With the continuous upgrading of national consumption structure and the rapid development of fresh e-commerce, China's cold chain logistics and low temperature industry have entered a period of rapid development. Of course, how to meet the demand of large cold chain inventory and high delivery frequency has become one of the important issues to be considered in the development of cold chain. In this regard, Hebei haigris hegerls storage shelf manufacturer will explain several cold storage shelves in detail for those enterprises that need cold chain cold storage from the most basic storage point of view.

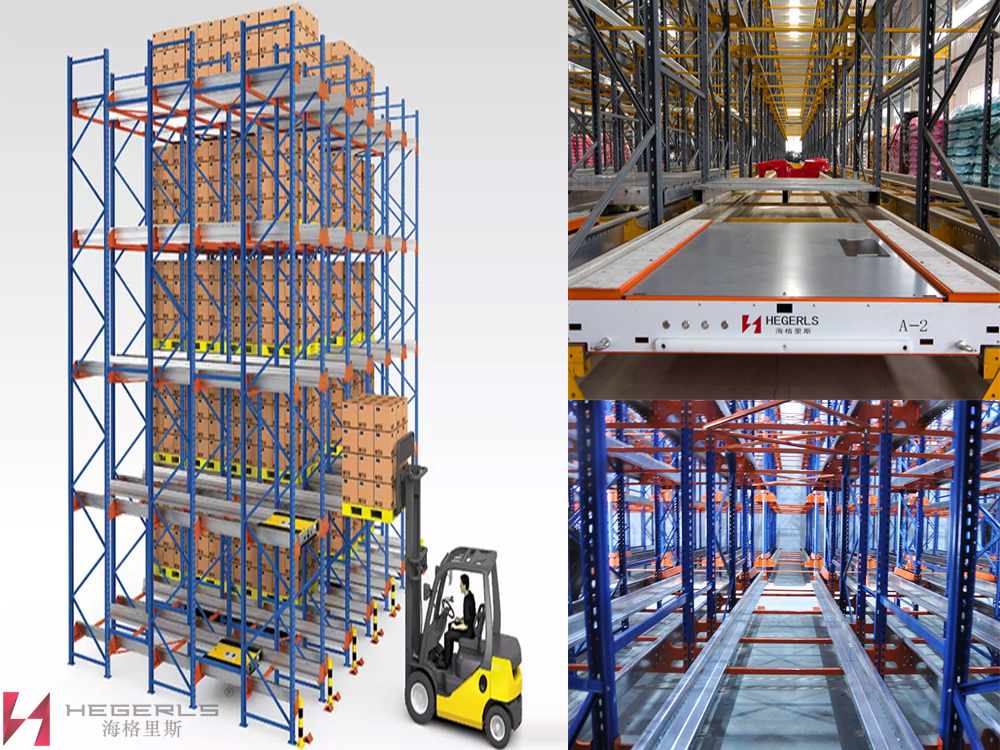

1、 Efficient intelligent shuttle rack

Shuttle rack is a storage rack type that is easy to realize automation and relatively economical. It is also a rack type that integrates single rack and related equipment. Generally, it is a complete high-density storage system composed of shelves, shuttle cars and forklifts of equipment and facilities. This high-efficiency access shuttle car is an intelligent robot, which can run on the fixed track of the shelf system according to instructions by reciprocating or looping. The shuttle car that can be remotely controlled is installed on the rack track, and then its automatic control system is used to realize the dense storage mode of goods. Its working principle is that the shelf is only put on the shelf at the entrance of goods at both ends, and then handed over to the shuttle trolley for operation. It reduces manual operation as much as possible, and the utilization rate of the warehouse can reach more than 85%. Compared with the cold chain cold storage, the shelf manufacturer of hegerls storage will focus on the particularity of the environment and the normal operation of the shelf and equipment system for the shuttle shelf suitable for the cold chain cold storage. It will be particularly rigorous in the preliminary design evaluation process. This is also because it is necessary to match the hegerls shuttle with the cold environment and have good control communication signals, Timely and effective personnel scheduling. The cold storage shuttle shelf solution provided by hegerls ensures that there are no basic problems in the whole cold chain cold storage link. At the same time, in the cold storage, the shelf of Hercules Hergels shuttle can reduce the time of low-temperature operation and improve work efficiency and safety.

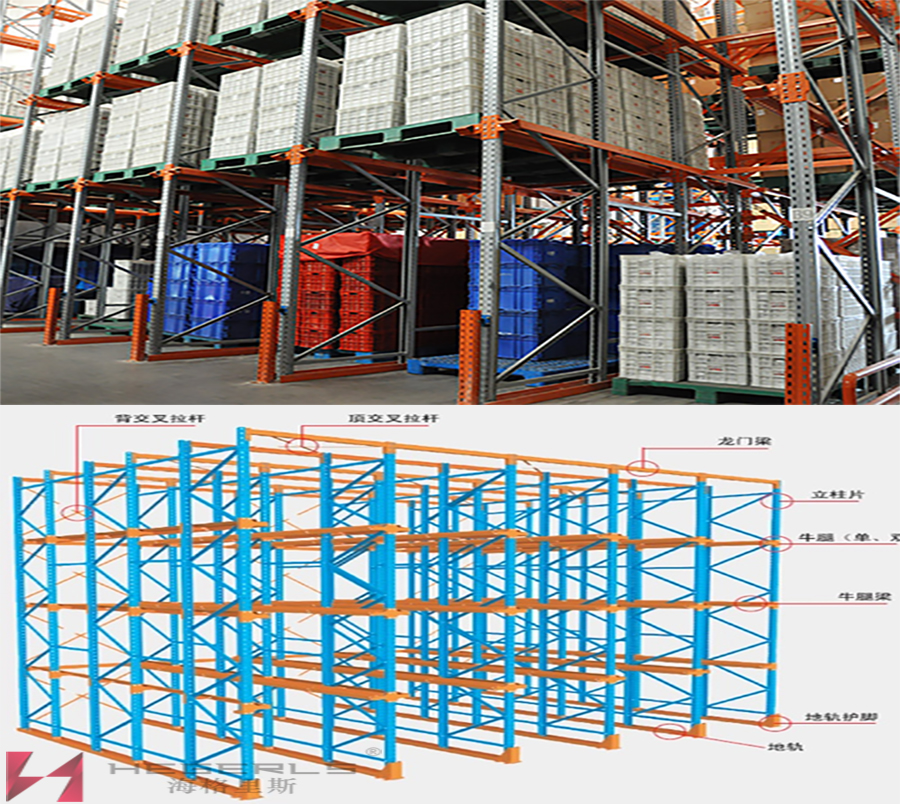

2、 Filo's drive in rack

Specifically, drive in rack is also one of the commonly used shelf types in conventional warehouse and cold storage. It connects several rows of column pieces. Unlike the cross beam shelf, it has no cross beam structure, is supported by its top beam, and is connected by guide rail and tray track. The pallet can be directly placed on the guide rail, equipped with facilities, and the forklift can drive into the channel to store goods, first in and last out (Filo), which is suitable for the storage of small varieties and large quantities. In this way, for the cold chain cold storage warehouse that needs frequent batch turnover, it is a more suitable shelf type to some extent. Its warehouse space utilization rate can be as high as 60% - 70%, which can fully meet the cold storage needs of the food industry. Compared with other shelves conducive to intensive storage, drive in rack is a storage equipment with low cost. For some cold chain storage enterprises with limited working capital, using drive in rack is a good choice of shelf type.

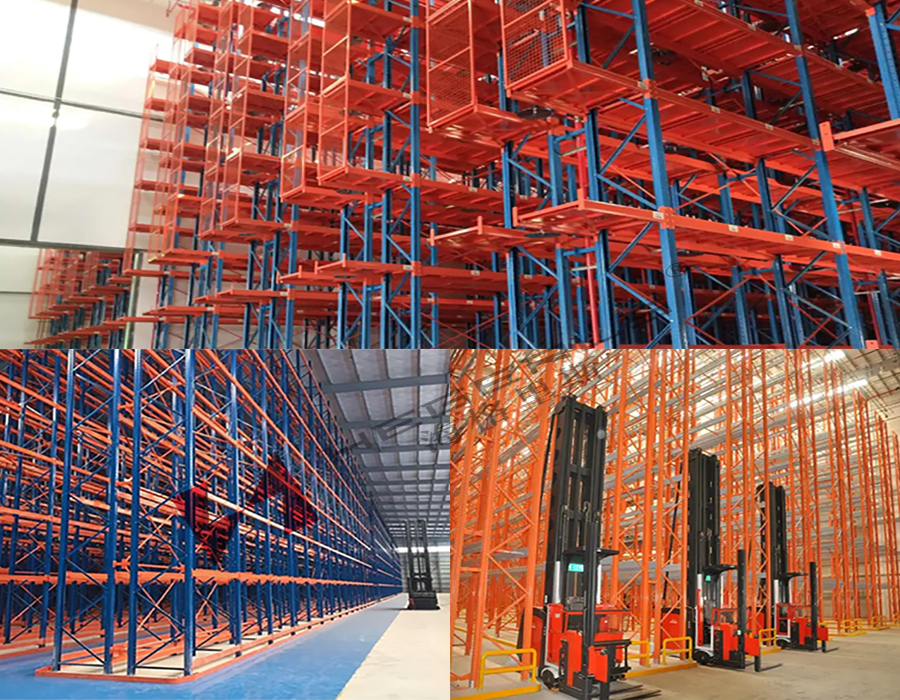

3、 Narrow roadway (VNA) shelf

In recent years, narrow roadway (VNA) shelves have gradually become one of the protagonists of cold chain refrigerated warehouses. Narrow roadway (VNA) shelf is a special storage structure derived from beam shelf, and its shelf structure is relatively similar to beam shelf. Narrow roadway (VNA) shelves only need to add guide rails on the ground, and its shelf height can be as high as 15m. Its warehouse space utilization rate can reach 50% and picking can reach 100%. Narrow roadway (VNA) shelf is an ideal choice for many enterprises to pursue first in first out and high capacity. In addition, narrow roadway (VNA) shelf needs to be equipped with three-way forklift equipment and facilities, which can run straight in the channel quickly. The forklift does not need to turn when accessing goods, but only needs the fork to rotate.

4、 Double position shelf (double deep storage shelf)

The double deep storage shelf is an extension of the cross beam shelf. It only needs to cooperate with the advanced two leg extension forklift for operation. It is specially designed for the general double row shelf to store the same kind of goods in depth, effectively reducing the occupation of channels and greatly increasing the storage capacity. Of course, Hercules Hergels storage shelf manufacturer will provide the specifications and load-bearing of this shelf type, and provide customized services according to user requirements.

5、 Gravity shelf

It can be said that the gravity shelf is a derivative of the pallet shelf, that is, the shelf type formed by upgrading on the basis of the heavy shelf. The roller type roller is installed on the cross beam of the shelf, and it is obliquely adjusted to an inclination of 3 ~ 5 degrees, so as to realize the displacement of goods by gravity. Gravity shelves also belong to the first in first out storage mode. Its biggest features are: low noise, environmental protection, no energy consumption, safety and reliability. It is precisely because there is no channel between shelf groups, which increases the utilization rate of space, which can be as high as 60%. Of course, this kind of gravity shelf is more suitable for logistics distribution center, cold chain storage, rotary allocation center, etc.

Hegris hegerls storage shelf manufacturer is a professional manufacturer of Hebei modern enterprise storage facilities and modern commercial retail store display equipment. After several years of industry baptism, it has become a model enterprise in the industry. It has such special storage production equipment, and has formed a complete production system from cold and hot coil longitudinal shear, general profile rolling, NC stamping, automatic welding to electrostatic powder spraying and other production lines. Our multi type storage shelves and storage equipment have been widely used in machinery, clothing, medicine, automobile, electronics, food, aviation, e-commerce, new materials, coatings, auto parts, textile, electric power, hardware, cold chain logistics, logistics and storage industries at home and abroad.

Recommendation of hegerls storage shelf manufacturer - shelf system purchase process

Hebei hegris hegerls storage shelf manufacturer, the purchase process of shelf system mainly includes: the user puts forward the requirements of warehouse shelf system - our company makes scheme design and selection - scheme discussion and Optimization - scheme rationality Evaluation of optimization degree - quotation - Determination of suppliers - contract signing - detailed technical decomposition design of shelf system - manufacturing of shelf system (material preparation, production, processing, surface treatment, packaging, transportation, etc.) - Installation of shelf system - acceptance.

The user's requirements for the warehouse shelf system shall generally include: warehouse plan, specification, characteristics and weight of unit (packaging) goods, specification, stacking height and load weight of unit pallet goods, access mode (manual access, mechanical access and automatic access) and access equipment, storage volume requirements, access frequency requirements, control mode, etc.

Post time: May-16-2022