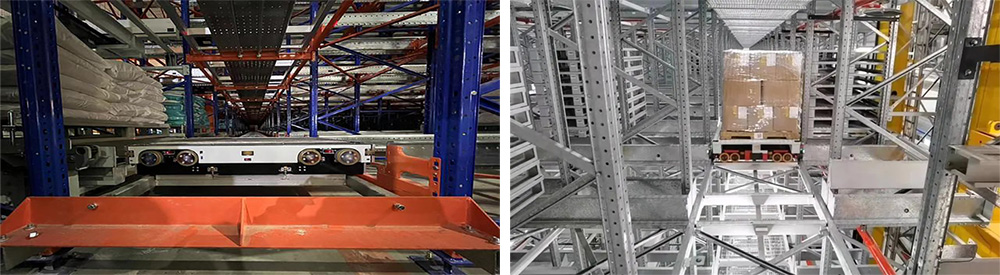

With the rapid development of warehousing, logistics, and e-commerce industries, the technology of automated warehouse equipment is constantly improving. The “goods to people” picking technology is increasingly valued by the industry and has gradually become a focus of attention for both supply and demand sides. The “goods to people” picking system mainly consists of several major parts, including storage system, replenishment system, conveying system, picking system, and packaging system. Each subsystem has its own characteristics, among which the storage system is the most critical. There are various types of storage systems, such as four-way shuttle systems, multi-layer shuttle systems, rotating shelf systems, etc. Among them, four-way shuttle systems are most favored by users of large, medium and small enterprises.

Hebei Woke focuses on providing logistics robots and one-stop logistics overall solutions. With years of logistics experience and technical accumulation, Hebei Woke has expanded its technology to multiple logistics scenarios such as access, handling, and sorting in its independently developed Hegerls brand. Its product line covers multi-layer shuttle cars, tray/box four-way shuttle cars, tray/box two-way shuttle cars, shuttle cars, and parent-child shuttle cars Core high-end logistics equipment such as shuttle boards, pallet/box stackers, high-speed elevators, AGVs, dismantling/palletizing picking robots, Kubao robots, conveyor sorting, etc., as well as logistics management software (WCS, WMS) independently developed by Hebei Woke, are used to build internal intelligent logistics systems. By utilizing artificial intelligence and 5G technology, we provide customers with consulting and planning, equipment manufacturing, software development, and more A comprehensive solution that integrates system integration and project implementation into an end-to-end, highly intelligent, flexible, reliable, and cost-effective solution. The product is widely used in multiple industries such as medical, e-commerce, clothing, books, rail transit, manufacturing, automotive, new energy, and semiconductor, with over a hundred implemented projects.

Access, handling, and sorting are common logistics functions, but they vary from industry to industry. For example, new energy batteries carry items ranging from 50 kilograms to 200 kilograms, while in the express delivery industry, they handle flat parts and envelopes. Therefore, in different scenarios, the technology, hardware, and software required for using robots vary. Based on the three scenarios of storage, transportation, and sorting, we create basic products and tailor them according to the characteristics of different industries. Each industry has a complete set of solutions.

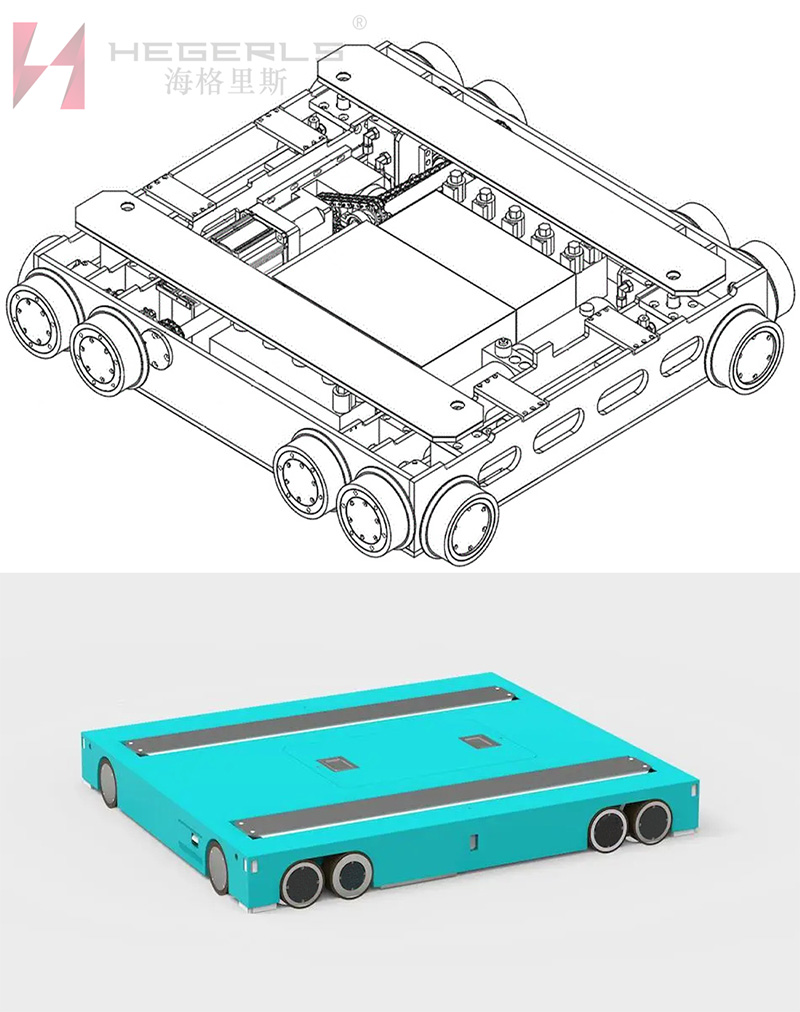

Hebei Woke takes the HEGERLS four-way shuttle as an example, insists on testing more than 1 million times, and optimizes and adjusts the design by analyzing the worn parts during testing; At the same time, in addition to the design of the vehicle itself, it is also necessary to consider the needs of different access environments, such as box size, storage density, vehicle scheduling and maintenance, etc. This has cultivated a complete set of abilities from software, electronic control, project integration, and after-sales, ultimately gaining the trust of customers.

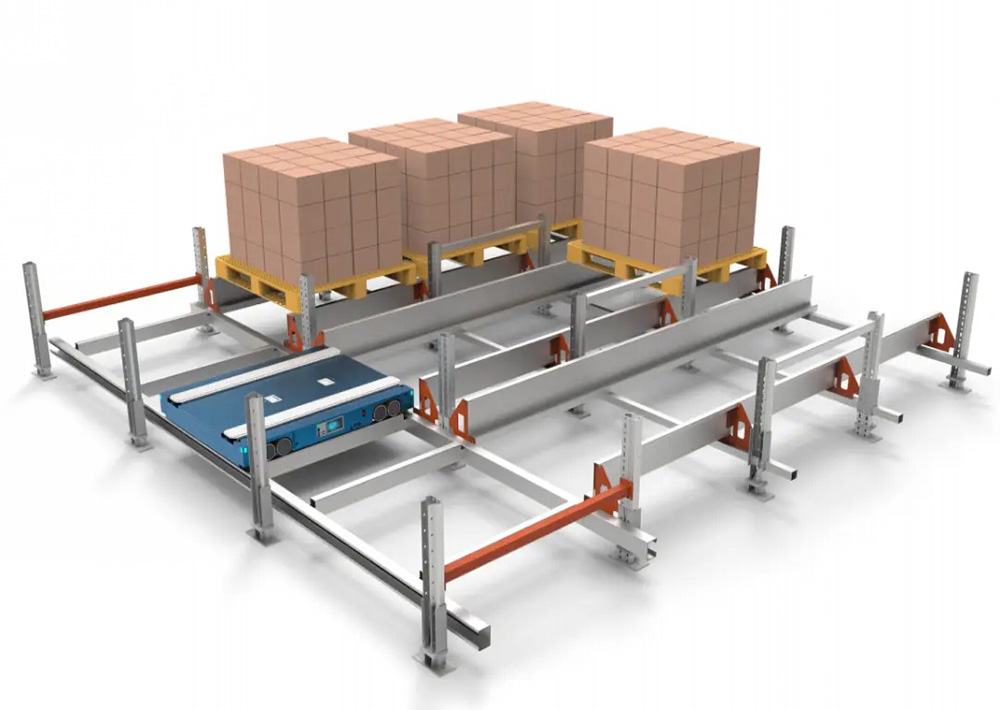

As an intelligent robot, the HEGERLS four-way shuttle can access, transport, and place palletized goods through shuttle boards, and can communicate with upper level systems or WMS systems. Combined with logistics information technologies such as RFID and barcode recognition, it achieves functions such as automated identification of goods, single access, and automatic sorting. The HEGERLS four-way shuttle realizes the “goods to people” picking system mode, improves storage and throughput capabilities, saves a lot of warehouse space, optimizes the enterprise supply chain, reduces warehouse operating costs, and elevates warehouse processing capacity to new heights. At present, a single HEGERLS four-way shuttle can achieve an access efficiency of up to 120 boxes/hour, and the combination of multiple HEGERLS four-way shuttle vehicles can achieve the superposition of processing capabilities, making customer business efficiency better than before and saving cost investment in logistics equipment. After the HEGERLS four-way shuttle truck lands in the user’s warehouse, compared to traditional above ground warehouses and forklifts (shelves+forklifts) warehouses, it can increase storage capacity by several times, greatly improving the production capacity of the storage space.

In addition to independently developing core logistics equipment, Hebei Woke has sufficient advantages in the core key software systems of logistics automation. From the underlying electrical control, operation scheduling, and logic control systems of the automation equipment system to the warehousing management system at the top level of logistics operation, all of them are independently developed and implemented by Hebei Woke, building a cross logistics equipment, automation integration, overall planning, and operation import system The ability to install, implement, and deliver solutions can provide customers with one-stop services for the construction of a full process logistics system.

Post time: Jan-18-2024