With the development of e-commerce industry, the market requires faster distribution and logistics speed. At the same time, the rise in labor prices makes the value of the “goods to people” system reassessed. The market gradually finds that the “goods to people” system can alleviate the pressure of warehousing and logistics. So far, there have been new changes in the process of warehousing automation: from traditional manual warehousing to mechanized warehousing using conveyor belts, transport vehicles, etc., to integrated automatic warehousing. Nowadays, the application of artificial intelligence and algorithms has officially entered a new stage of warehousing automation. Hercules hegerls is well aware that building automated warehousing requires the integration of various logistics equipment and technologies. Recently, the kubao system developed by hegerls shows the seamless docking function from transmission to storage to sorting in the warehousing scenario. At the same time, the perfect cooperation between kubao system and robot arm can also make the storage integration ability of kubao system more visible. So what is a fully automatic unmanned storage manipulator? What kind of dominant position does it occupy in the storage of goods?  Hercules Hegels has dug deep into the pain points of users, grasped the new needs of the market, and continuously developed innovative solutions suitable for different scenarios. In terms of human-computer interaction, hagerls has its own unique understanding, and has designed several human-computer interaction modes and schemes, including automatic loader workstation, human-computer direct sorting workstation, conveyor line workstation, cache shelf workstation, and manipulator workstation. The specific classification is as follows: First, man-machine direct picking workstation In the man-machine direct sorting workstation, the operator can sort directly on the basket of the machine, and the sorting can be completed only by configuring a workstation and a scanning gun. Second, transmission line workstation The robot connects with the conveyor line. The robot puts the material box on the basket on the conveyor line, and the conveyor line sends the material box to people in front of them. People directly pick in the material box, which greatly improves the operator’s picking comfort and avoids safety problems. Third, cache shelf workstation The robot puts the material box on the cache shelf, and people do picking on the shelf. Robots are released and go, liberating efficiency. Fourth, automatic loader workstation In order to give full play to the human-computer efficiency synergy, haggis hegerls invented the automatic loading and unloading machine, which once again subverted the way of goods to people interaction. Combined with the efficient multi container handling characteristics of kubao, it realized the loading and unloading of multiple containers, and greatly improved the efficiency of warehousing and warehousing. The automatic loading and unloading machine is specially designed for the box storage robot system, further innovating the interaction mode between goods and people, enriching the types of workstations in the warehouse system, and improving the efficiency of warehouse operations.

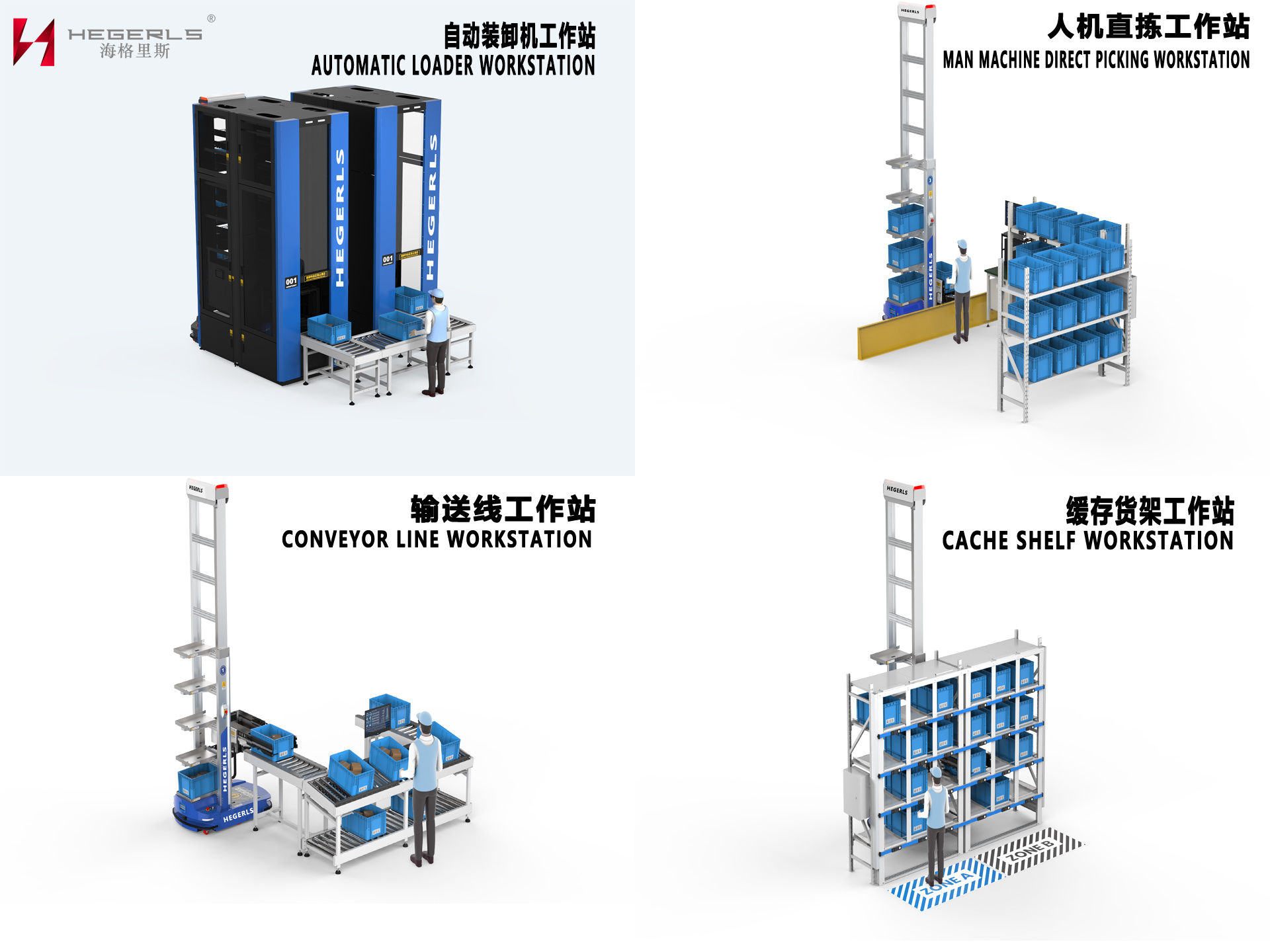

Hercules Hegels has dug deep into the pain points of users, grasped the new needs of the market, and continuously developed innovative solutions suitable for different scenarios. In terms of human-computer interaction, hagerls has its own unique understanding, and has designed several human-computer interaction modes and schemes, including automatic loader workstation, human-computer direct sorting workstation, conveyor line workstation, cache shelf workstation, and manipulator workstation. The specific classification is as follows: First, man-machine direct picking workstation In the man-machine direct sorting workstation, the operator can sort directly on the basket of the machine, and the sorting can be completed only by configuring a workstation and a scanning gun. Second, transmission line workstation The robot connects with the conveyor line. The robot puts the material box on the basket on the conveyor line, and the conveyor line sends the material box to people in front of them. People directly pick in the material box, which greatly improves the operator’s picking comfort and avoids safety problems. Third, cache shelf workstation The robot puts the material box on the cache shelf, and people do picking on the shelf. Robots are released and go, liberating efficiency. Fourth, automatic loader workstation In order to give full play to the human-computer efficiency synergy, haggis hegerls invented the automatic loading and unloading machine, which once again subverted the way of goods to people interaction. Combined with the efficient multi container handling characteristics of kubao, it realized the loading and unloading of multiple containers, and greatly improved the efficiency of warehousing and warehousing. The automatic loading and unloading machine is specially designed for the box storage robot system, further innovating the interaction mode between goods and people, enriching the types of workstations in the warehouse system, and improving the efficiency of warehouse operations.

In the later stage, hegerls also developed hegerls manipulator, namely hegerls fully automatic unmanned storage manipulator workstation, which is mainly realized by the manipulator instead of manual, docking with the conveyor line workstation or automatic loader workstation. The conveying line or automatic loading and unloading machine is connected with kubao series robots to automatically convey the unloaded material boxes or the material boxes that need to be loaded. The mechanical arm replaces the workers to sort the order goods, and realizes the full-automatic unmanned warehousing process. It has the advantages of intelligent automation, zero labor cost, efficient warehousing and warehousing. Kubao realizes intelligent storage and handling in the reservoir area, docking the mechanical arm, intelligent sorting of small goods by the mechanical arm, and the delivery and warehousing process is completed by the conveyor line. The sorting process of the manual operation platform is omitted, and the whole process of unmanned operation is applicable to a variety of application scenarios, including goods arrival and production manufacturing. Applicable scenario: it is especially applicable to the picking scenario of supermarket retail items。

Functional characteristics of hagerls fully automatic unmanned storage manipulator workstation Liberate labor – realize fully automatic and unmanned warehousing, replace workers to sort goods, and realize fully automated warehousing and warehousing; Intelligent sorting – haiq intelligent management platform system seamlessly connects with the manipulator motion control system, and directly sends instructions to guide the manipulator to sort goods; Flexible docking – docking with kubao robots, conveyor lines, cache shelves or automatic loading and unloading machines to meet the needs of different business scenarios; Efficient warehousing and egress – each robot carries 25-35 boxes out / hour +25-35 boxes in / hour, and the warehousing and egress efficiency can reach up to 300 boxes / hour.

Hagerls focuses on the R & D and design of intelligent warehousing robot system, and is committed to reducing costs and increasing efficiency for customers through robot technology and artificial intelligence algorithm, so as to create an efficient, intelligent and flexible intelligent warehousing system. The recognition of the market and customers will become the driving force for the continuous progress of Hegels. Hagerls will be deeply engaged in innovation and R & D, focusing on the R & D and design of intelligent storage robot system. At the same time, it will develop a wider range of application scenarios to solve customers’ storage pain points and meet customers’ storage needs. Robots and artificial intelligence technology are ushering in a golden age of development, with opportunities and challenges coexisting. In the future, hagerls will adhere to technological innovation and breakthroughs, focus on the segmentation of box storage robots, and gradually optimize the product and function matrix based on the customer storage pain points, so as to further lead the development and progress of the segmentation industry.

Post time: Jul-08-2022