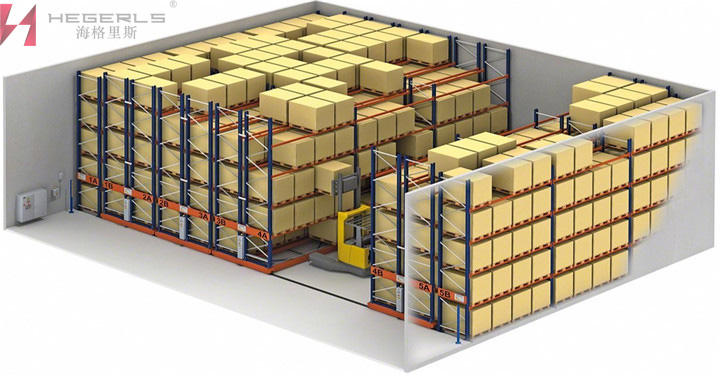

The electric mobile shelf system is one of the high-density storage shelf systems. The system only needs one channel and the space utilization rate is high. It is suitable for warehouses with high cost per unit area, such as cold storage shelves, explosion-proof storage shelves, etc. The load-bearing trolley is driven by the motor, and the cross beam rack is placed on the trolley for frequency conversion speed regulation. The rack is extremely balanced from start to braking, and the performance is guaranteed. This kind of rack has frequency conversion control function, which can control the speed when driving and stopping to prevent the goods on the rack from shaking, tilting or dumping. A photoelectric sensor for positioning and a brakable gear motor are also installed at the appropriate position, which improves the positioning performance.

The storage capacity of the electric mobile shelf is larger than that of the traditional fixed storage shelf. The storage capacity can be twice as large as that of the traditional pallet shelf, saving the warehouse space, and the ground utilization rate is 80%. It is suitable for the storage of goods with less samples, more quantities and low frequencies. It is convenient to access each item of goods without being affected by the storage order of goods. It can be controlled by computer, with simple operation and convenient inventory management.

Key points of scheme design for electric mobile shelf

1) A minimum of 500mm working space shall be reserved on the side near the wall;

2) The column in the building does not affect the movement of the shelves at both ends of the column, and mature technology is available to ensure the synchronous movement of the two shelves;

3) The crossbeam layer at the bottom of the electric mobile rack shall be designed with a grid or steel or grid plate;

4) Fixed frames shall be designed at both ends as far as possible;

Electric mobile rack rack and equipment parameter requirements

◇ main materials and specifications of electric moving rack

The column is made of high-quality Q235 steel, with a “Ω” section structure with a section size of 90 * 67 * 2.0, and the beam is made of 100 * 50 * 1.5 clasp beam. The continuous hole distance of the column is arranged in a straight line with a distance of 50mm. The column hole is used to hang the beam and the laminate, and can be adjusted up and down by 50mm for easy disassembly and assembly;

◇ description of mechanical structure scheme of electric moving rack

1) The rack column piece is an assembled structure, which is composed of several cross braces, diagonal braces and columns connected and assembled by high-strength bolts. The rack column piece and the mobile base are connected by bolts;

2) The crossbeam and the column piece are connected by double inclined front locking 3-claw plug-in connection, and equipped with safety pins, which can effectively prevent accidents such as forking off the crossbeam due to forklift operation errors;

3) The two rows of adjacent back-to-back shelves are connected by spacers in the height direction to strengthen the overall stability of the two rows of shelves;

4) All beams are laid with steel laminates, and the trays are placed flush with the beams. Galvanized mesh can be installed on the back of the shelf to prevent potential dangers caused by pallet offset or small goods falling and ensure safety;

5) The wheels are made of special die steel, with a service life of more than 5 years;

6) The chassis is made of 4.5mm high-quality steel plate, which is bent and formed through self-developed open mold manufacturing. The positioning holes such as the axle are accurate, with strong bearing capacity and beautiful appearance;

7) Each layer is laid with steel layer mesh, 50 * 100 * 5.0mm, 2 bars per layer, 2 pieces / layer;

8) The number of shelves is designed to be 3000.

◇ functional description of electric moving rack equipment

1) Equipment operation method: the electric mobile rack system controls the upward and downward movement of the rack unit through the manual operation button on the panel of the control box of the sub control unit. The movement is in the inching control mode, that is, after pressing the corresponding button of the channel to be opened, the movement will start with the buzzer prompt and stop automatically after it is in place. (haigris reminded: the shelf spacing should be kept about 110mm)

2) Equipment indication function: each electric mobile shelf unit provides various indication information such as operation buzzer warning, operation indication and fault alarm.

3) Equipment emergency stop and fault alarm function: the field unit control box has emergency stop operation function. When the emergency stop button of the unit control box is pressed, the unit moving rack stops running; After the emergency is relieved, the system can work normally only after the fault is confirmed.

◇ composition and configuration of electric moving rack system

1) The electronic control equipment of equipment control layer is composed of unit control box, power distribution line and operation detection device. Field unit remote control box: according to the layout of the electric mobile rack on site, the rack can be divided into 3 units. Each mobile rack unit is equipped with a control box. The drive frequency converter and control circuit are configured in the box to complete the functions of inching continuous movement and maintaining a fixed rack spacing.

2) The unit shelf is controlled by a frequency converter to make the movement of the shelf smooth and impact free and avoid shaking during operation. The movement and positioning functions are completed by collecting the detection element signals (such as photoelectric switches) on the field equipment and controlling the process actuators (such as contactors, indicator lights, etc.).

◇ electric moving rack power and control voltage parameters

The power distribution of the control layer of the electric mobile shelf equipment adopts two-level power supply mode, namely, the low-voltage power distribution of the workshop to the power distribution device of the electric control system, the power distribution from the power distribution device to the unit field control box, and the power supply from the field control box to the equipment motor. Each level of power transmission adopts protection switch to protect the next level of equipment.

◇ power supply requirements for electric moving rack

1) Power supply: 400VAC ± 10%, 50Hz ± 1Hz, three-phase five wire system; AC380 / 400V (50 / 60Hz) 0.4KW, two / train, three-phase five wire system;

2) Auxiliary power supply: 220VAC ± 10%, 50Hz ± 1Hz, single-phase two-wire system;

3) Voltage level of button and indicator lamp: 24VDC;

4) The voltage level of the detection device is 24VDC;

◇ electric moving rack guide rail embedded

The electric mobile rack needs to be embedded with guide rails, which are specially made for Party B, so the installation needs to be carried out according to the site civil engineering conditions.

Hegerls electric mobile shelf quotation: before quotation and quotation, our company needs to know the specific actual data of the warehouses of major enterprises before quotation and quotation. For example:

1) CAD building drawings of the warehouse, or dimensional data of the warehouse measured on site.

2) Pallet size, fork direction, pallet width, depth and height data.

3) Load data for each pallet.

4) Available net height data of the warehouse.

5) Models of all forklifts, or working channels required by forklifts, with large lifting height.

6) Internal logistics process of warehouse.

Post time: Aug-19-2022