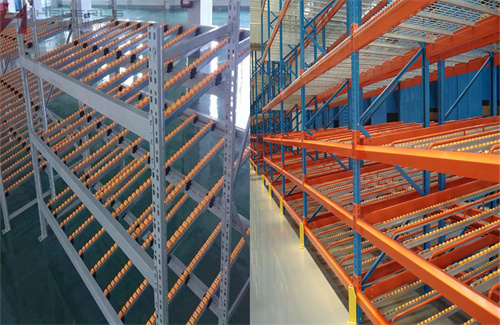

Fluent shelf, also known as sliding shelf, generally adopts roller type aluminum alloy or sheet metal fluent strip, which is placed at a certain slope (about 3 °). It is often evolved from the medium-sized beam type shelf. The goods are transported from the distribution end to the receiving end through the roller track. The goods slide automatically by gravity. The goods are usually packaged in paper or placed in the plastic turnover box. The goods flow and first in first out are realized by their own weight. The goods are transported by the trolley, and the manual access is convenient. The load capacity of each layer of the unit shelf is usually about 100kg, and the shelf height is within 2.5m, Place the product in several compartments. Low cost, high storage speed and high density. It is suitable for process conversion on both sides of the assembly line, assembly line production, picking operation in the distribution center and other places. It can be equipped with electronic labels to realize the information management of goods. It is widely used in automobile, medical, chemical and electronic industries.

Fluent shelf features

The fluency bar of fluency rack is directly connected to the front and rear crossbeams and the middle support beam, and the crossbeam is directly hung on the pillar. The installation inclination of fluency bar depends on the size and weight of the cargo box and the depth of fluency rack, usually 5% ~ 9%. The bearing capacity of fluency bar roller is 6kg / piece. When the goods are heavy, 3-4 fluency bars can be installed in one roller track. Generally, a support beam is installed every 0.6m in the depth direction to increase the rigidity of the fluent bar. When the raceway is long, a partition plate can be used to separate the raceway. The picking end shall be equipped with brake pads to decelerate the goods and reduce the impact.

Hegerls storage rack manufacturer

Hegerls storage shelf is one of the professional shelf manufacturers integrating R & D, design, manufacturing, installation, sales and consulting services. The company is mainly engaged in various shelves, logistics storage systems and various supporting storage metal products. Our products cover light, medium and heavy-duty shelves, beam type shelves, cantilever type shelves, attic type shelves, fluent type shelves, automatic storage three-dimensional warehouses, shuttle type shelves, mobile shelves, steel structure platforms, etc. Since its operation, the company has won the trust of the vast number of users by optimizing raw materials, strong technical force, integrated professional production equipment, professional management team, professional logistics distribution and perfect after-sales service. It has undertaken the design, manufacturing and installation of warehouse shelf projects and is widely used in various industries such as factories, organs, medical, cultural and educational institutions, shopping malls and supermarkets.

Our company has always adhered to the principle of “balance of size”, “quality and cost” throughout the “soul” of the whole shelf standard, and is committed to designing high-quality products and perfect services to make customers truly satisfied. Years of experience in shelf design, production and operation has not only driven the development of the local economy, but also brought new management concepts and technologies to the local area, which has been continuously recognized by the users of major enterprises. The fluency shelves produced under its hegerls brand series are different from other shelf manufacturers.

Hegerls fluent shelf advantages

The advantage of fluent shelves produced by hegerls storage shelf manufacturer is that the goods stored in the warehouse can be deployed at any time, and the operation is simple. Roller type aluminum alloy and other flow bars are used to realize the interchangeability between the distribution center and the distribution center. Electronic labels can be used on both sides of the assembly line. Fluent shelves can realize material flow management. Compared with ordinary laminated shelves, it not only provides a storage space, but also saves space and improves the work efficiency of the enterprise. It is a better choice for Kanban management beside the production line of the factory and the picking operation of the logistics center. It can be used in conjunction with the electronic label system, and improves the cleanliness and safety of goods, At the same time, it can also reduce the repeated processing of goods. Fluent shelf is a kind of shelf widely used in daily life. Its appearance is not only conducive to the transportation of the factory industry, but also convenient for the daily life of users. Therefore, it is loved by everyone. This is reflected in the following four points:

◇ roller type design to achieve first in first out of goods

Roller type aluminum alloy and other fluent strips are used to realize the first in first out of goods by using the weight of goods. Goods are put in from the back of the shelf and taken out from the front. And can realize one replenishment and multiple pickup.

◇ fully assembled structure, can adjust the spacing between upper and lower layers

All adopt fully assembled structure, easy and convenient for disassembly, transportation, adjustment and movement. The floor height can be adjusted by an integral multiple of 50mm according to the needs of the goods, and the storage is convenient and flexible.

◇ the utilization rate of mass storage space is increased by more than 50%

It is suitable for the storage of large quantities of similar goods. It can be used with standard plastic turnover boxes or cartons, and the space utilization rate can be increased by more than 50%; It is suitable for use in auto parts factories.

◇ easy management of goods

It can be combined with the electronic label and bar code system to realize the informatization, standardization and standardized management of asset management, and comprehensively improve the efficiency and management level of enterprise asset management.

Composition of main components of haigris fluent shelf

The main components of fluency shelves include shelves, raceways, joint accessories series, etc. Any station assembly, widely used, such as automobile station, electronic industry and so on.

Wire rod: wire rod (also known as plastic coated pipe) is a welded steel pipe with plastic resin coating. In order to prevent the coating from separating from the steel pipe, they are bonded with special adhesive. The inner wall of the steel pipe is coated with anti-corrosion coating. The diameter of the standard wire rod material is 28mm and the wall thickness of the steel pipe is 1.0mm.

Fluency bar

Fluency bar is a supporting special shelf composed of profile steel and roller slide. It is mainly used for storage and shelf supporting products. It can be used as slide, guardrail and guide device to convey flexible movement. It is widely used in the assembly production line of the factory and the sorting area of the logistics distribution center. In particular, it can be combined with the digital sorting system to greatly improve the sorting and distribution efficiency of materials and reduce errors.

Fluent rack structure details display

◇ screw fixation

The connection is tightly reinforced with screws, with strong load and impact resistance.

◇ stable diagonal bracing

It is made of materials with high hardness and toughness, which is closely connected and has strong bearing capacity.

◇ welding leg piece design

Widen the contact surface between the welding leg piece and the ground, increase the friction, and make it more stable and reliable.

◇ column square hole

The double row square is easy to assemble and disassemble, and the floor height can be freely adjusted according to the demand.

So how to choose the right fluency shelf?

We learned from the hegerls storage rack manufacturer and our own production and sales experience that it is indeed a knowledge to buy shelves. There are many methods and skills. In this regard, hegerls storage rack shares with you the skills of buying fluent shelves.

◇ according to the category of materials loaded on the shelf and the container of materials loaded

The size of fluency rack needs to be related to the materials or containers it carries. The size can be customized. It is suggested that the manufacturer of haigris storage rack give the recommended size. On the one hand, it is relatively professional; on the other hand, if there is a problem, it can also share some of the responsibility.

◇ consider rack loading and unloading equipment

Whether there is a stacking equipment for shelves now. If there is, the wire rod fluent rack needs to consider the slewing radius, width and other factors of the equipment.

◇ ground bearing level of the warehouse itself

If the ground bearing capacity of your warehouse is only 1 ton and the shelf bearing capacity is 5 tons, the ground will inevitably sink or deform, and even collapse, causing safety accidents. Therefore, we should not only consider the space saving of fluent shelves, but also the load-bearing problem.

◇ factory shelf layout

Be sure to pay attention to the fluidity of materials after the construction of fluent shelves. Because of the different layout, the dimensions, load-bearing, loading and unloading equipment and other aspects of the shelves may be different.

Fluency shelves can be used independently or in combination with multiple units. It is widely used in warehouses, factory assembly workshops and various distribution centers. This shelf is simple, compact, beautiful, no energy consumption and no noise. Compared with other shelves, the operating efficiency can be increased by 50%. In the warehouse equipment, the shelf refers to the storage equipment specially used for storing the finished articles. Shelves play a very important role in logistics and warehouse. With the rapid development of modern industry, the logistics volume has increased greatly. In order to realize the modern management of the warehouse and improve the functions of the warehouse, it is required not only to have a large number of shelves, but also to have multiple functions, and to realize the requirements of flexibility and automation.

Post time: Aug-11-2022