With the accelerated transformation and upgrading of domestic and foreign manufacturing industries, more and more enterprises need to upgrade their logistics intelligence, but they are often limited by practical conditions such as warehouse area, height, shape, and market uncertainty factors. Therefore, compared to investing in traditional automated three-dimensional warehouses, enterprises are more inclined to choose logistics systems with higher levels of intelligence and flexibility. The four-way shuttle system for pallets has become a favored automated and intensive storage system in the market due to its flexibility, intelligence, and other advantages.

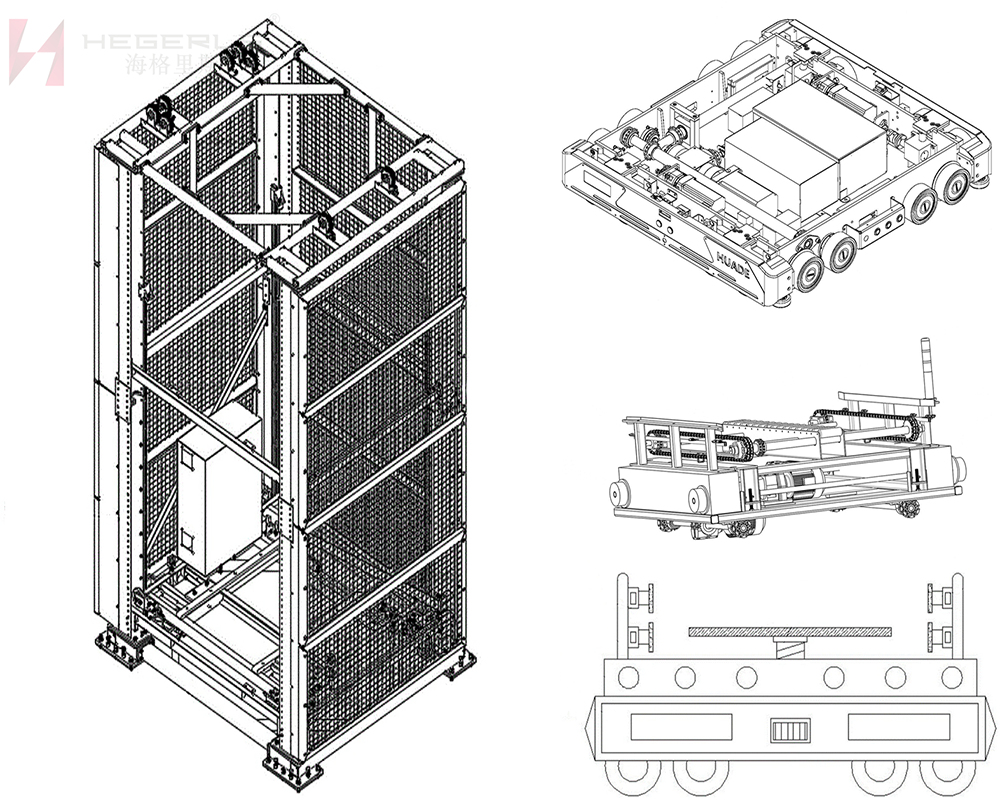

The pallet four-way shuttle is designed and improved on the structure of the two-way shuttle. The pallet two-way shuttle can achieve a “first in, first out” or “first in, first out” mode when picking up goods, and is mostly used in industries with large quantities and few varieties. But with the continuous development of the market, the demand for small and multiple batches is increasing. Meanwhile, due to factors such as land use and high labor costs, the demand for space utilization and intensive storage by enterprises is becoming increasingly urgent. In this context, tray four-way shuttle vehicles that can achieve dense storage, space utilization, and flexible scheduling have emerged. As one of the new intensive warehousing systems, the shelf monster is equipped with crisscrossing running tracks, and the pallet type four-way shuttle car ASRV can freely and flexibly cooperate with the elevator to achieve storage and picking of goods in any three-dimensional space.

As one of the earliest domestic enterprises to enter the research and development and production of shuttle car equipment, Hebei Woke Metal Products Co., Ltd. (independent brand: Hegerls) has been involved in the research and development of shuttle car products since 1998. So far, its shuttle car products have covered different series such as tray type shuttle mother car, box type two-way shuttle car, box type four-way shuttle car, tray type two-way shuttle car, tray type four-way shuttle car, attic type shuttle car, and so on. The tray four-way shuttle is one of the core products that Hebei Woke focuses on building. This type of equipment has high advantages in dense storage function, flexible expansion characteristics, and is suitable for operation modes with more product specifications and fewer batches.

The Higris intelligent tray four-way vehicle system is a flexible solution that revolves around tray storage and handling scenarios. Enterprise users can combine flexibility as needed, just like building blocks. At the same time, it can also achieve the function of “one vehicle running the entire warehouse”, and can adjust the number of vehicles according to changes in demand during off peak seasons and business growth. At present, the Hagrid tray four-way shuttle system has been implemented in some warehouses. According to actual measurement data from a raw material production enterprise, under the same warehouse area, using a stacker crane scheme can obtain 8000 storage spaces, while using a four-way vehicle scheme can obtain 10000 storage spaces, increasing space utilization by over 20%. Moreover, the Hagrid tray four-way shuttle also has the following advantages:

Firstly, strong adaptability: This is mainly reflected in the adaptability to the factory building. The application of traditional stacker cranes is generally in the construction of rectangular warehouses, while four-way shuttle cars can be built in a modular form even in irregular factories.

Secondly, the technology is very flexible and has excellent robustness: compared to traditional automatic stereoscopic warehouses that are limited by stackers, four-way vehicles are more flexible and can use multiple vehicles in a tunnel, thereby improving the entry and exit rate of the tunnel.

Thirdly, four-way shuttle cars are more energy-efficient and environmentally friendly: from the perspective of load capacity and self weight ratio, four-way shuttle cars have absolute advantages. Traditional stacker cranes weigh more than ten tons to pull one ton of goods, while four-way shuttle cars weigh several hundred kilograms and can also pull one ton of goods, resulting in lower energy consumption.

Fourthly, there is greater room for improvement in the future of four-way shuttle technology: in terms of vehicle scheduling and coordination between vehicles and elevators, based on optimization of artificial intelligence algorithms, there is further room for improvement in the unit time production capacity of each four-way shuttle in the future.

Meanwhile, most companies are also most concerned about the issue of speed. In terms of speed, the Hercules tray four-way shuttle can achieve a reversing speed of 2.5S in unloaded scenarios and 3.5S in loaded scenarios, which is a significant improvement compared to other products in the industry. For frequent start stop situations of four-way vehicles, Hagrid has also optimized the acceleration of the vehicle body, with an unloaded acceleration of up to 2m/s2.

The Hagrid four-way shuttle system can also be combined with other solutions such as autonomous mobile robots, palletizing robots, and visual inventory workstations. For example, in a clothing project, more than 80 four-way vehicles were used and can perform full box picking for over 10000 SKUs and tens of thousands of storage locations.

Post time: Feb-26-2024