The warehousing and logistics industry has stepped into the era of automated system integration. The equipment with storage shelves as the storage subject has gradually developed into the storage mode of automated logistics system. The working subject has also changed from shelf storage to robot+shelf, forming a system integrated logistics storage system. As a storage system integrated with shelf+shuttle+elevator+picking system+control software+warehouse management software, The box type four-way shuttle has become an important carrier (unit bin cargo+light four-way shuttle) for lane changing operation and cargo storage, and the application of the box type four-way shuttle has been widely used for various storage integration. With the use of the box type four-way shuttle, it has also become a mainstream storage robot at home and abroad.

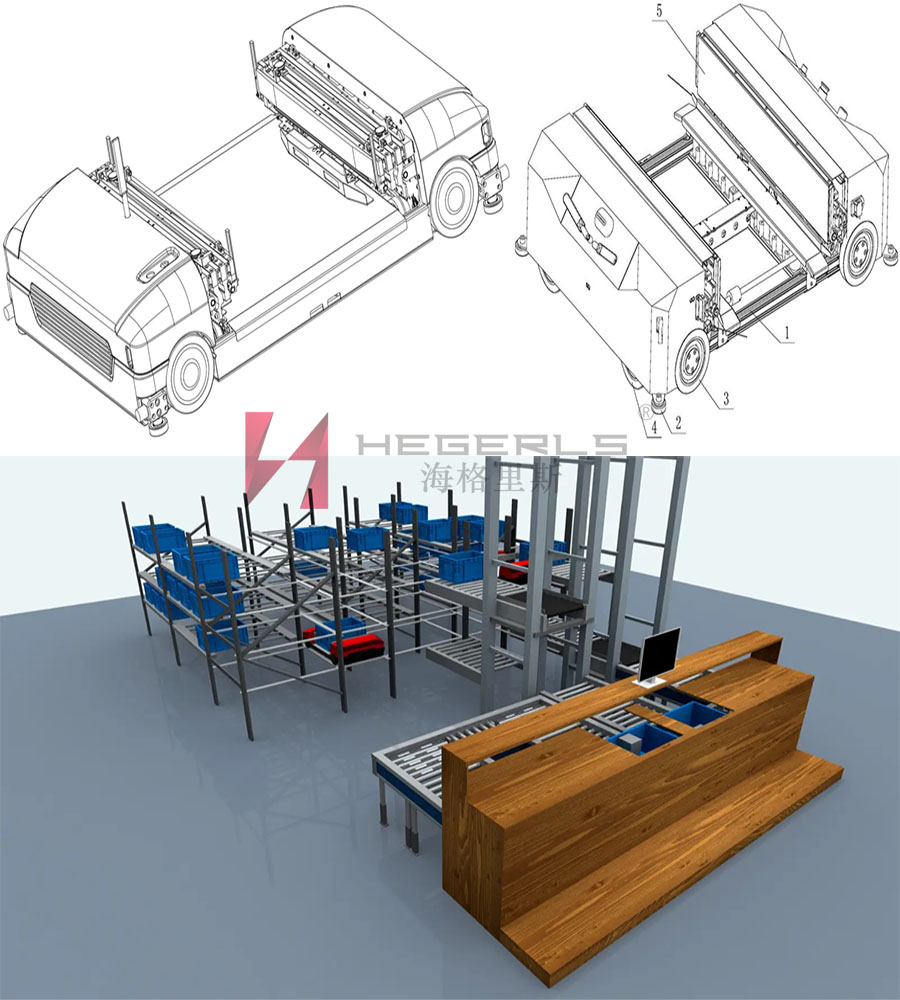

As the core transportation equipment of automated warehouse, shuttle cars have many kinds, and each kind of car has different scenarios and characteristics. The new generation multi scene box four-way shuttle solution of HEGERLS mainly consists of box four-way shuttle system, high-speed elevator system, box conveying system and picking operation system.

The HEGERLS multi scene box four-way shuttle car has evolved the flat "goods to people" system into a multi-layer 3D "goods to people" system. The efficiency of the single machine picking station is up to 900 order lines/hour. The picking efficiency of the system is 3-5 times that of the traditional Miniload system, and 15-20 times that of the pallet warehouse system. Intensive storage and distribution integration, flexible overall layout, flexible integration, and lasting endurance. At the same time, HEGERLS box four-way shuttle is distributed dynamic scheduling, mobile operation and maintenance, intelligent learning and self-healing, and supports different picking strategies in multiple scenarios.

What advantages does HEGERLS multi scene box four-way shuttle car occupy in the automated stereo warehouse?

Small footprint, efficient and flexible

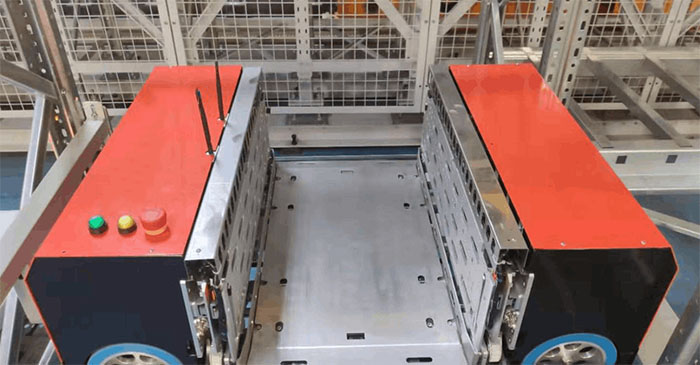

The maximum load of the trolley is 50kg, the maximum speed is 5m/s, and the maximum acceleration is 2m/s ², The positioning accuracy is ≤± 1mm. With the cooperation of the layer changing elevator, the vehicle can reach any cargo location of the intensive warehouse to pick up and place the goods. With the same processing capacity, the required channels will be much narrower, reducing space use and increasing storage area;

There are many options for warehouse layout

The box type four-way shuttle car system can be arranged anywhere in the warehouse, which has low requirements for the warehouse, and is also suitable for the warehouse with irregular shape;

Flexible, modular and scalable

Through the flexible lane change function, it can meet the cargo loading and unloading operation at any position on the same floor, and can work with multiple units on the same floor to meet the actual use of the project. The system can carry out lean configuration of equipment according to the actual business development needs of users; Seamless 5G high-speed WIFI communication technology ensures real-time communication and information feedback of the trolley, intelligent sensing and braking of the car body, and safe operation of the system.

Energy saving

Compared with the traditional handling equipment, the box four-way shuttle has less power consumption for single operation due to its lighter weight. At the same time, the block and ultra light structure design, the automatic switching technology of excess capacity and lithium battery, and the four-way shuttle energy recovery technology can recover the energy during the deceleration process, further reducing the energy consumption of the entire handling system;

Intelligent four-way shuttle system

The intelligent identification algorithm can automatically detect whether the bin position is offset or inclined. Before picking up, the vehicle can intelligently detect the bin offset to avoid abnormal alarm due to bin dislocation. According to the current task status and four-way shuttle operation status, the task is optimized globally to maximize the overall efficiency of the four-way shuttle system, so as to achieve the most economic investment and meet the use requirements of the enterprise warehousing system.

The HEGERLS new generation multi scene box four-way shuttle bus solution is widely used in e-commerce, cross-border e-commerce, medicine, footwear, fresh food, parts production, 3C electronic industry's line edge warehouse/raw material warehouse/semi-finished product warehouse/finished product warehouse, as well as some special scenes such as multi floor warehouse, irregular warehouse, trans regional office. The site is not limited, and the number of floors is recommended to be 12-15. As a system solution provider, HEGERLS has rich experience in intelligent warehousing and intelligent logistics planning and implementation. Compared with a single equipment manufacturer, HEGERLS can provide customized development based on multiple scenarios that meet the actual needs of customers in multiple industries and have high cost performance, as well as project planning, customization development, product manufacturing, project implementation, project operation and maintenance Modular expansion covers the service capability of the whole life cycle.

Post time: Dec-05-2022