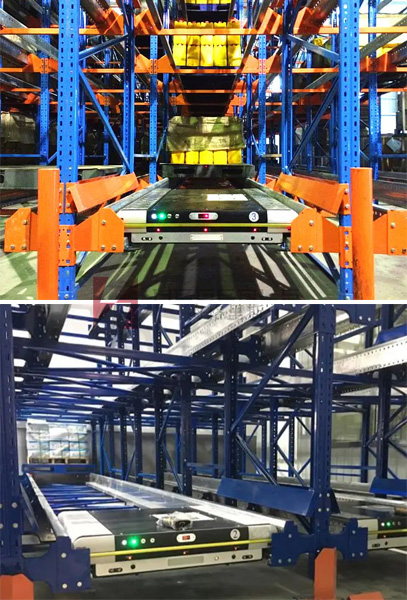

The current logistics industry is transitioning from labor-intensive to technology-intensive, and logistics systems are increasingly showing a trend of automation, digitization, flexibility, and intelligence. Automated warehousing systems, represented by stackers, have high site requirements for picking up goods and are often built in new warehouses with a capacity of over 12M. For irregular and low story old warehouses, due to limited conditions, manual forklifts are often used to pick up goods. Based on this, the pallet four-way shuttle vehicle has emerged. The pallet four-way shuttle is not limited by the height of the warehouse, and can fully utilize the area. Different depths are set multiple times according to the batch of materials, and investment is made in batches according to the efficiency requirements of different periods.

With the rapid development of the cold chain market, due to reasons such as insufficient cold storage capacity, outdated infrastructure, and lack of management mechanisms, there is often a phenomenon of “chain breakage”, which seriously threatens product quality and consumer safety. Based on this, in recent years, the development of cold chain intelligent warehousing has been rapid both domestically and internationally, and cold chain intelligent warehousing construction projects have also blossomed everywhere. Based on the current situation of the cold chain industry, Hebei Woke Metal Products Co., Ltd. (self owned brand: HEGERLS) has developed and launched a pallet four way shuttle cold chain storage system, which controls management risks from a technical perspective and forms a safe, efficient, and complete monitored chain.

The HEGERLS pallet four-way shuttle cold chain storage system, which is a cold chain three-dimensional storage device mainly composed of the cold chain four-way shuttle and the steel rack structure used for cold chain, determines the throughput efficiency of the cold storage and is the core component of the cold chain cold storage. In the overall planning, the advantages of the pallet four-way shuttle can be fully utilized, connecting various storage areas through walls and profiles. The pallet four-way shuttle can be deployed into any storage area through the system to achieve equipment sharing. In previous designs, conveyor lines, RGVs, and other equipment were often used for tray transportation in the lobby area. The tray four-way shuttle car can also be used as a flat handling equipment in this area, further saving procurement costs for user enterprises.

Highlights of the Hagrid HEGERLS pallet four-way shuttle

1) Modular project implementation

Encapsulate details in handling, lifting, conveying, and scheduling processes, provide user interfaces, and reduce coupling between various processes and equipment. During the project implementation process, it is possible to maximize the design reuse of hardware devices and software systems, and meet more personalized needs more quickly with the minimum number of modules.

2) Integrated product design

The Hagrid HEGERLS tray four-way shuttle car three-dimensional warehouse system reduces the hardware product allocation process and software and hardware interface access scheduling time during the project implementation process by designing the products required for the tray storage three-dimensional warehouse business as a whole, and improves the feasibility of upgrading the intelligent shuttle car three-dimensional warehouse.

3) Intelligent project operation and maintenance

The supporting HEGERLS operation and maintenance system independently developed and launched by Hebei Woke can achieve preventive operation and maintenance. The system platform provides visual, remote, and preventive operation and maintenance services. In addition, the system incorporates high self-healing ability in the design process, achieving high fault tolerance and high availability.

4) Service oriented products

Provide a service-oriented intelligent shuttle vehicle warehousing product system that can analyze the algorithm of the Hagrid HEGERLS intelligent warehouse operating system, decompose and allocate tasks through autonomous optimization, and efficiently schedule WCS to control the intelligent devices in the entire warehouse to complete the assigned tasks, significantly improving the customer’s user experience.

5) Security assurance design

Preventive measures shall be taken to protect against emergencies such as collision of handling equipment, derailment of equipment operation, sudden failure of wireless network, etc. hazard identification, system safety analysis, evaluation and control shall be carried out through hardware installation of multiple precision detectors and implementation of design to ensure safety.

As a new generation of high-tech warehousing and intelligent logistics products and solutions provider, Hebei Woke HEGERLS Robotics, based on AI native algorithm capabilities and a one-stop platform for robots, continues to create industry benchmark cases, providing efficient and intelligent warehousing and logistics solutions for major cold chain cold storage customers at home and abroad. Hebei Woke HEGERLS Landing Example:

Case 1: A domestic food freezer project

In recent years, the scale of storage in the cold chain circulation market of cold storage has been continuously increasing. The traditional storage mode is mainly manual operation, and the frequent entry and exit of staff not only affects the stable environment of the warehouse, but also has low operational efficiency. A domestic food freezer project has achieved digital and intelligent transformation of cold chain warehousing through the transformation of the Hagrid HEGERLS intelligent shuttle vehicle three-dimensional warehouse, while improving the work efficiency of the enterprise and reducing investment costs. This project has designed and constructed a 4-layer pallet four-way shuttle vehicle dense storage system, customized installation of multi depth shelves dedicated to pallet four-way shuttle vehicles. Three customized cold chain HEGERLS pallet four-way shuttle vehicles are deployed inside the warehouse, which can operate stably in low temperature environments of -25 degrees Celsius, and are equipped with WCS and WMS systems. Intelligent scheduling is carried out based on the order quantity and actual operation situation of HEGERLS pallet four-way shuttle vehicles.

After the renovation, the volume ratio of goods in the warehouse has significantly increased by nearly 50%, comprehensively improving the warehouse capacity, and achieving unmanned operation in and out of the warehouse, improving the stability of the storage environment. Efficient coordination of intelligent software and hardware systems, achieving information technology and lean management of materials, as well as effective allocation of multi-level and multi regional shuttle vehicles.

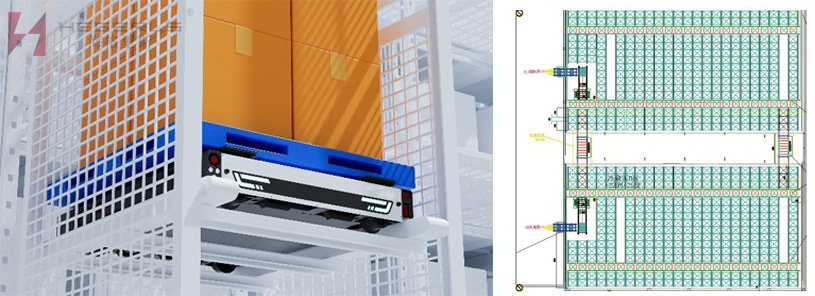

Case 2: Cold Storage Project of a Cold Chain Property Enterprise in Southwest China

The cold storage project of a certain cold chain property enterprise in Southwest China has a plan layout with a depth of 12/3, adopting a first in, last out mode. The shelf facade has a 6-story track layout, with a total of 13619 storage spaces, achieving an 88% warehouse utilization rate. Matched with 6 pallet four way shuttle cars (with pallet containing cargo specification of 1200mm) × 1100mm × 1540mm, with a load capacity of 1200kg/pallet, and an efficiency of 112 trays/hour, it can achieve 24-hour uninterrupted inbound and outbound operations. Realize the shared mode of tray four-way shuttle cars between storage areas. When a certain storage area is centralized for inbound and outbound operations, the system will allocate tray four-way shuttle cars from other storage areas for centralized operations, thereby reducing equipment investment and increasing the efficiency of single storage area operations. In order to avoid the loss of refrigeration capacity, the project divides the warehouse into multiple small warehouses of varying sizes. When the product storage capacity is small, small storage areas can be used for storage. Maximizing the utilization of space in the warehouse, designing a bidirectional tray four-way shuttle car running track in the lobby area, and using the tray four-way shuttle car as a flat handling equipment in the lobby area, not only meets efficiency but also reduces the financial investment of user enterprises.

Post time: May-22-2023