Heavy storage shelves, also known as cross beam shelves, or cargo space shelves, belong to pallet shelves, which is the most common form of shelves in various domestic storage shelf systems. The fully assembled structure in the form of column piece + beam is concise and effective. Functional accessories such as partition, steel laminate (wood laminate), wire mesh layer, storage cage guide rail, oil tank rack, etc. can be added according to the characteristics of the container equipment in the storage unit. Meet the storage of goods in the form of different unit containerized equipment. So when individual enterprises have to use heavy shelves to standard warehouses, what aspects should be considered? Now, Hergels storage shelf manufacturer will introduce it to you.

The existence of heavy storage shelves greatly meets the access needs of different warehouses, different goods and different storage conditions. Of course, it also improves the efficiency of logistics and warehousing as a whole, and provides the necessary conditions for the standardized and efficient operation of enterprises. The structures of heavy storage shelves are different, the actual operation effects are different, and the purchase costs are also very different. Enterprises need to choose targeted design and manufacturing according to the specific storage conditions, integrate various factors and the suggestions of storage shelf manufacturers.

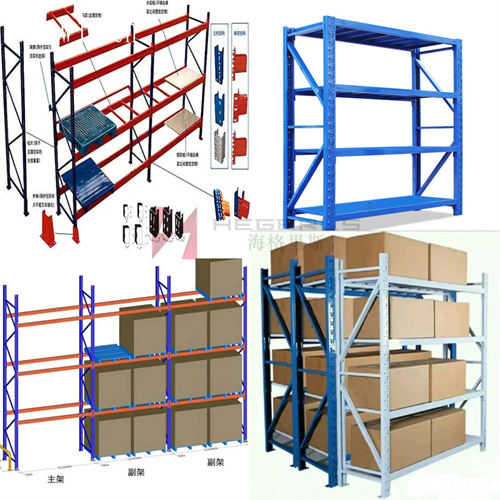

Heavy storage shelf structure

The heavy shelf is assembled by columns, beams, cross braces, diagonal braces and self-locking bolts, which can effectively prevent the instability of the shelf caused by the loosening of bolts; The beam adopts special cold-rolled P-shaped closed beam; The structure has the characteristics of simple and reliable, light weight, strong bearing capacity and low cost; When the column clamp is connected with the column, it is equipped with a specially designed safety pin, which can ensure that the beam will not fall off under the impact of external force; The laminate adopts the internationally made strip laminate, which has the characteristics of strong bearing capacity, wear resistance, simple replacement and low maintenance cost.

Heavy storage shelf design

First of all, it is necessary to carry out the unitization work, that is, the packaging of goods and their weight and other characteristics, and determine the type, specification, size, single support load weight and stacking height of the pallet (the weight of single support goods is generally within 2000kg), and then determine the span, depth and layer spacing of the unit shelf, and determine the height of the shelf according to the effective height of the lower edge of the warehouse roof truss and the maximum fork height of the forklift truck. The span of unit shelves is generally within 4m, the depth is within 1.5m, the height of low and high-level warehouses is generally within 12M, and the height of super high-level warehouses is generally within 30m (such warehouses are basically automated warehouses, and the total height of shelves is composed of several sections of columns within 12m).

Heavy storage rack auxiliary equipment

In such warehouses, low and high-level warehouses mostly use forward moving battery forklifts, balance weight battery forklifts, and three-way forklifts for access operations. When the shelves are low, electric stackers can also be used, and super high-level warehouses use stackers for access operations. This kind of shelf system has high space utilization rate, flexible and convenient access, supplemented by computer management or control, and can basically meet the requirements of modern logistics system. It is widely used in manufacturing, third-party logistics, distribution centers and other fields. It is not only suitable for multi variety and small batch goods, but also suitable for small variety and large batch goods. Such shelves are most used in high-level warehouses and super high-level warehouses (such shelves are mostly used in automated warehouses).

So when individual enterprises have to use heavy shelves to standard warehouses, what aspects should be considered?

net weight of goods and pallets

The goods on the heavy storage shelves are generally placed on the storage shelves with pallets to facilitate the transportation and storage of goods with electric forklifts and other equipment. Therefore, the total weight of pallets and goods is an important link for the design staff to calculate the required load-bearing of each layer of the storage shelves. Only by accurately determining the load-bearing of the storage shelves can the safety factor of the storage shelves be ensured.

tray size and product specification

According to the different stored goods, the selected pallets will also have certain differences. For example, the total area of the pallets will exceed the total area of the goods, and the total area of the goods will exceed the total area of the pallets. At this time, the design staff must calculate the length, width and height of each layer of storage shelves according to the total area of the two, so as to ensure the convenience of the application of storage shelves.

The net height width ratio of the warehouse and its electric forklift improve the height width ratio

The height width ratio of each layer can be determined according to the height width ratio of the goods plus towing tray, but if the indoor space of the warehouse is insufficient, or the height width ratio of the electric forklift is insufficient, the top storage shelf will be unusable. Therefore, it is very necessary for the design scheme staff to master the height of the warehouse and the height width ratio of the electric forklift.

Model, specification and main parameters of electric forklift

In the heavy-duty storage rack warehouse, it is necessary to reserve a safe passage for equipment and facilities such as electric forklifts with sufficient width, and to supply power to the operation requirements of equipment such as electric forklifts. Different electric forklifts are also different in operation, so it stipulates that the designer must master the model, specification and main parameters of equipment such as electric forklifts, so as to design a reasonable solution for heavy-duty storage racks in the warehouse.

engineering and building conditions in the storage area

In different warehouses, the structures of fire hydrants, fire access doors, engineering building poles, doors, non motor vehicle safety passages and so on can not be exactly the same. For this, only by mastering the site conditions first, can we effectively and reasonably allocate the sorting mode of storage shelves, so as to improve the utilization rate of indoor space in the warehouse and ensure the maximization of customer value and profit.

A sound plan and design of heavy-duty shelf warehouse should consider all-round multiple elements, and integrate the specific application requirements of customers, so that the feasibility analysis and applicability of the plan can be achieved. Hagerls storage shelf manufacturer is one of the professional manufacturers specializing in the planning, design, manufacturing and installation of various shelves and logistics systems. Our company has strong technical force, integrated production equipment, mature installation team and perfect after-sales service system. Our company operates in strict accordance with industry norms, constantly absorbs advanced technologies of domestic and foreign logistics systems, and constantly develops new products in combination with the actual situation of domestic and foreign enterprises. The company selects high-quality raw materials and is committed to all kinds of adjustable and assembled heavy pallet shelves, through shelves, shuttle shelves, cantilever shelves, attic platforms, heavy shelf storage, storage shelves heavy, attic platform shelves, heavy shelf warehouses, heavy warehouse shelves, beam storage shelves, attic storage shelves, warehouse attic shelves, cantilever shelves, gravity shelves, laminate shelves, medium and secondary heavy shelves Design, manufacture and installation of special shelves, roller shelves, laminated shelves and supporting equipment in automobile 4S stores; Not only that, recently, our company has also independently developed treasure box robot system, including treasure robot haipik, intelligent charging pile, customized goods storage device, multi-function workstation and haiq intelligent management platform, to help warehouse automation management. Kubao robot system includes: Carton picking robot herls a42n, lifting picking robot herls A3, double deep bin robot herls a42d, telescopic lifting bin robot herls a42t, laser slam multi-layer bin robot herls a42m slam, multi-layer bin machine human herls A42, dynamic width adjusting bin robot herls a42-fw. Kubao robot has the functions of intelligent picking and handling, autonomous navigation, active obstacle avoidance and automatic charging. It has the characteristics of high stability and high-precision operation. It can replace repeated, time-consuming and heavy manual access and handling work, realize efficient and intelligent “goods to people” picking, and greatly improve the storage density and manual efficiency of the warehouse. The storage shelves, storage equipment and intelligent storage robots produced by Hergels are widely used in manufacturing, logistics and storage, medicine, storage supermarkets, libraries and other industries. The products and services cover nearly 30 provinces and autonomous regions in China. The products are exported to Europe, America, the Middle East, Latin America, Southeast Asia and other countries and regions, and have made remarkable achievements overseas, In particular, the overall planning and design equipment integration of the three-dimensional warehouse project and the logistics park.

Post time: Aug-04-2022