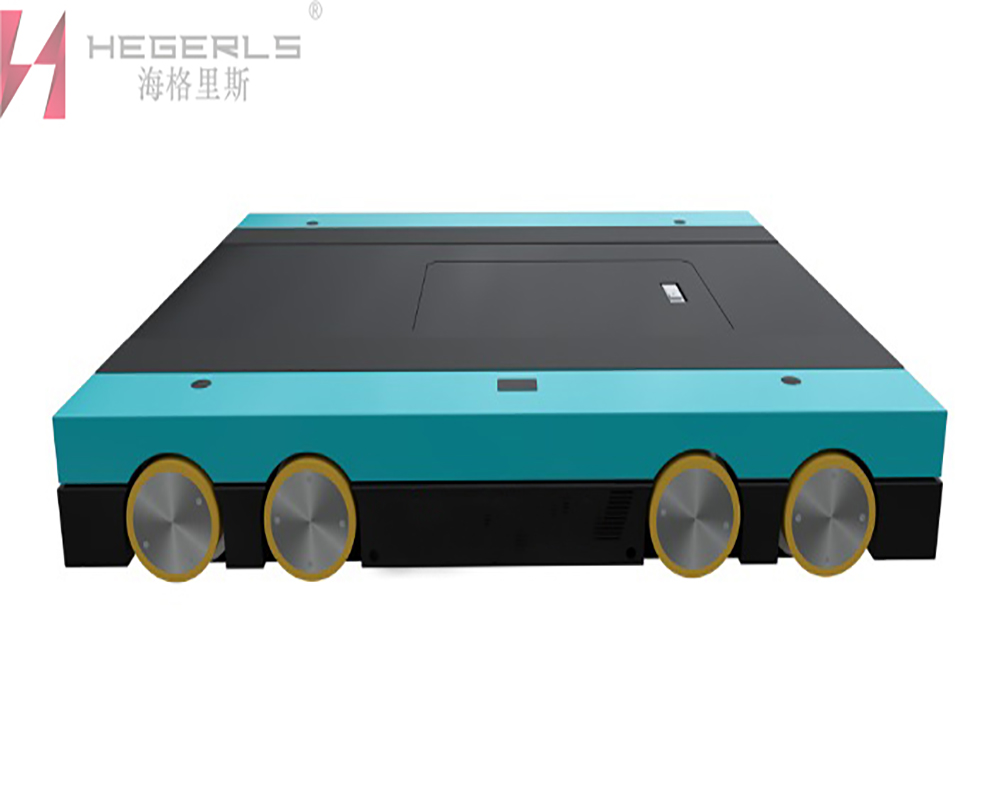

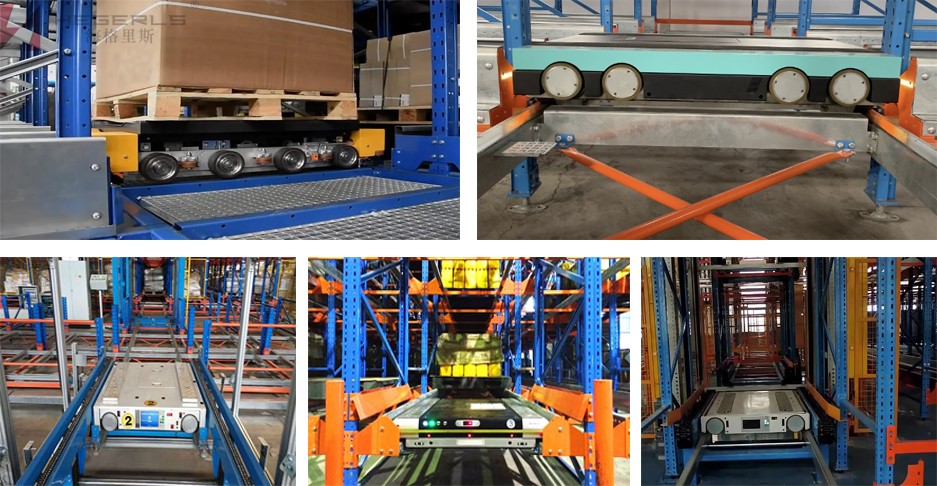

The HEGERLS pallet four-way shuttle car stereoscopic warehouse is an intelligent transportation device that integrates multiple functions such as four-way driving, track change in place, automatic transportation, intelligent monitoring, and traffic dynamic management. Also known as AGV, it can be programmed to perform operations such as picking up, transporting, and placing goods on the stereoscopic warehouse, and can communicate with the warehouse control system (WCS), in combination with the warehouse management system (WMS), RFID Logistics information technology such as barcode recognition enables automated identification of goods, single access, continuous access, automatic tally, and other functions. It is connected to wireless remote control and combines identification technologies such as RFID and QR code to easily realize automatic identification and access of goods on shelves.

According to the task requirements, the pallet four-way shuttle truck cooperates with the reciprocating elevator to complete the operation tasks in different layers of the shelf and different cargo lanes through the traveling rails. Under the control and scheduling of the warehouse monitoring system, the entire dense warehouse can achieve simultaneous operation of multiple layers and vehicles. The four-way shuttle car has the operation functions of bulk storage and withdrawal, cargo transfer movement, pallet counting, etc., to achieve rapid material delivery and inventory management. Its interior is equipped with obstacle avoidance function and fault alarm prompt function, which can provide safety protection and timely feedback of fault information.

The working principle of the Hercules HEGERLS pallet four-way shuttle vehicle inventory is to place the Hercules HEGERLS pallet four-way shuttle vehicle on the rack track under the pallet, under the guidance of the WCS system, with the lifting platform of the shuttle vehicle facing upward, lift the pallet unit to run to the destination, and then store the goods on the pallet to the cargo location.

The HEGERLS pallet four-way shuttle can solve the following pain points for enterprises:

Pain point 1: Improve storage flexibility

The modular design and implementation of the HEGERLS tray four-way shuttle car stereoscopic warehouse system endows its supermarket with flexibility. Among them, hardware such as intelligent four-way shuttle cars and high-speed hoists have multiple options, which are not only suitable for a variety of complex spatial layouts, but also have high spatial flexibility that can adapt to various industrial scenarios, which also improves the flexibility of the scene. In addition, the intelligent system performs implementation analysis of the operation situation and evenly distributes job tasks to ensure intelligent scheduling of multiple devices and tasks.

Pain Point 2: Expanding Storage Capacity

The four-way shuttle car stereoscopic storage system is mainly aimed at the operation scenario of dense storage of pallet stereoscopic storage, which can improve the storage capacity and space utilization rate in the warehouse, and its volumetric ratio can also be as high as 40% to 60%, which is also 4-6 times the volumetric ratio of the flat storage and 1.3-2 times the volumetric ratio of the stacker stereoscopic storage. Moreover, the access of the high-speed elevator equipped in the three-dimensional warehouse of the pallet four-way shuttle truck can fully utilize the height of the warehouse; The reduction of operation channels and the unmanned and mechanized operation of intelligent equipment can also effectively reduce the waste of equipment passage space.

Pain Point 3: Improving Storage Efficiency

The Hagrid HEGERLS tray four-way shuttle system can reasonably schedule standby equipment based on instructions, thereby reducing the startup time of the equipment and improving the overall inbound and outbound efficiency by more than 30% compared to the stacker. Compared to traditional manual operations, the pallet four-way shuttle vehicle three-dimensional warehouse system can also reduce the simple and repetitive manual round-trip work during the goods warehousing process through the efficient cooperation of multiple intelligent devices in the warehouse, thereby achieving unmanned management of warehousing business and improving the internal operation rate of the warehouse. At the same time, Hebei Walker will continue to optimize the path selection and planning algorithms of the software operating system for products under the HEGERLS brand of Haigris. This not only can promote a significant increase in the utilization rate of a single device, but also can achieve intelligent collaboration of software and hardware and collaborative work of multiple devices. Compared to traditional manual work, the overall efficiency of warehousing has been improved by 2-3 times.

Pain Point 4: Improving Product Quality

Most enterprises should be aware that in the current industry, most enterprises will adopt quality and performance testing of equipment components during project implementation and completion, but the drawback is that the types covered during on-site scheduling based on project requirements are limited. The Hagrid HEGERLS tray four-way shuttle vehicle three-dimensional library system will take the lead in completing multi-dimensional repeated testing of the module during design and factory inspection, to ensure that debugging and testing of various parameters of the module can be carried out in a variety of environments far higher than is feasible during the actual implementation process of the project, thereby providing higher quality delivery of software and hardware modules.

Pain Point 5: Reducing Investment Costs

The standardized and modular design of the Higgris HEGERLS tray four-way shuttle vehicle three-dimensional system can more accurately ensure that the construction of the intelligent shuttle vehicle three-dimensional warehouse can be invested in stages based on the actual storage throughput demand, with a large volume to meet the actual demand, effectively reducing the trial and error costs of enterprise warehouse intelligent transformation and the investment costs of the later stage of the project, and quickly achieving investment returns. In addition, the modular design of the hardware in the HEGERLS tray four-way shuttle vehicle three-dimensional warehouse system can also achieve unmanned operations in the warehouse. This work mode can also reduce the operating costs in the warehouse, reducing by more than 50% compared to manual operations.

Pain Point 6: Accelerating Delivery

After the high-dimensional integrated design and modular product implementation of HEGERLS, the deployment efficiency of the tray type four-way shuttle vehicle three-dimensional library system will be greatly improved. The warehousing project scheme design uses the Hebei Walker intelligent warehouse operating system to achieve intelligent design, with modular equipment plug and play, enabling intelligent collaboration of multiple devices and tasks without repeated debugging. The transformation and upgrading of warehousing projects can be efficiently deployed in 20 to 40 days, thereby achieving 100% high-quality delivery of warehousing projects without the occurrence of uncompleted projects.

Post time: Mar-23-2023