In the key links of warehousing and logistics, such as intelligent handling, picking, sorting, etc., box storage robots that meet multiple needs stand out. Because the box storage robot is picking and handling containers rather than shelves, the lanes between shelves can be set narrower, the storage density is higher, the space is saved, and then the warehouse rent is saved; Its "container to person" feature is more suitable for most of the built warehouses, with less difficulty in transformation and better flexibility and compatibility. The object of box storage robot operation is the unit material box smaller than the shelf, so it is more in line with the development trend of more diversified SKUs and more refined logistics operations. In recent years, it has been applied in e-commerce logistics and store distribution, manufacturing, cloud warehouse and many other scenarios. In 2020, box storage robots have become a hot spot in the development of major storage and logistics equipment manufacturers, and a heat wave of innovation and imitation is surging.

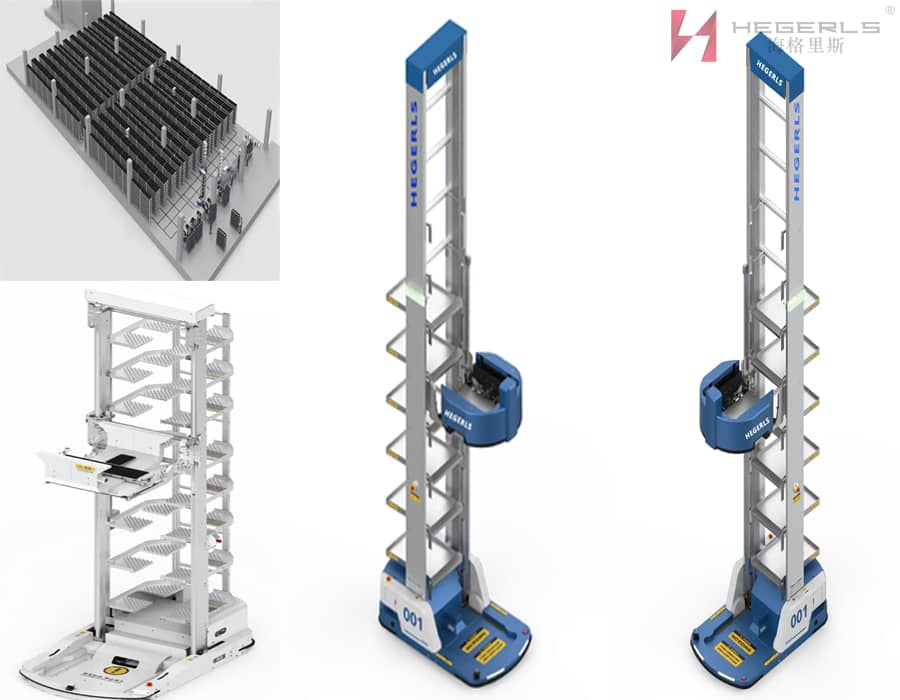

Hagris Kubo robot

The "container to human" robot kubao of hegerls has been developed and tested. The robot can accurately find the corresponding goods according to the order requirements. At the same time, through continuous iteration and product innovation, a number of kubao robots have been launched so far: multi-layer bin robot hegerls A42, double deep bin robot hegerls a42d, carton sorting robot hegerls a42n, telescopic lifting bin robot hegerls a42t and laser slam multi-layer bin robot hegerls A42 slam, gradually covering a variety of application scenarios of box storage robots. In this regard, today we will talk about the dynamic width adjusting box robot hegerls a42-fw.

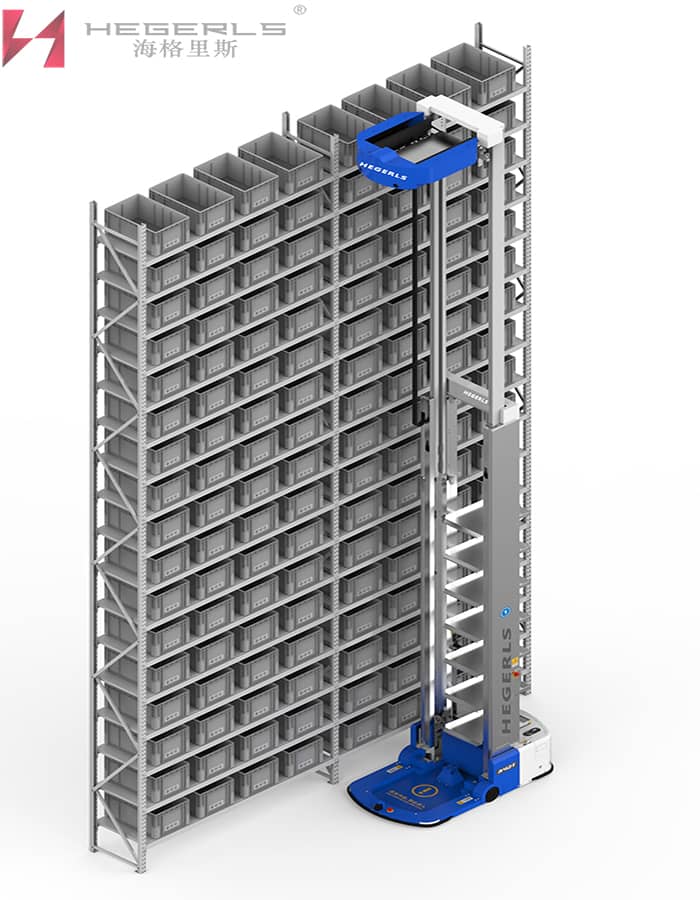

Hegerls a42-fw, a box type robot with dynamic width adjustment, adopts the dynamic width adjustment fork technology to dynamically adjust the fork width according to the size of the box, so as to provide picking and handling work for boxes of different sizes. With the haiq intelligent management platform based on powerful AI computing power, the robot can automatically allocate the optimal storage space according to the size of the box, ensure the minimum space between storage spaces, and maximize the utilization of shelf storage. According to the fact that hegerls a42-fw can increase the number of containers stored by nearly 20% compared with the fixed fork robot since it was put into use in major enterprises.

Characteristics of hegerls a42-fw dynamic width adjusting box robot

Kubao hegerls a42-fw dynamic width adjustment box robot independently develops the dynamic width adjustment fork technology, dynamically adjusts the fork size according to the box size, and realizes the picking and handling of cartons / bins of various sizes. As a new intelligent logistics handling equipment, hegerls a42-fw can realize intelligent walking in the storage space without the help of any track equipment, and has the functions of autonomous navigation, active obstacle avoidance and automatic charging. Compared with the traditional AGV "shelf to person" solution, kubao robot picking granularity is smaller. According to the order requirements issued by the system, it really realizes the transformation from the traditional "people looking for goods" to an efficient and simple "goods to person" intelligent picking mode. Compared with the solutions of stacker and automatic three-dimensional warehouse, kubao robot system can realize efficient deployment, with low overall deployment cost and stronger flexibility; At the same time, hegerls a42-fw supports the docking of a variety of logistics equipment, including shelves, conveyor lines, mechanical arms, multi-function workstations, etc. Flexible product design brings more operating space for customized solutions, comprehensively improves the efficiency of warehousing operations, optimizes the density of warehousing, and realizes the automation and intelligent transformation of the warehousing industry. Applicable scenario: it is suitable for the scenario of mixed storage of multiple sizes of containers, such as the application scenario of carton / material box mixed storage warehouse such as shoes and clothing, e-commerce, etc。

Advantages of dynamic width adjusting box robot hegerls a42-fw

Dynamically widened fork

Hegerls a42-fw, a dynamic width adjusting box robot, can adjust the forks to intelligently adapt to multi size bins and cartons;

Dynamic location

Hegerls a42-fw, a box robot with dynamic width adjustment, adopts haiq algorithm to dynamically adjust the width of forks, so as to intelligently match the optimal storage position;

Body width 900mm

The fuselage width of the dynamic width adjusting box robot hegerls a42-fw is generally 900mm, and the roadway width is narrow to 1000mm;

Shelf layer spacing

The spacing between the shelves of the dynamic width adjusting box robot hegerls a42-fw can be reduced to 250mm at least. The spacing here refers to that when there is a code, when there is no code, it can be reduced to 300mm;

Power consumption scenario

Hegerls a42-fw, a box type robot with dynamic width adjustment, generally adopts a 10s fast power exchange mode to meet the urgent power consumption scenarios of large and medium-sized promotion;

height

Here refers to the pickup height. The minimum pickup height range of the dynamic width adjusting box robot hegerls a42-fw is 190mm;

3D video technology

Hegerls a42-fw, a box type robot with dynamic width adjustment, adopts code free identification to pick up and place goods, and adopts advanced 3D visual recognition technology.

Hagerls - about the future

In fact, whether from the design and manufacturing of box storage robots by hegerls or from the use of box storage robots by major enterprises, box storage robot technology has immeasurable development prospects:

With the help of visual AI technology, the robot can accurately identify the position and height of the target material box, and realize the accurate picking and placing of the material box without code. In addition, it can also flexibly connect with a variety of storage and logistics equipment, including roller, shelf, latent AGV, artificial workstation and other operation platforms, which have a wider range of functions; In the aspect of path navigation, the box storage robot has developed from traditional two-dimensional code navigation to visual slam navigation and then to laser slam navigation. The technology is becoming more and more mature, which can effectively obtain external goods and environmental information, automatically avoid obstacles, and adapt to the more complex and changeable warehouse working environment; The original bin robot had only one bin position, and the picking efficiency was low. From the box storage robot developed by hegerls, hegris, a robot with multiple bin buffer positions has been developed, which can collect multiple target bins at a time, realize higher frequency picking and handling with fewer robots, and greatly improve the work efficiency and storage density.

Post time: Jul-04-2022