Benefiting from the rapid development of e-commerce, there is a strong demand for warehousing automation both domestically and internationally. Especially in recent years, against the backdrop of rising labor costs, various large warehouses and sorting centers at home and abroad have increased their efforts in automated warehousing construction. In this context, tray based solutions that can achieve dense storage, space utilization, and flexible scheduling, mainly with intelligent four-way shuttle vehicles, have begun to emerge in intelligent warehousing.

In the context of manufacturing enterprises, as physical enterprises face challenges such as demand diversification, real-time order fulfillment, and accelerated business model iteration, customers’ demands for logistics solutions tend to be flexible and intelligent. Based on this trend, Hebei Woke has launched the Hagrid HEGERLS intelligent pallet four-way shuttle, filling the gap in flexible solutions in the field of pallet handling previously. In today’s market, pallet shelves have become the most common type of storage shelves used in modern industrial warehouses, logistics centers, distribution centers, and other scenarios.

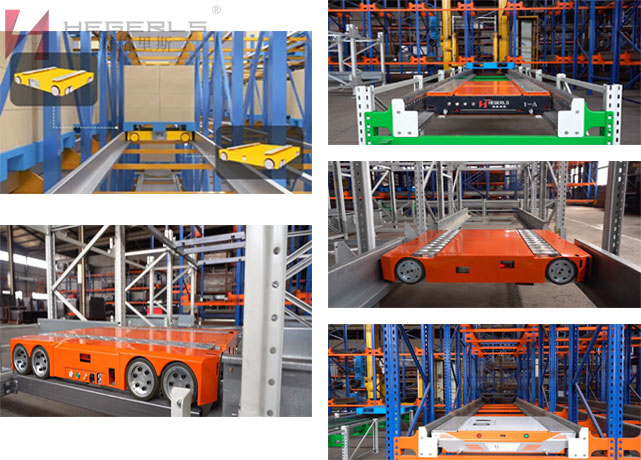

The Hagrid HEGERLS intelligent tray four-way shuttle car includes a four-way shuttle car, a dedicated hoist, a shelf system, an accessory system (including a charging station, conveyor, remote control, network, and electrical control system), and a HEGERLS scheduling software system. Due to the involvement of multi vehicle scheduling and collaborative work with related equipment such as elevators in the tray four-way vehicle system, the ability of scheduling software will directly have a significant impact on system efficiency. The Hagrid HEGERLS intelligent tray type four-way shuttle has six major advantages: “ultra-thin”, “ultra fast”, “ultra safe”, “longer endurance”, and “super large-scale cluster scheduling”, which can greatly improve the production efficiency of enterprises. This autonomous mobile robot that can run on shelves can further improve the utilization rate of warehouse space by 30% compared to traditional logistics automation solutions. At the same time, the HEGERLS intelligent tray four-way shuttle car has a body size of only 125 millimeters, weighs 300 kilograms, and is compact and sturdy. It can also handle items weighing 1 to 1.5 tons, making it more flexible to operate. Compared to a 10 ton stacker, it can further save more than 50% of electricity. Compared to traditional logistics automation solutions, a flexible body can shuttle between shelves, increasing both operating speed and storage density, making it particularly suitable for cold storage, new energy and other operational scenarios.

The Hagrid HEGERLS intelligent tray four-way shuttle solution is not a simple dense storage system, but a highly flexible and dynamic intelligent warehousing solution. Its core advantage lies in distributed control of discrete devices. It is precisely because of this feature that users and enterprises can flexibly combine and deploy as needed, just like building blocks. Unlike AS/RS stackers, which can only operate on fixed paths, the four-way vehicle system is standardized due to its hardware product, which can be replaced with a new car at any time in the event of a malfunction. Secondly, flexibility is reflected in the “dynamic scalability” of the entire system, where users and enterprises can increase or decrease the number of four-way vehicles at any time according to changes such as off-season and business growth, thereby improving the system’s carrying capacity. In addition, discrete devices are closely related to scheduling and algorithms, while distributed control is actually on every vehicle, which is in line with AMR control platform technology. The scheduling strategy of HEGERLS can not only control each four-way vehicle, but also provide algorithms for changes in inbound and outbound volume, allocation of transportation capacity, warehouse location optimization, and path optimization. In terms of discrete equipment scheduling or overall system efficiency improvement, the biggest core capability comes from software, which is the advantage of the Hagrid brand series of products. In addition, the Hagrid HEGERLS intelligent tray four-way shuttle also has the following advantages:

1) Intelligent control

Effectively improving the efficiency of goods storage and utilization of warehouse space. The integration of WMS and WCS system software with enterprise ERP, SAP, MES and other management system software can also maintain the first in, first out rule of goods and eliminate the confusion or low efficiency of human factors in operations.

2) Intelligent layer switching

Cooperating with the elevator, the shuttle car can achieve efficient work mode of automatic and precise layer changing; Realize three-dimensional operation of space. Accurately control the entry and exit of each storage location within the steel shelf area.

3) Location Dynamics Management

Traditional warehouses are just places for storing goods, and preserving goods is their only function, which is a type of “static storage”. The pallet four-way shuttle is an advanced automated transportation equipment that not only allows goods to be automatically stored and stored in the warehouse according to the required information, but also can be organically connected to production processes outside the warehouse. Facilitate the formation of advanced logistics systems and improve the level of enterprise management.

4) Effectively improving storage space utilization

The low storage density of traditional warehouses results in low utilization of the total area and storage space of the warehouse. The pallet four-way shuttle truck runs in four directions on the main track inside the shelf, and can automatically complete the operation without the coordination of forklifts and other equipment. Due to the volume of the main track of the shelf being smaller than the volume of the forklift operation channel, the pallet four-way shuttle automation system further improves the utilization of storage space compared to the ordinary shuttle truck shelf system, It can increase by about 20% to 30%, which is 2-5 times that of a regular warehouse;

As a “new generation of pallet flexible logistics solution”, the HEGERLS intelligent pallet four-way shuttle, combined with the HEGERLS software platform, can achieve swarm intelligence and make greater use of the storage space of the warehouse. In addition, the Hagrid HEGERLS intelligent pallet four-way shuttle will be arranged according to different SKUs and storage locations, and the algorithm will automatically recommend suitable storage locations when items are stored in the warehouse, allowing goods to be stored according to certain rules and avoiding congestion during later outbound operations, improving efficiency; When leaving the warehouse, the algorithm also recommends the optimal storage location, and calculates various factors such as distance, hindrance to tasks, and final inventory to provide the optimal storage location; It can also achieve inventory visualization and easily view the status of any storage location through a graphical interface, with strong adaptability, high reliability, strong scalability, and high flexibility.

Post time: Apr-26-2023