In recent years, with the rapid development of the logistics industry, tray type four-way shuttle cars have been widely used in industries such as electricity, food, medicine, and cold chain, especially in cold chain logistics scenarios. Currently, the equipment has the ability to operate in environments ranging from -20 ℃ to -25 ℃, especially in cold chain systems below -18 ℃. The use of four-way shuttle cars for storage can greatly improve space utilization, And it can greatly improve the environment of the work area, making the work of workers more comfortable. Basic full scenario application coverage has been achieved, and key coverage has been achieved in some industries. It has the ability to handle X-axis and Y-axis materials, with high flexibility, especially suitable for irregular warehouse layouts, high density storage, and also suitable for operation modes with more product specifications and fewer batches.

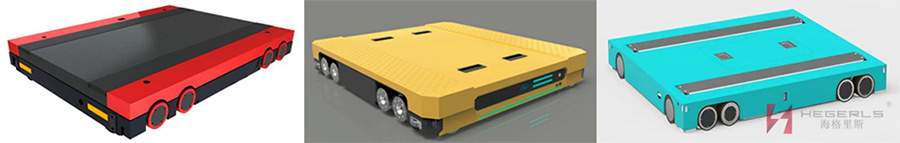

As a standardized product, the tray type four-way shuttle can be replaced with each other, and any four-way vehicle can continue to perform the task of the problematic four-way vehicle. The number of four-way vehicles is determined by a combination of factors such as the depth of the aisle on the shelves, the total cargo volume, and the frequency of inbound and outbound operations. With the continuous improvement of the ontology design, the four-way shuttle truck for pallets has gradually become an intelligent handling robot. Its operational efficiency and flexibility have greatly improved, and its application is no longer limited to storing goods on shelves. It can be used in scenarios such as warehouse handling and picking, which undoubtedly greatly increases the difficulty of system scheduling.

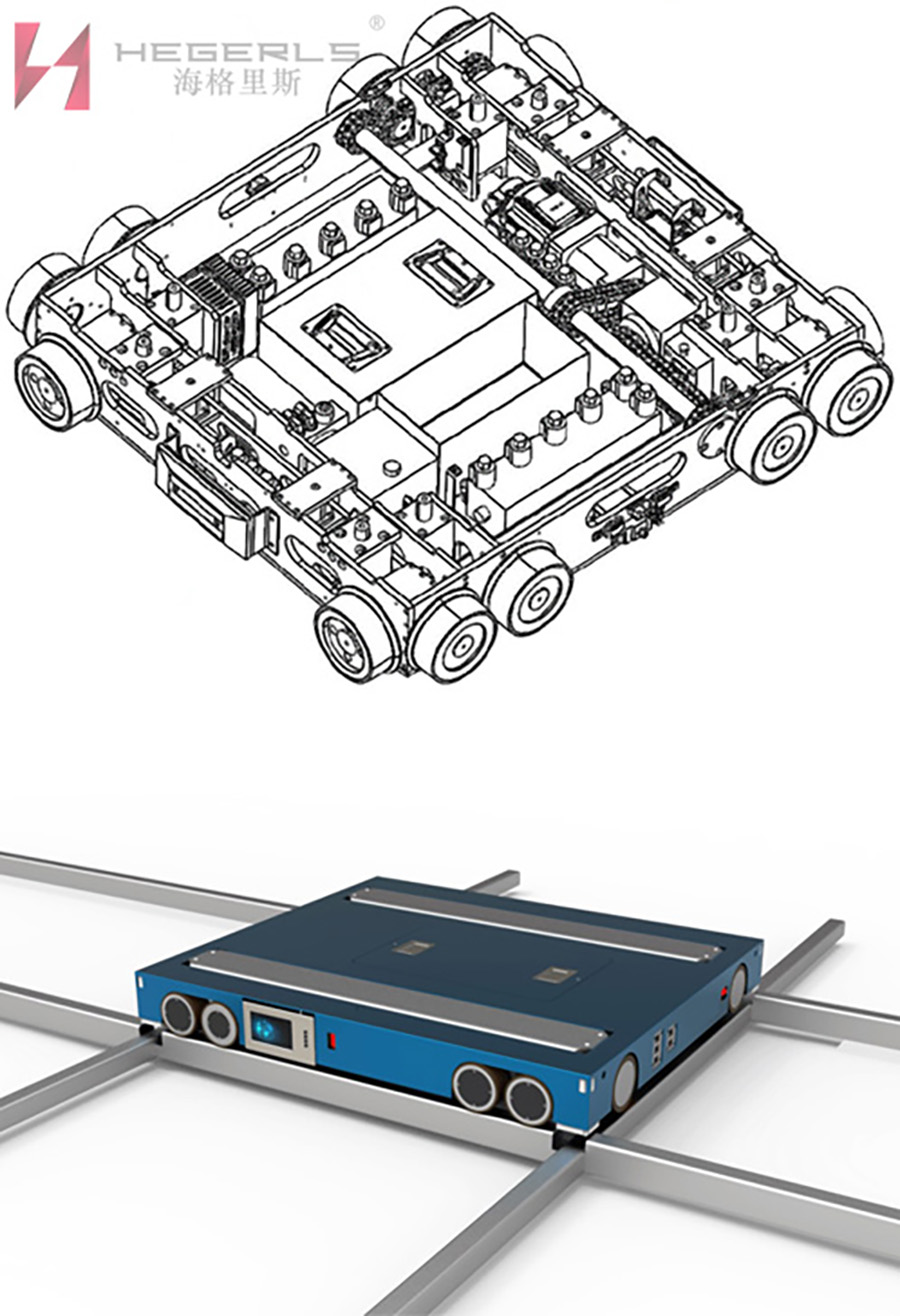

The cold storage series intelligent tray four-way shuttle car launched by HEGERLS adopts a lightweight design, optimizes the mechanical structure, and adds low-temperature protection design for electrical components in the overall vehicle design. The electronic control and core components are all made of first tier brand low-temperature cells, low-temperature imported PLCs, and power systems; To ensure the stability of the system, the four-way shuttle car and cold chain hoist undergo a 3 * 24-hour performance test in the factory's high and low temperature humidity laboratory before leaving the factory, and the core components undergo a 7 * 24-hour functional test. The Hagrid HEGERLS tray type four-way shuttle system also has a comprehensive level of cargo space management (WMS) and equipment scheduling capability (WCS). These software are not significantly different from traditional AS/RS, but the difference is the scheduling system for shuttle vehicles, which AS/RS does not have. They can ensure the stable and efficient operation of the overall system. To avoid waiting for the tray type four-way shuttle car and the elevator during operation, a cache conveyor line is designed between the elevator and the shelves. Both the tray type four-way shuttle car and the elevator hand over the trays to the cache conveyor line for transfer operations, thereby improving work efficiency.

The HEGERLS cold storage tray four-way shuttle can also work within the temperature range of 0~-25 ℃, seamlessly connecting the WCS warehouse control system and WMS warehouse management system. After receiving task instructions from WMS, AI algorithm optimization can be carried out according to the storage situation of goods, and the storage location and shuttle path can be reasonably planned to achieve optimization of storage location, path, and task allocation. And real-time viewing of transportation trajectories, inventory status, and other information of goods can better grasp the real-time status of goods in and out, achieve visual warehousing management, and help enterprises better grasp the storage status of goods.

As a new generation provider of smart logistics products and solutions, Hebei Woke Hegerls Robotics, based on AI native algorithm capabilities and a one-stop platform for robots, continues to create industry benchmark cases, providing efficient and intelligent warehousing and logistics solutions for customers in the food and beverage cold chain, including multiple enterprises. A typical case is as follows:

1) Intelligent dense cold storage of a certain Zhuhai enterprise

The core equipment is the Hegerls cold storage version four-way car and hoist.

Project highlights: The cold storage is 18m high, with a minimum temperature of -18 ℃ and over 7000 storage locations. Compared to stacker cranes, it saves 35% of electricity consumption and has a storage capacity that is more than 25% higher. It is flexible and meets the storage needs of third-party logistics and warehousing service providers for different goods.

2) A four-way vehicle storage facility of a certain Xinjiang sugar industry enterprise

Core equipment: Hegerls four-way vehicle+hoist+production palletizing robotic arm.

Project highlights: With a height of 22m and over 26000 storage locations, it can store 40000 tons of finished sugar. This intelligent intensive library is an important component of the enterprise's creation of a new generation of intelligent manufacturing demonstration production base.

3) A manufacturing factory of a certain Guangdong enterprise

Core equipment: HEGERLSAMR robot (intelligent handling system).

Project highlights: Each AMR can lift hundreds of kilograms of goods at once, without the need for supervision on site. It will charge itself and can operate normally even under black lights. Realized the automation and intelligent handling of materials, achieving timely and accurate material handling; Being able to automatically avoid obstacles greatly reduces the safety risks in the workshop; Further achieved digital management.

Hebei Woke Metal Products Co., Ltd. continues to pay attention to the demand for intelligent cold chain warehousing at home and abroad, focusing on the development and production of intelligent products, continuously strengthening its own technological research and development capabilities, and exploring more efficient ways to shape the value of cold chain. I believe that in the future development path, Hebei Woke will increasingly improve its technical support for domestic and international cold chain intelligent warehousing, empowering customers from the perspective of "smart logistics" and creating value.

Post time: Dec-14-2023