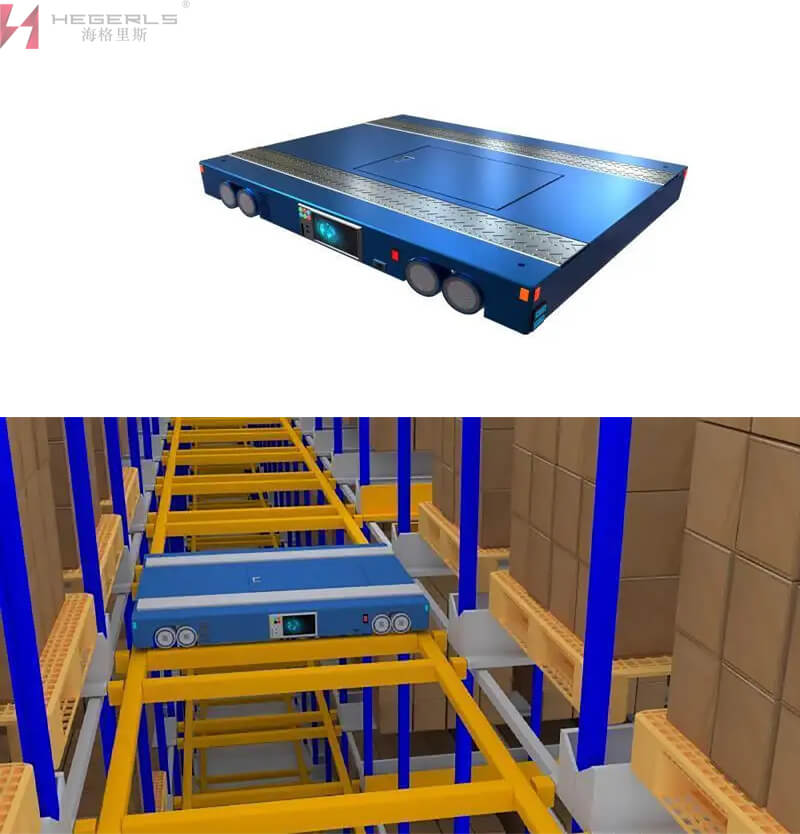

With the wide application of automated warehousing and logistics systems, logistics equipment tends to be more diversified. For example, a four-way shuttle car that can travel on the rack track has emerged as the times require. As a new type of logistics storage equipment, the heavy four-way shuttle car usually has two walking systems on the track plane with the direction of travel perpendicular to each other. By switching the two walking systems in the height direction, the two walking systems can contact the track respectively, In this way, the shuttle can travel in four directions. How much do you know about the internal structure, track reversing components and track system of the heavy four-way shuttle? In this regard, HEGERLS now makes a detailed and in-depth analysis of the track reversing components and the relevant structures of the track system of the heavy four-way shuttle car for you, so as to help major enterprises better put them into use!

HEGERLS – Four way shuttle

Four way shuttle car, that is, shuttle car that can complete ‘front, rear, left and right’ operation. It is relative to the multi-layer shuttle car. From the structural point of view, the former has two sets of gear trains, which are respectively responsible for the X-direction and Y-direction movement; The latter has only one gear train, which is the most typical difference. In terms of system composition, it is similar to the multi-layer shuttle car system, mainly including hardware equipment such as shuttle car, layer changing elevator, rail conveyor line and shelf system, and software such as equipment scheduling control system WCS.

The four-way shuttle car is equivalent to an intelligent robot. It is connected to the WMS system through the wireless network, and can go to any cargo space with the hoist. The roadway can be changed at will, and the number of shuttle cars can be increased or decreased at will to adjust the system capacity. The four-way shuttle system is modular and standardized. All trolleys can be replaced with each other, and any car can continue to perform the task of the car in question.

HEGERLS – Working Principle of Four way Shuttle

The inventory principle of the four-way shuttle truck is to place the pallet unit goods in front of the tunnel guide rail of the four-way shuttle truck rack through a forklift or a stacker. Then the warehouse workers use the radio remote control to operate the four-way shuttle car to carry the pallet unit to run on the rack rails and transport it to the corresponding cargo space. The four-way shuttle can be placed on different rack rails by forklift or stacker, and one four-way shuttle can be used for multiple rack tunnels. The number of four-way shuttle cars is determined by the comprehensive factors such as the roadway depth of the shelf, the total freight volume and the frequency of inbound and outbound.

HEGERLS – Track reversing component and track system of four-way shuttle car

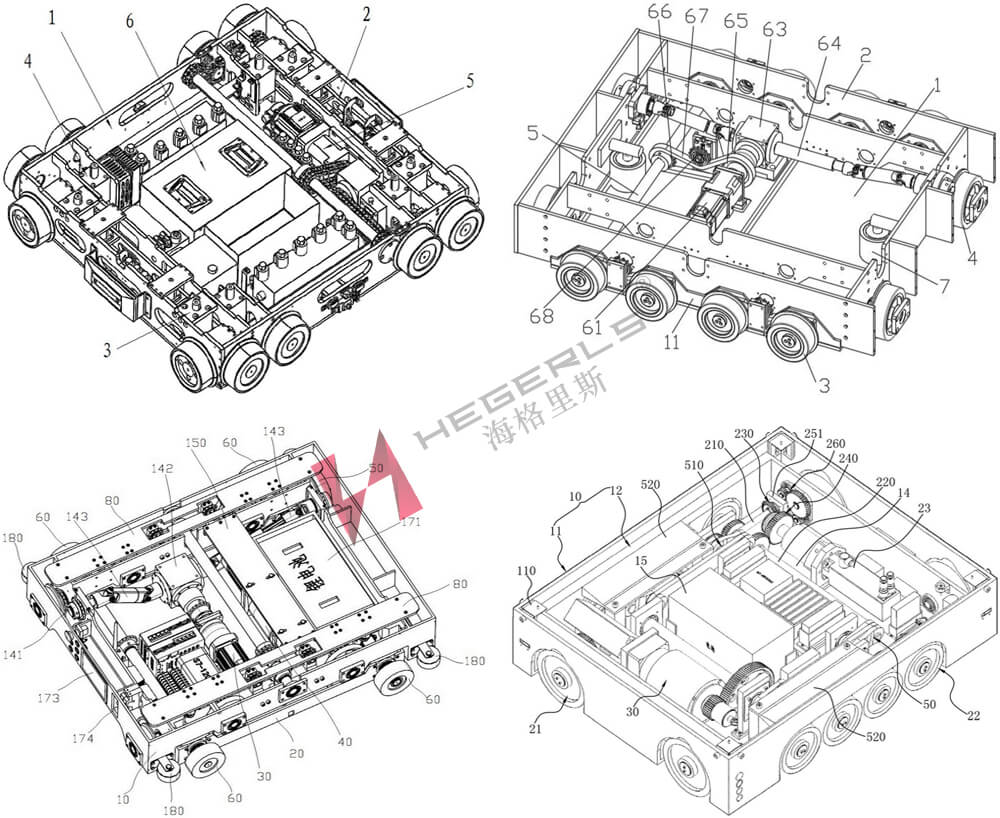

The track reversing component and track system of the four-way shuttle car include two main tracks arranged in parallel, two reversing tracks connected between the two main tracks and two pairs of main track support devices supporting the two main tracks; The extension direction of the main track is perpendicular to the extension direction of the reversing track, and the upper surface of the main track and the upper surface of the reversing track are in the same horizontal plane; The two ends of the reversing rail are respectively connected to the inner side of the two main rails. The reversing rail has a lower end face connected to the inner side of the main rail and an upper end face with a gap left with the inner side of the main rail. The gap between the upper end face and the inner side of the main rail is used as a guide gap; Each pair of main track support devices are symmetrically arranged on the outer side of the two main tracks, and the two reversing tracks are located between the two pairs of main track support devices. Such component structure can organically integrate the main track with the reversing track to ensure the smooth reversing operation of the four-way shuttle car.

The track reversing component and track system of the four-way shuttle car, wherein the reversing track can ensure the smooth reversing operation of the four-way shuttle car. Two main tracks are supported by two pairs of main track support devices, and each pair of main track support devices is symmetrically arranged on the outer side of the two main tracks. The two reversing tracks are vertically connected between the two main tracks. The upper surface of the reversing track and the upper surface of the main track are in the same plane, and the two reversing tracks are located between the two pairs of main track support devices, so as to achieve the organic integration of the main track and the reversing track, Let the whole shelf be connected into a stable whole. At the same time, a guide gap is set at the connection between the reversing track and the main track, so that when the four-way shuttle car is running on the main track, the guide device can directly pass through the guide gap without being blocked by the reversing track, ensuring the smooth operation of the four-way shuttle car. The structure occupies less space for the reversing track, and is simple in structure and easy to implement and maintain.

The track system of the track reversing component includes a plurality of track reversing components and a plurality of sub track systems correspondingly connected with the track reversing component. The plurality of track reversing components are arranged and connected in turn along the extension direction of the main track, and each track reversing component is connected with a sub track system at least on one side; The sub track system includes two sub tracks set on the outer side of the main track and multiple pairs of sub track support devices supporting the two sub tracks. The two sub tracks extend on the extension lines of the two reversing tracks respectively. The sub tracks have track support surfaces, which are located on the same horizontal plane with the upper surface of the main track.

The track system is connected and matched with a plurality of sub track systems through a plurality of track reversing components to form a track system of four-way shuttle car. In the track system, the four-way shuttle car is guided by the inner side of the main track when the main track is running, and a guide gap is set between the reversing track and the inner side of the main track, so that the four-way shuttle car guide device can pass through the guide gap smoothly, avoiding the interference of the reversing track to the four-way shuttle car; The track support surfaces of the main track, reversing track and sub track are all located on the same plane, so that the four-way shuttle can smoothly run and transition between tracks. So as to ensure the stable operation of the four-way shuttle.

The track reversing components and track system of the heavy four-way shuttle car are specifically implemented as follows:

HEGERLS – reversing track assembly of four-way shuttle car

The track reversing component of the four-way shuttle car includes two main rails arranged in parallel. Two reversing rails are connected between the two main rails. Both ends of the reversing rails are respectively connected to the inner side of the two main rails. In order to ensure that the four-way shuttle car can stably reverse in the track reversing component, the extension direction of the two main rails is perpendicular to the extension direction of the two reversing rails, and the upper surfaces of the two main rails and the upper surfaces of the two reversing rails are in the same horizontal plane. That is to say, the track planes of the main track and the reversing track are on the same horizontal plane. In order to ensure that the guide device located at the inner side of the main wheel is not affected by the reversing track when the four-way shuttle is running on the main track, the reversing track has a lower end face connected with the inner side of the main track and an upper end face with a gap left with the inner side of the main track. The gap between the upper end face and the inner side of the main track is used as the guide gap, Thus, the guide device on the inner side of the main wheel of the four-way shuttle can pass through the guide gap, avoiding the interference between the running wheel and the reversing track.

In order to connect the whole shelf into a stable whole, the track reversing component is also provided with two pairs of main track support devices supporting two main tracks; Each pair of main track support devices are symmetrically arranged on the outer side of the two main tracks to stably support the two main tracks. At the same time, the two reversing rails are located between two pairs of main rail support devices, so that when the four-way shuttle car runs on the reversing rail, it will not be interfered by the main rail support device to achieve stable reversing.

The main track supporting device includes a column and a supporting piece, the supporting piece is installed on the column, and the main track is installed on the supporting piece. Specifically, the column is provided with a plurality of mounting holes, the support is provided with a counterbore corresponding to the mounting hole, and the support is installed on the column through a counterbore bolt; The support is also provided with a round hole corresponding to the installation hole, and the main track is provided with a countersunk hole corresponding to the round hole. The main track is connected with the support and the column through countersunk bolts. Then the countersunk bolt is used as the connection between the main track and the support and the column, because if the ordinary hexagon bolt is used, the bolt head will protrude, which may hinder the operation of the four-way shuttle, leading to failure. As the countersunk bolt can sink into the thickness of the material, there is no obstacle in the whole track reversing assembly, so that the four-way shuttle can run smoothly.

In order to make the assembly of the track reversing component simpler, the two ends of the reversing track are provided with clips, the inner side of the main track is provided with a slot, and the reversing track is connected to the main track through the clip and the slot. Cut a single ladder from the top surface to the bottom at both ends of the profile of the reversing track, and cut from the bottom surface to the top to form a groove on both sides. The groove on both sides forms a buckle. Cut the slit corresponding to the two slits on the upper surface and inner side of the main track, and the two slits form a clamping groove on the inner side of the main track. During assembly, insert the buckle into the slot and lock it. The upper surface of the main track and the upper surface of the reversing track are just on the same horizontal plane, and the inner side of the main track and the upper end face of the reversing track form a guide gap. The four-way shuttle car structure is more convenient for disassembly and maintenance. When the component structure is damaged, it does not need to be disassembled as a whole, just replace a single reversing track.

HEGERLS – Four way shuttle track system

The four-way shuttle car track system mentioned here is the track system of the track reversing component of the four-way shuttle car, which includes a number of track reversing components and a number of sub track systems corresponding to the track reversing component. Multiple track reversing components are arranged and connected in turn along the extension direction of the main track to form a track reversing system. When the four-way shuttle car runs on the main track of the track reversing system, it can selectively realize reversing on any track reversing component as required. At least one side of each track reversing component is connected with a sub track system, that is, a sub track system can be connected outside one main track, or the sub track system can be connected outside two main tracks. The sub track system includes two sub tracks set on the outer side of the main track and multiple pairs of sub track support devices supporting the two sub tracks, which extend on the extension line of the two reversing tracks respectively. The sub track has a track support surface and a cargo placement surface. The track support surface and the upper surface of the main track are on the same horizontal plane. The cargo placement surface is located above the track support surface for cargo placement. The four-way shuttle car reverses and runs to the sub track system on the track reversing component to realize the cargo access on the sub track system.

Post time: Dec-21-2022