In recent years, with the increasing shortage of land resources and increasing human costs, the automation upgrading of the warehousing and logistics industry has always taken “reducing costs and improving efficiency” as the top priority. In recent years, warehousing and logistics automation equipment has emerged in endlessly, but warehouse operators always have a pain point: it is difficult to give consideration to efficiency and cost. In view of this pain point, the hegerls team of hegris, which can reduce the deployment of robots by 30%, reduce labor costs by 66%, and improve the sorting efficiency by 3-4 times, is deeply involved in the field of box storage robot system. It specializes in hegerls automatic loading and unloading machines for kubao robot, defines a new interaction mode between goods and people, and further improves the storage efficiency. Higgins hegerls automatic loading and unloading machine workstation once again subverts the interactive mode of goods to people, and combines the efficient multi container handling characteristics of kubao to realize multi container loading and unloading, greatly improving the efficiency of warehousing and warehousing.

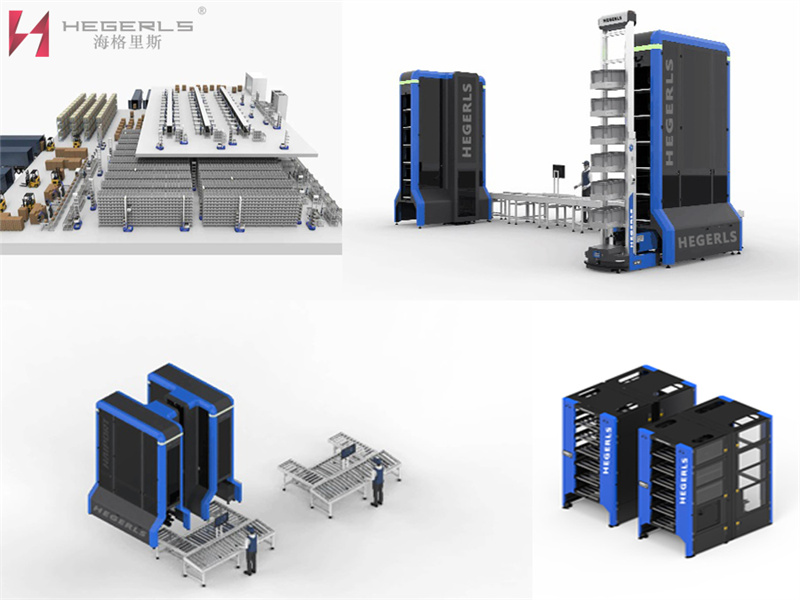

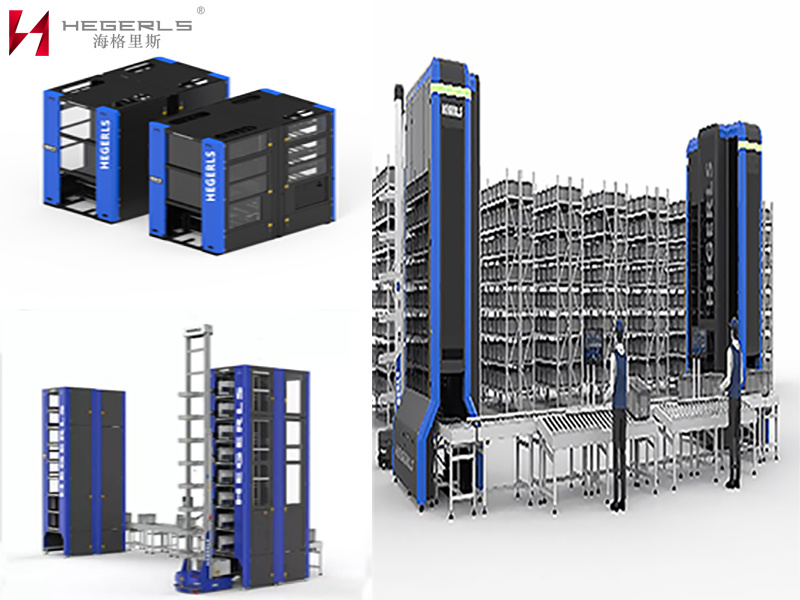

The hegerls automatic loading and unloading machine workstation is composed of an automatic loading and unloading machine, a conveying line, a visual Kanban, a seeding wall, and a light sorting system. It is connected with kubao series robots to automatically unload, convey, and load the material box from the robot’s back basket, so as to realize a more automatic warehousing and unloading function. The workstation has a more efficient loading and unloading efficiency, which can complete the loading of 6 containers in 3S and the unloading of 6 containers in 5S, greatly improving the efficiency of the robot; Modular design, flexible and easy to move, support rapid increase / decrease of equipment, and meet the needs of efficiency and cost; Workers are separated from robots to ensure safety; According to the ergonomic design, the picking console has the advantages of humanization, convenient operation, high efficiency in and out of storage, etc. Applicable scenario: the whole scenario is applicable, especially for the scenario with a large number of stored materials and picking.v

Design principles of hegerls automatic loading and unloading machine workstation:

As a product with ETL and CE certification, haggis automatic loading and unloading machine has passed strict tests in terms of mechanical safety, electrical safety, functional safety, fire safety, occupational safety and health, ensuring the reliability of the product;

*Safety functions are based on the design principles of standard ISO 12100 to minimize risks;

*The control system is designed and manufactured in accordance with the requirements of iec/en 60204-1 and ISO 13849-1, and the safety devices (interlock switch, emergency stop) are monitored by safety relays and operate only under safe conditions. The safety performance level reaches PL D;

*The design of the control panel and workbench conforms to ergonomics;

*HMI (human machine interface) human-machine interface is integrated on the electric cabinet and located outside the dangerous area to prevent any foreseeable danger;

*The whole machine door of the equipment is equipped with an interlock protection device, and the door opening motor is powered off. The machine can resume operation only after the whole machine door is normally closed. The safety of maintenance personnel is guaranteed to the greatest extent, and the safety risk is greatly reduced;

*The lifting system is designed to withstand a single fault and is protected against related risks by closed fixed cover plates and interlocking protection devices;

*Key safety devices shall be compliant devices that meet the requirements of American and European standards.

Working principle of hegerls automatic loader workstation:

The containers are picked and handled by kubao robot, which is connected with the hegerls automatic loader workstation. The unloading of multiple containers is realized in 5S, and the containers are returned to the hegerls automatic loader workstation after sorting. The containers are loaded in 3S, showing an efficient warehousing and warehousing process. The hegerls automatic loading and unloading machine workstation also supports the docking with the manipulator to realize the sorting of goods, create the automation of the whole process of inbound and outbound, and further improve the efficiency of warehousing operations.

Functional characteristics of hegerls automatic loader workstation:

*Efficient and fast – loading speed 3S, unloading speed 5S

The hagerls automatic loading and unloading machine workstation is specially developed and designed for kubao robot. The two are connected intelligently to realize the loading and unloading of multiple containers. Each robot can complete the loading of 6-8 containers at one time in only 3 seconds and the unloading in 5 seconds. Compared with the conveyor line workstation, the loading and unloading speed of the robot is 16 times higher.

*Cost reduction and efficiency increase – improve the working efficiency of a single robot by 30%

The intelligent storage solution based on kubao robot can increase the storage density by 80% – 130% and improve the working efficiency of the warehouse by 3-4 times. In cooperation with the hagerls automatic loading and unloading machine workstation, kubao robot can automatically load and unload containers, realize loading (unloading) and walking, and the efficiency of the robot can be increased by 30%. Within the same time unit, the robot can complete more order tasks, achieve a 30% improvement in system efficiency, and the warehouse is more efficient.

*Flexible adaptation business scenario – flexible mobility, rapid change of installation location, strong scalability

The hagerls automatic loader workstation adopts modular design and supports the docking of a full range of kubao robots. The customized version of the hagerls automatic loader workstation can load / unload up to 8 containers at the same time. The hegerls automatic loading and unloading machine workstation can flexibly change its location, and flexibly change the number of workstations and consoles based on business conditions, which is closer to business scenarios.

*Effectively reduce the cost of Automated Deployment

The perfect cooperation between Kubo robot and hegerls automatic loading and unloading machine workstation can effectively reduce the deployment cost of warehousing automation. Under the same conditions, the configuration of hegerls automatic loading and unloading machine workstation can reduce the number of robots, improve the efficiency of warehousing and unloading, and effectively reduce the cost of warehouse reconstruction.

*Safer container to person mode

The efficient “container to person” provided by the hegerls automatic loading and unloading machine workstation has created a new way of cargo to person interaction. The design of hegerls automatic loader workstation conforms to ergonomics and improves the comfort of manual operation. The goods can be picked manually at the designated position of the operation platform to avoid direct contact with the robot and ensure the safety of operation.

*Flexible docking of various devices

For different use scenarios, the hegerls automatic loader workstation supports flexible docking of a variety of equipment: the hegerls automatic loader workstation can be configured with multiple manual operation positions to complete cargo sorting and further improve the efficiency of “container to person”; It can also be connected with mechanical arms and other equipment to realize automatic sorting and improve operation efficiency.

*Friendly human-computer interaction – 900 boxes / hour warehousing efficiency, improving the efficiency of manual picking by 2-3 times;

According to the specific business needs, haggis provides customized scheme design. Using the hegerls automatic loading and unloading machine workstation, the warehousing efficiency can be as high as 900 boxes / hour, which greatly improves the work efficiency and improves the manual picking efficiency by 2-3 times.

Post time: Jul-08-2022