In recent years, facing the increasing demand for services with multiple varieties, small batches, and customized products, the problems of low utilization of storage capacity, low sorting efficiency, and inability to respond quickly in the manufacturing industry have become more prominent! Hebei Woke HEGERLS has been deeply involved in the field of intelligent warehousing and logistics for many years, serving over 50+industries. Regarding the manufacturing industry, let’s talk about the application of the “Box Type Four Way Shuttle” project created by Hebei Woke HEGERLS for a certain enterprise user in the manufacturing industry.

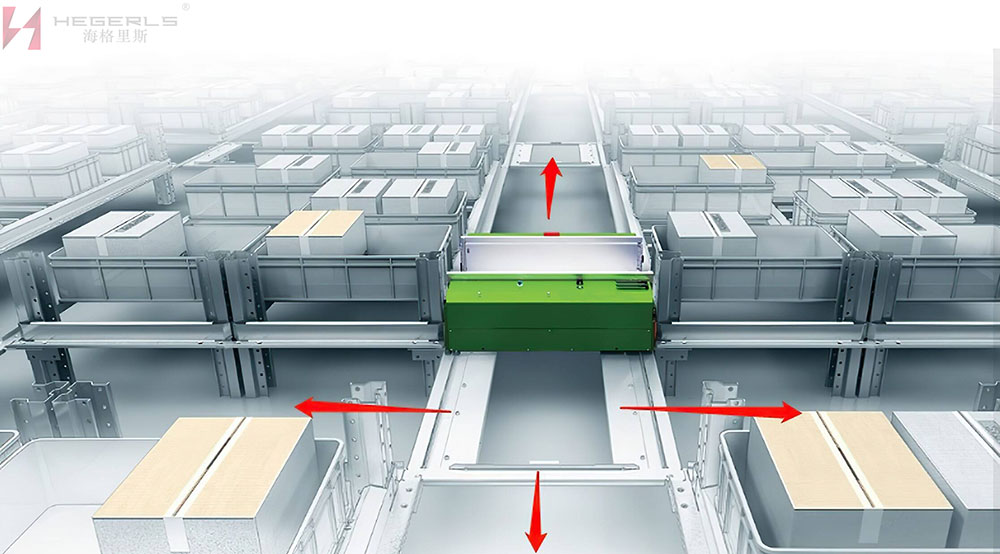

Description of HEGERLS Box Type Four Way Shuttle Vehicle Shelf Scheme

In this solution, a box type four-way shuttle truck rack is used, and some of its equipment includes: 1 box type four-way shuttle truck rack (carrying capacity: 30KG/box; number of cargo spaces: 14030; including back net, safety guardrail, maintenance channel, ladder, etc.), 68 sets of rack end conveyors (conveying speed: 30M/MIN), 7 box type four-way shuttle trucks, and 2 vertical layer changing conveyors (used for layer changing operations on shuttle trucks and material boxes), 1 set of material box conveying line in front of the warehouse (conveying speed: 30M/MIN), 1 set of warehouse management system (WMS warehouse management system), 1 set of warehouse monitoring system (WCS warehouse monitoring system), and 1 set of warehouse monitoring system (WCS warehouse monitoring system). In emergency situations, the warehouse can be operated through the WCS management system or on-site ECS operation screen (requiring additional input of input and output information), and we are committed to building the warehouse into an integrated information system A comprehensive intelligent warehouse that integrates automation and intelligence.

Job ability

The Hebei Woke HEGERLS box type four way shuttle vehicle in the project has multiple functions such as remote control, self testing of battery level, prompt alarm, online charging, remote updating and downloading of programs, self measuring shelves, inputting parameters, communication data transmission, log recording, etc. The cycle operating efficiency of a single box type four-way shuttle car is 45 boxes/hour. The overall operational efficiency of 7 box type four-way shuttle cars is 40 * 7=280 boxes/hour (outbound+inbound), and the composite operational efficiency can reach 45 * 7=315 boxes/hour (outbound+inbound).

Under the unified scheduling and management of the WMS management system, logistics equipment such as four-way shuttle cars, high-speed elevators, box conveyor lines, AGVs, etc. are each responsible for providing timely and efficient delivery services and receiving and shipping services for the final assembly line and finished product warehouse. This system has changed the inefficient method of mainly using manpower and forklifts for material handling, greatly improving production efficiency, achieving automation of receiving and sending operations, digitization of warehouse management, three-dimensional storage units, information transmission network grids, and visualization of safety monitoring.

Realizing Value of Solutions

1) Optimize the workflow, achieve precision and efficiency

The HEGERLS box type four-way shuttle system can seamlessly interface with the WMS/WCS system, allowing real-time collection of key information such as material information, equipment information, and task information. All item link data can be traced for later analysis, making it easy for production management. Through the system monitoring interface, you can directly grasp the current status and task information of the HEGERLS box type four-way shuttle, and also see the information status of each docking link. Accurate tracking and management of item positions can effectively improve inbound and outbound management, achieving the demand for large-scale, long-distance, high-speed, and high-precision intelligent logistics.

2) Automated handling is more intelligent, safe, and efficient

Compared with traditional production lines, using a box type four-way shuttle intelligent logistics handling system can reduce labor by 50%, greatly reducing labor costs. At the same time, under the control of the scheduling system, the box type four-way shuttle can reach any location in the warehouse, fully utilizing the warehouse space, and solving the problem of low efficiency caused by physical energy consumption.

Today, the Hierarchies system brought by HEGERLS, Hebei Woke, has successfully built a number of landing projects at home and abroad, covering power, new energy, catering, home furnishing, third-party logistics, automobile, medical, electronics, aerospace, coal mine, new materials, agriculture, education and other industries. With the advantages of flexibility and scalability, Hierarchies has realized efficient and intensive storage and warehousing solutions for users in different industries. In the wave of digital intelligent storage reform at home and abroad, Hebei Woke HEGERLS, as a high-quality representative of domestic four-way shuttle manufacturers, is playing an increasingly important role. With its core technology, traditional enterprises can also complete Digital transformation more efficiently and thoroughly.

Post time: Apr-25-2023