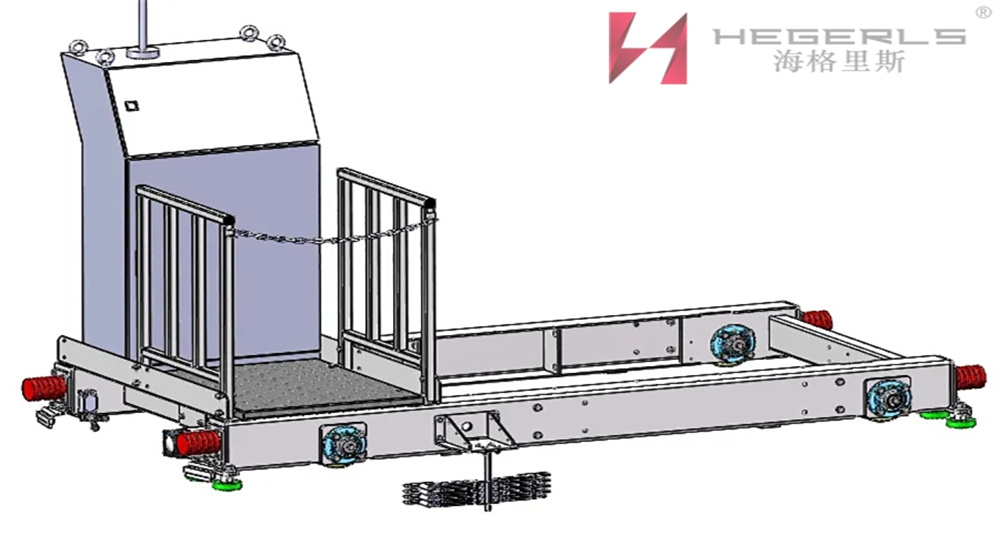

The new unattended rail type shuttle car, namely rail guided vehicle (RGV), is a kind of high-performance and flexible cargo handling equipment. It can complete the taking, placing, transporting and other tasks of pallets or bins through program control, communicate with the upper computer or WMS system, and realize real-time monitoring and scheduling. The vehicle body is equipped with drive wheels and guide wheels to ensure that the vehicle body moves along the track. The goods are mainly transported by chain or roller. As a kind of fixed track handling equipment in the automated logistics system, it is the main conveying equipment in the complete set of automated three-dimensional warehouse equipment. It is used together with shelves, warehousing platforms or tray conveyors for the horizontal conveying of empty pallets or loaded pallets.

Hegerls-rgv rail shuttle

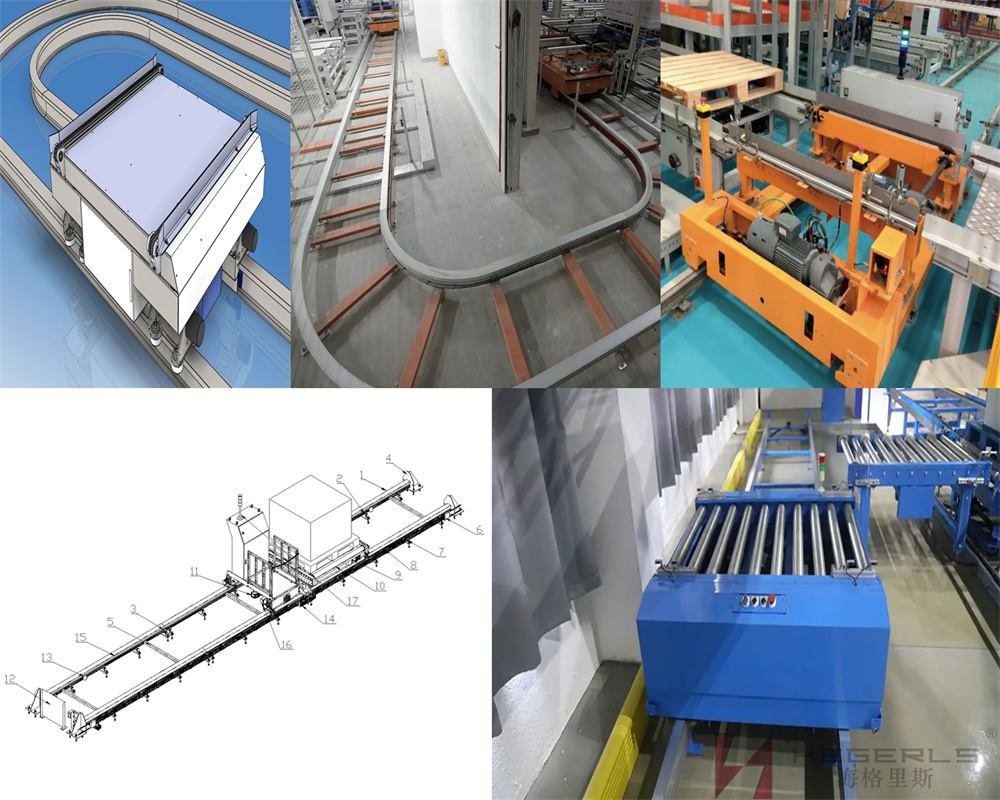

RGV rail shuttle car, also known as RGV rail collection truck and RGV rail automatic truck, namely, it moves back and forth on a straight track and transports items to the set position through the straight track path. The shuttle car in this mode has the advantages of unattended, simple system, small equipment, small area occupied by the transportation system, fast transportation, etc. it uses sliding contact line for power supply, bar code positioning or laser positioning, operates on the preset guide rail, and is used to connect multiple logistics nodes. It has the characteristics of fast, flexible, simple configuration and easy maintenance. It can replace the relatively complex and poor mobility conveyor system in some logistics schemes.

Hegerls-rgv rail shuttle

RGV rail shuttle car, also known as RGV rail collection truck and RGV rail automatic truck, namely, it moves back and forth on a straight track and transports items to the set position through the straight track path. The shuttle car in this mode has the advantages of unattended, simple system, small equipment, small area occupied by the transportation system, fast transportation, etc. it uses sliding contact line for power supply, bar code positioning or laser positioning, operates on the preset guide rail, and is used to connect multiple logistics nodes. It has the characteristics of fast, flexible, simple configuration and easy maintenance. It can replace the relatively complex and poor mobility conveyor system in some logistics schemes.

Working principle of hegerls-rgv rail shuttle

Working principle of RGV rail shuttle: the upper control system sends the task to the shuttle dispatching system, and the shuttle dispatching system decomposes the task to each shuttle through wireless communication. Each shuttle returns the information after completing the task according to the instructions, and the shuttle dispatching system feeds back the relevant information to the upper control system.

According to the working mode of the system, the key points of RGV rail shuttle in operation are specifically reflected in the following points:

1) Task assignment

The upper control system assigns the task to the shuttle car dispatching system, which assigns the task to each single shuttle car according to the principle of task priority according to the best route, vehicle location, etc.

2) Safety planning

The graphic monitoring surface can simulate and display the distance between adjacent cars in real time through the shuttle car return information. If it is within the dangerous distance, it will issue instructions to the relevant shuttle cars to avoid; The shuttle can also detect the distance between the shuttle and adjacent vehicles, and avoid them if they are too close.

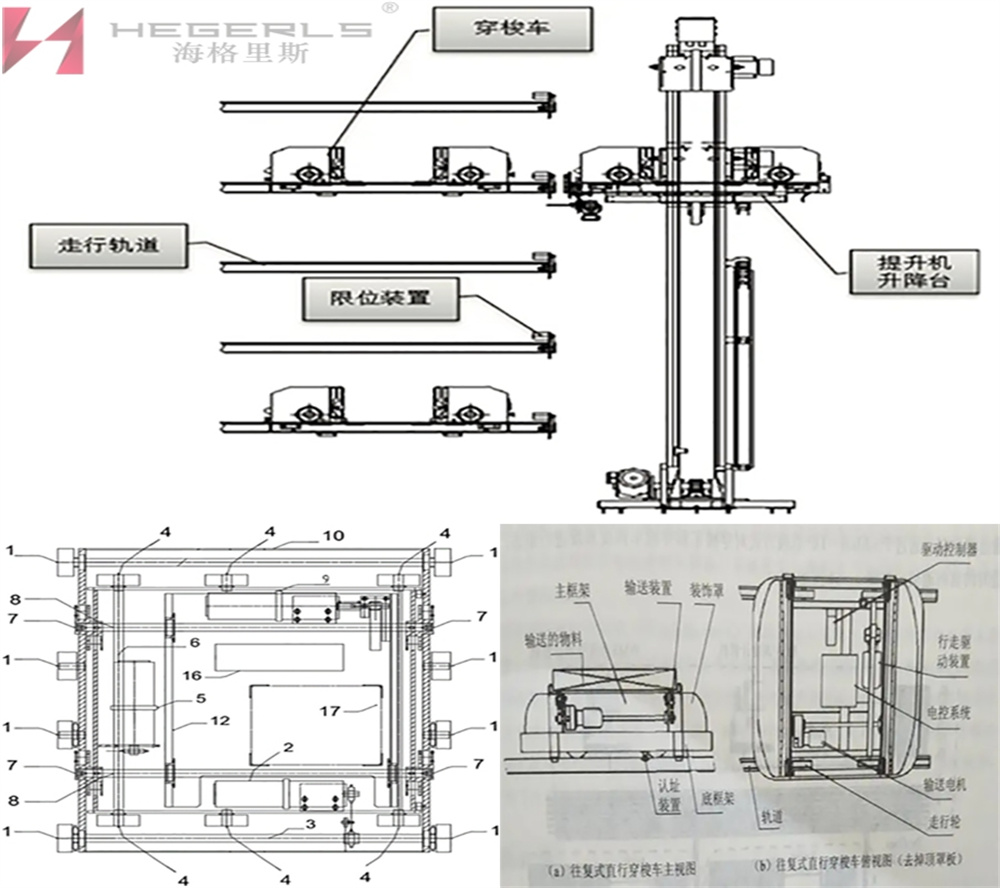

3) Shuttle straight and turning

The straight travel and turning of the shuttle are controlled by a single machine electronically. The single machine electronic control ensures the consistent speed of the front and rear traveling wheels through the “digital lock” technology when going straight, and the differential matching of the front and rear traveling wheels when turning to ensure the stable operation of the shuttle.

4) Communication transmission

The shuttle dispatching system receives various task instructions from the upper control system through cables and feeds back the execution of relevant tasks; The shuttle car dispatching system sends the relevant task information to each shuttle car through wireless communication. When the shuttle car executes the task, it feeds back the task completion to the shuttle car dispatching system.

The whole execution process is as follows: after receiving the cargo transportation instruction from the upper control system, the vehicle dispatching system determines the vehicle performing the task according to the current vehicle position and status, and sends the execution signal to the specific vehicle. The vehicle receiving the signal will complete the task of picking up or delivering goods under the control of the electronic control system.

Hegerls-rgv rail shuttle classification

According to the movement mode, it can be divided into ring track type and linear reciprocating type. The ring track type RGV system has high efficiency and can work with multiple vehicles at the same time. Generally, aluminum alloy track is used, and the cost is relatively high; A linear reciprocating RGV system generally includes an RGV for reciprocating motion. Generally, the rail is used as the track. The cost is low and the efficiency is relatively low compared with the annular RGV system. The maximum traveling speed of RGV is 200m/min. It communicates with the upper computer or WMS system, and combines RFID, bar code and other identification technologies to realize automatic identification, access and other functions. RGV rail shuttle vehicles generally use battery, rail power supply and sliding contact line power supply, which depends on the running distance of the vehicle.

The advantages of hegerls RGV rail shuttle are as follows:

- the size and load of the workbench can be customized according to user requirements;

- optional imported and domestic industrial wireless remote control equipment;

- optional imported wireless two speed control;

- automatic shutdown can be selected to send out alarm in case of 2m fault;

- the maximum capacity can reach 500t;

- sturdy trolley frame;

- remote control and hand crane control for more convenient operation;

- adjustable speed;

Hebei hegris hegerls storage shelf manufacturer is a one-stop storage service provider with its own factory, strict quality control and multi-directional service tracking. Its main products include: automated three-dimensional warehouse, shuttle car three-dimensional warehouse, stacker car three-dimensional warehouse, integrated three-dimensional warehouse and frame, automated three-dimensional cold storage, child and mother car three-dimensional warehouse, multi-layer shuttle car three-dimensional warehouse, automated three-dimensional warehouse shelves, heavy beam type shelves Heavy layer shelf, shuttle shelf, attic shelf, attic platform, steel structure platform, narrow lane shelf, conveyor line, elevator, shuttle, stacker, AGV, WMS, WCS and other logistics storage equipment.

Advantages of hagerls storage shelf manufacturer:

- own factory

Directly operated by the factory, with careful material selection and high cost performance, customers can visit the factory and negotiate cooperation at any time!

- various styles

With independent R & D and design, various styles and varieties, haggis strives to meet the needs of every user and provide high-quality services!

- quality assurance

Directly operated by the factory, the quality is guaranteed, and the quality is controlled from the source, thus eliminating the difference between middlemen and users!

- after sales delivery

From demand research, planning and design, installation and commissioning, delivery and acceptance, professional one-to-one full service!

Post time: Jun-07-2022