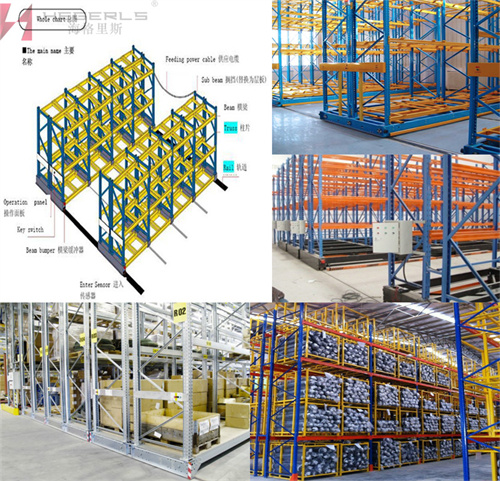

The electric mobile shelf system is one of the high-density storage shelf systems. It is a modern storage management system integrating the upper computer WMS warehouse management software, imported PLC, frequency converter, sensor, 7-inch touch screen, Android intelligent mobile terminal collector, RFID, bar code technology system and intelligent storage functions. It has high storage capacity, has active and passive protection measures, and has certain anti earthquake performance! The safety is very high, and the opening of the channel is also faster. The system only needs one channel, and the space utilization rate is very high. The motor drives the carrying trolley, and the trolley is placed with beam type shelves and cantilever shelves. The frequency conversion speed regulation makes the shelves extremely stable from start to braking, and the safety is guaranteed. The trolley is driven by the motor, and the pallet rack, cantilever rack, etc. are placed on the trolley. The variable frequency speed regulation enables the rack to realize automation, intelligence, safety and reliability from start to braking. According to the track form, the rack can be divided into two types: track type and trackless type. This kind of rack has frequency conversion control function, which can control the speed when driving and stopping to prevent the goods on the rack from shaking, tilting or dumping. A photoelectric sensor for positioning and a brakable gear motor are also installed at the appropriate position, which improves the positioning performance. The application of electric mobile shelves requires full understanding of warehouse space, stored goods, access methods and other factors to design reasonable logistics equipment application solutions.

The electric mobile shelf is laid by slide rails, the ground slide rails are stable and smooth, and the installation methods are various. Most of them adopt the magnetic guidance technology of unmanned carriers, and have emergency braking devices. The safety is very high. It has few channels, large unit storage area and high space utilization rate, which is three times that of ordinary shelves. It can be used with pallets to store heavy goods, but the cost is relatively high.

Structure principle and safety protection measures of electric mobile shelf

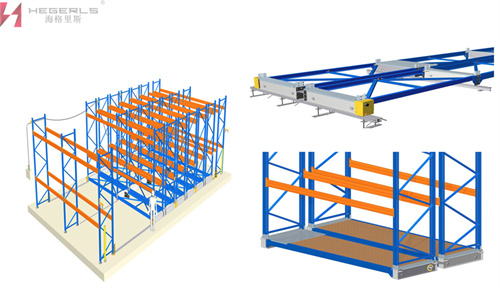

Structural principle: two rows of back-to-back shelves are installed on a basement plate in a group, which can be arranged in multiple groups. Each chassis is provided with multiple rollers, and each chassis is provided with several drive motors. By pressing the control button, the drive motor drives the entire bottom plate and the goods on the shelf through the chain drive, and moves along two or more tracks laid on the ground (or the original magnetic stripe is different – the sky track), So that the forklift can enter the moved site for goods access.

Safety protection measures: motor reducer and alarm sensing device are also installed on the chassis, which can not only improve the positioning accuracy of the rack movement, but also control the speed of driving and stopping, improve the safety of the rack travel, and prevent the goods on the rack from shaking, tilting or dumping; Each moving unit is equipped with motor frequency conversion speed regulation, guide rail detection on both sides, multi-level shelf interval control detection and other devices to detect foreign matters on the track and control the distance of moving shelves;

Motor overcurrent and overload protection to realize the protection of the drive motor; The system is equipped with unit mobile shelf start warning function, operation flashing light prompt, start and operation buzzer warning function to realize the safety protection of operators and equipment.

Working principle of electric mobile shelf

The heavy-duty mobile rack evolved from the heavy-duty pallet rack. It has a bare structure. Each two rows of racks are placed on the base. The base is equipped with traveling wheels and runs along the track. The chassis is equipped with motors, reducers, alarm and sensing devices. The system only needs to set 1-2 channels, and the space utilization rate is extremely high. The structure is similar to that of light and medium-sized mobile racks, which is different from that of heavy-duty mobile racks. The goods are transported by forklift trucks. The passage is usually about 3M. It is mainly used in places where the warehouse space is not large and the space is required to be used to the maximum extent. It is suitable for machinery manufacturing and other industries.

Characteristics of electric mobile shelf system

1) It is suitable for warehouses with high cost per unit area, such as cold storage, explosion-proof warehouse, etc.

2) No chain drive, more energy saving, more reliable structure.

3) Higher storage efficiency, less channels, no need to find channels for accessing goods.

4) Compared with ordinary shelves, the utilization rate of the ground can be increased by about 80%.

5) The picking ability of the electric mobile shelf can be about 100%.

6) It is simple in structure, safe and reliable, and can be moved in case of power failure. Compared with the ordinary fixed shelf, only the mobile trolley at the bottom is added, and the structure of the trolley is very simple. There are no complicated parts and components, and the operation and maintenance are simple and convenient. The track mode has a large bearing capacity, and the maximum weight of each room can be 32t. The special track is used to be flush with the ground and maintain the flatness of the ground. The trackless construction is simpler and more convenient, and does not need to damage the existing ground.

7) It only needs to be equipped with a forward moving forklift or a counterweight forklift to be used, and the requirements for forklift operation are low.

8) Good seismic resistance and stability: the moving columns without operation can be placed together, which expands the placement surface and improves the overall seismic resistance and stability. The goods on the shelf are not easy to slide because they are close together.

How to select qualified suppliers of electric mobile shelves?

1) Whether the supplier has its own design, development and team of automation products;

2) Use of shelf materials. Because the design standard of the electric mobile shelf is different from the load and deflection requirements of the traditional shelf, the customer needs to know the design principle and the specific difference between the two from the supplier.

3) The electric mobile shelf is a high-density storage mode, which requires the ground load. If the ground is unqualified, it needs to be redone. The floor can be made after detailed consultation with the supplier before purchase.

Hegerls storage rack manufacturer

Haigris storage shelf manufacturer is a professional shelf manufacturer in China, with more than 20 years of production, R & D and manufacturing experience. It is a light-weight shelf, a medium-weight shelf, a heavy-weight shelf, a cantilever shelf, a through shelf, a roller shelf, a press in shelf, a mobile shelf, a drawer shelf, an auto parts warehouse shelf (for 4S stores) It is a large-scale enterprise specializing in the production and processing of automatic three-dimensional warehouse shelves and peripheral equipment (storage racks, stacking racks, steel pallets, plastic pallets, storage cages, material boxes, handcarts, silent trolleys, climbing cars, logistics trolleys, loading trolleys, hydraulic lifting platforms, hydraulic boarding bridges, manual hydraulic pallet carriers, self-propelled electro-hydraulic loading and unloading forklifts, transport rollers, etc.), The raw materials used for the shelves are standard high-quality carbon steel, which is durable, solid and rust free, and ensures the product quality from the source. At the same time, Tigris shelves are welded with oxygen shielded welding, which has good crack resistance, small welding deformation and beautiful shape. Each column and beam of the shelf are designed and cut by our professional personnel with professional technology, so as to ensure the accurate size of the shelf. Professional spray pretreatment, oil removal, rust removal, phosphating, powder spraying, and then baking in a high-temperature oven. Each step is for the perfect shelf product. The factory has the production capacity of a professional shelf factory, and can customize various storage products according to your needs. Moreover, the electric movable shelves produced by hagris are more safe and reliable.

Why is it safe and reliable to say that haigris electric mobile shelf?

1) When selecting the control device, hagris uses professional industrial level key devices. The products fully meet the requirements of environmental temperature, humidity and protection. In the design of the operability of the software system, we fully consider the convenience of the customer and the ease of use, which increases the compatibility of the software system. In addition, we provide as many software and hardware interlocking protection measures as possible and detailed alarm information.

2) The electric mobile rack system has a multi-point emergency stop device.

3) The electric mobile shelf has a variety of protection measures, such as overvoltage, overcurrent, overload, overheating, overtime, etc.

4) The electric mobile shelf system has protection measures. The infrared photoelectric protection function is set in the horizontal and vertical directions of each two shelves. During the operation of the shelves, if there is an object intruded, the system will automatically stop and give an audible and visual alarm.

5) The electric mobile rack system has falling object protection. During the operation of the system, if objects are blocked between the two racks, the system will automatically stop and start the audible and visual alarm function.

Post time: Aug-16-2022