With the diversification and complexity of logistics demand, four-way shuttle technology has flourished for several years and is increasingly being applied in various fields. Hebei Woke, as a representative in this field, has achieved rapid development with its large product group, powerful software system, and resource rich ecological partner system. Among them, the HEGERLS four-way shuttle, as a new storage technology, has also attracted attention for its flexibility and other characteristics through continuous technological iteration and core upgrades, becoming a flag in this field.

Hebei Woke has always been positioned as a production-oriented technology enterprise, attaching great importance to investment and layout in technology. Since its establishment, it has focused on four-way shuttle technology, and with years of logistics experience and technical accumulation, it has independently developed core logistics and warehousing equipment such as two-way shuttle, four-way shuttle, and stacker crane, providing customers with consulting and planning, software development, equipment manufacturing, and project implementation An end-to-end service that integrates operational coaching and after-sales service.

The four-way shuttle system technology requires very high comprehensive capabilities in positioning accuracy, control, software system scheduling, and other aspects. It is precisely because of its pursuit of excellence in every component that Hebei Woke gave birth to its independent brand, the HEGERLS four-way shuttle, after over a million tests. Both the stability and overall performance of its products have been widely recognized in the market. Overall, Hebei Woke mainly builds its strong technical foundation and solution capabilities through three lines.

1)Product cluster

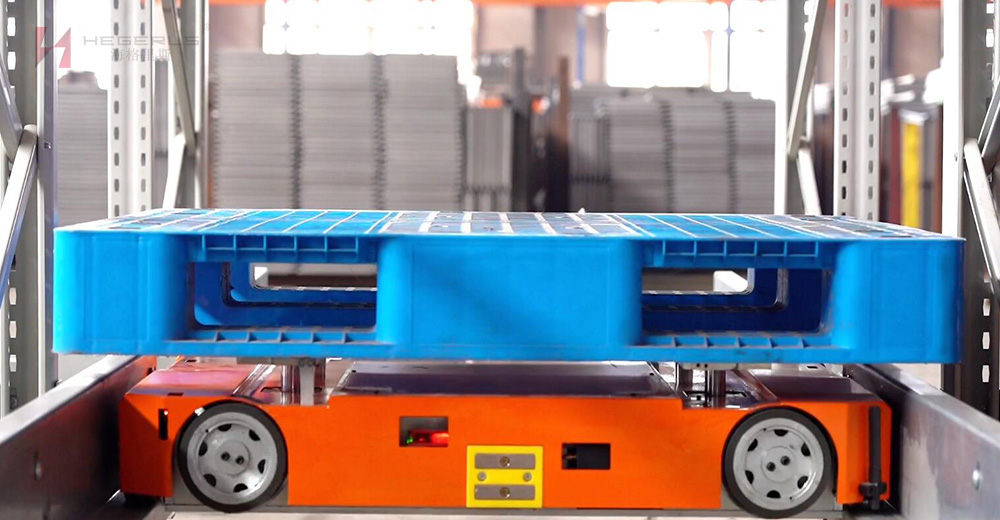

As is well known, warehouse operations are mainly carried out through storage and retrieval, handling, picking, conveying and sorting. Hebei Woke has a self-developed and self-produced product cluster. On the basis of successfully developing the Hegelis HEGERLS four-way shuttle, there are mainly two aspects to focus on: first, the horizontal expansion of the four-way vehicle has been added to the operation. That is to say, it has expanded from box type four-way shuttle cars to tray type four-way shuttle cars, and then to AMR warehousing robots responsible for ground handling, as well as sorting and warehousing equipment for different flow rates; The second is to further apply warehousing equipment, such as in the field of new energy storage batteries, AS/RS with fire extinguishing devices and smoke and temperature sensing, as well as mechanical arms, and so on.

2)Software system

Having hardware alone without inherent software support is not enough to solve customers’ comprehensive problems, so it is necessary to rely on a powerful software system. Before the official establishment of Hebei Woke, relevant accumulation of warehousing software systems began, forming a unique warehousing robot scheduling and control system, which includes the new generation of warehouse management system (WMS) and the new generation of warehouse control system (WCS). In its vast product portfolio, software systems account for approximately 1/5. Compared to traditional software, this software is relatively more mature, but it only targets traditional warehouse operations without many automated equipment, and only guides staff to complete various tasks. It should be noted that in a modern logistics center, it contains automation equipment and robots of different brands and functions, such as stackers, shuttle cars, conveyor lines, and various sorting equipment. These storage equipment need to be combined together to complete the entire process of warehouse from receiving goods to shipping and order management. Therefore, as a command system, software needs to change from “manager” to “management equipment”, Both its functionality and architecture need to be updated. The Hebei Woke robot scheduling and control system is precisely such a software system that can manage various types of warehouse robot equipment.

3)Bottom level technical support

Based on AI algorithms, 3D vision, digital twins and other technologies, Hebei Woke’s artificial intelligence research and development team has independently developed many core technologies, including AMR/AGV motion control systems, shuttle control systems, etc. In recent years, the company has increased its research and development efforts in automated warehousing equipment, and has successively won national patents for two automated warehousing equipment: intelligent shuttle cars and intelligent sheet metal storage stackers. Relying on these internationally leading automated warehousing equipment, Haigris has successively completed projects such as the OSCAR automated cold storage warehousing project in Chile, the A&A series supermarket project in Mexico, the JM automated warehousing project in Thailand, the LSP automated warehousing project in Thailand, the ALLM automated warehousing project in the United Arab Emirates, and the BIO warehousing project in Algeria, The MDF/HDF board intelligent picking and automated warehousing project completed by FX Group in South Africa in 2017 is internationally leading and innovative. We have basically completed the transformation from exporting primary products to exporting complete sets of automation equipment and undertaking warehousing projects.

Based on its strong product innovation capabilities and profound technological accumulation, Hebei Woke has currently formed a core product group with access technology as its core, constantly expanding into multiple scenarios such as handling and sorting. At the same time, in the access field, it will further improve the layout of the entire series of robots, so that they can adapt to all building characteristics and different access forms such as bins and pallets, At the same time, further improve the operational efficiency and dense storage capacity inside the floor warehouse; In terms of handling technology, differentiated bin and pallet robots will also be launched.

Post time: Jan-22-2024