Project name: Self discharge Stereoscopic Storage (AS/RS) Phase III Project

Project partner: a new energy battery manufacturing company in Xi’an, Shaanxi

Project construction time: mid October 2022

Project construction area: Xi’an, Shaanxi Province, Northwest China

Customer demand: The enterprise is a new energy battery manufacturing company. The warehouse of the company is mainly used to store some materials needed for lithium battery manufacturing and some molded materials. The process of manufacturing lithium batteries is complicated and requires a lot of materials, which means that manual operation requires a lot of labor, and the efficiency of manual work can not meet the enterprise standards. In order to improve the internal situation of the warehouse and reduce the labor force in the warehouse as much as possible, so as to reduce the cost of the enterprise, the customer found our Hebei Walker Metal Products Co., Ltd. (self owned brand: HEGERLS) and hoped that our company could provide one-stop warehousing services such as design, development, production, manufacturing and construction of its warehouse according to their requirements. In the early stage, our company has undertaken the Phase I and Phase II automated stereoscopic warehouse project for this company, and put it into use in the later stage. Since the implementation of the project, it has been running well and managed in a standardized way, successfully meeting the customer’s storage needs, and has won praise from customers. Furthermore, in order to expand the storage demand, the company later connected with the management staff in charge of our company’s management of this project, successfully negotiated the third phase of the self discharge stereoscopic warehouse project, and started the construction of the self discharge stereoscopic warehouse project in October 2022.

Project implementation: The customer has already had the basic idea and direction when he found our company. After communication with our company, and in order to meet the customer’s expectations as far as possible, our company has arranged management staff and professional technicians who will connect with this project in the early stage to visit the other company again. After investigation, we found that the company has a large number of materials and warehouses. In order to reduce labor consumption, we finally worked out a clear design plan. The overall plan is: 2 self discharge stereoscopic libraries shall be established for the entire intelligent automatic stereoscopic library. At the same time, considering the size of the warehouse, our company plans to use multiple groups of high-rise shelves, 3 lanes, 3 7M high stackers, AGV automatic handling system and other supporting storage equipment and facilities required in a self discharge stereoscopic warehouse, so as to ensure that the space utilization rate of the warehouse can be maximized.

At the same time, the solution provided by our company integrates automated warehouse, automated production line, sorting robot, management software and automatic control system, automatic detection and charging and discharging equipment to achieve high-precision control under high temperature environment and meet the production process requirements of batteries from liquid injection to palletizing to finished product sorting; Each production unit uses two-dimensional code as information carrier to realize logistics automation and information synchronization between production processes such as battery high temperature aging, formation, sealing, normal temperature aging, charging, high temperature aging, cooling, capacity division, normal temperature storage, self discharge, detection, finished product sorting, etc., and automatically detect and track various performance indicators of the battery during production; An exception handling workstation is set in the middle of the formation, charging and capacity division production processes to replace the abnormal batteries in time. This intelligent production logistics system solution uses the characteristics of self discharge stereoscopic warehouse, such as high efficiency and compactness, and convenient battery access, to realize the automation and intellectualization of battery production process, reduce production energy consumption, and improve production efficiency.

Project summary: such efficient operation has high requirements for the equipment scheduling system and quality stability of the project. On the basis of ensuring the basic needs of customers, HEGERLS has also expanded the functions of the Phase III warehouse project.

Project implementation process: As a modern logistics facility, the self discharge stereoscopic warehouse can play an important role in improving the warehousing automation level of large and medium-sized enterprises. The automatic stereoscopic warehouse adopts the current domestic advanced warehousing technology, breaks through the planarization mode of the traditional warehouse, makes full use of the vertical space, occupies a small area and has a large storage capacity; The temperature, temperature, light, ventilation, etc. are all monitored by the computer and can be automatically adjusted to the best state; The warehousing and outbound of goods are all completed by computer controlled forklift and stacker, without manual handling and convenient access; It is equipped with an automatic identification system, which can accurately identify the warehousing time, qualified products, unqualified products and other information of the inventory goods, and automatically implement first in first out when shipping to ensure that the inventory goods will not be stored out of date; The goods are picked up accurately, which completely avoids the occurrence of falling and damaging goods that often occur in manual handling of goods; Among them, the computer system can realize the account processing in and out of the warehouse, and can connect with the customers’ computers to share information and resources.

HEGERLS self discharge stereo library

The self discharge stereoscopic warehouse built and installed by Hebei Walker Metal Products Co., Ltd. is an important part of the logistics system of a group enterprise in Xi’an. Under the high command of the computer management system, it can efficiently and reasonably store various types of materials and finished products. At the same time, it can accurately, timely and flexibly provide users with the required finished materials. It can also provide accurate information for the enterprise’s material procurement, production scheduling, planning, production and sales linkage, etc. The self discharge stereoscopic warehouse has the functions of saving land, reducing labor intensity, improving logistics efficiency, reducing storage and transportation losses, and reducing flow cost backlog. The self discharge stereoscopic warehouse project of a group in Xi’an undertaken by Hebei Walker Metal Products Co., Ltd. can maximize the practical implementation of the customer enterprise warehouse management system, as follows:

Original data establishment function:

At the initial stage, we can cooperate with different customers to develop different warehouse related commodity information, agent information, warehouse separation information, field staff information, etc.

Receipt/issue management function:

HEGERLS self discharge stereoscopic warehouse can formulate warehouse in/out information, storage allocation, order confirmation, warehouse in/out shift management method and warehouse in/out operation management. At the same time, carry out staff scheduling and work assignment for warehousing staff.

Inbound management function:

The HEGERLS self discharge stereoscopic library can be used to formulate warehouse entry information and information collection, warehouse entry information maintenance and update, offline warehouse entry, barcode management method, warehouse entry shift management method, warehouse entry operation management, warehouse entry list query, etc.

Permission management function:

HEGERLS self discharge stereoscopic library has played a certain role in the management method, authority control, role assignment, etc. of the entire system software, sales sub warehouse users.

Warehouse management function:

HEGERLS self discharge stereoscopic warehouse can carry out management methods for goods, operation areas, storage locations, etc., so as to achieve the management method of goods inflow, achieve the management of different warehouses’ inbound and outbound, and coordinate the scheduling between warehouses. It can also carry out logistics gap analysis, backlog analysis, warranty period early warning, inventory reports, and inbound and outbound reports for the inventory of each warehouse.

Customer order management function:

Record the problems fed back by the customer sheet, and give suggestions on optimization and modification in a timely manner.

The warehousing and outbound procedures of HEGERLS self discharge stereo warehouse are as follows:

Warehousing process of HEGERLS self discharge stereo warehouse:

Each warehousing area of the warehouse is equipped with a warehousing terminal, and each lane entrance is equipped with two finished product warehousing platforms. For finished materials to be warehoused, the operator of the warehousing terminal shall input the name, specification, model, quantity and other information of the finished materials, and then receive the warehousing data through the human-computer interface through the control system. According to the principles of uniform distribution, bottom-up, bottom-up, bottom-up, nearest warehousing, and ABC classification, the management calculator automatically allocates a storage location and prompts the warehousing lane. The operator can send the materials loaded on the standard pallet to the storage platform of the tunnel by the electric equipment according to the prompts. Then the monitoring command will stack the pallets and store them in the designated storage location.

There are two types of stock in processing of inventory data: first, the staff is required to enter the name (or code), model, specification, quantity, stock in date, production unit and other information of the finished material on the stock in pallet on the stock in client through the human-computer interface after the finished material stock in; The second is warehousing through pallets.

Warehouse out process of HEGERLS self discharge stereo warehouse:

The two ends of the bottom floor are the warehouse out areas for finished materials. The central control room and the terminal are respectively equipped with a warehouse out terminal. LED display screens are set at each lane entrance to prompt the exit number of this plate of goods to be delivered to the assembly platform. For finished materials to be delivered, after the staff has keyed in the name, specification, model and quantity of the finished materials, the control system will find out the pallets that meet the delivery conditions and have the same or slightly more quantity according to the principles of first in first out, nearest delivery, and delivery priority, and then verify the corresponding account data to automatically send the finished pallets of various materials to be delivered to the delivery platform at each lane entrance, Take it out and send it out with facilities. At the same time, the outbound system forms an outbound document on the client after completing the outbound operation.

Handling process of empty disk returned from HEGERLS self discharge stereo library:

After part of the empty pallets from the bottom floor are manually stacked, the staff will type in the empty pallet return operation instruction, and then the staff will use the equipped facilities to send the empty pallets to a certain lane crossing on the bottom floor according to the display. The stacker will automatically send the empty pallets back to the original entrance of the stereo warehouse, and then the workshops will drag the empty pallets away to form a certain turnover.

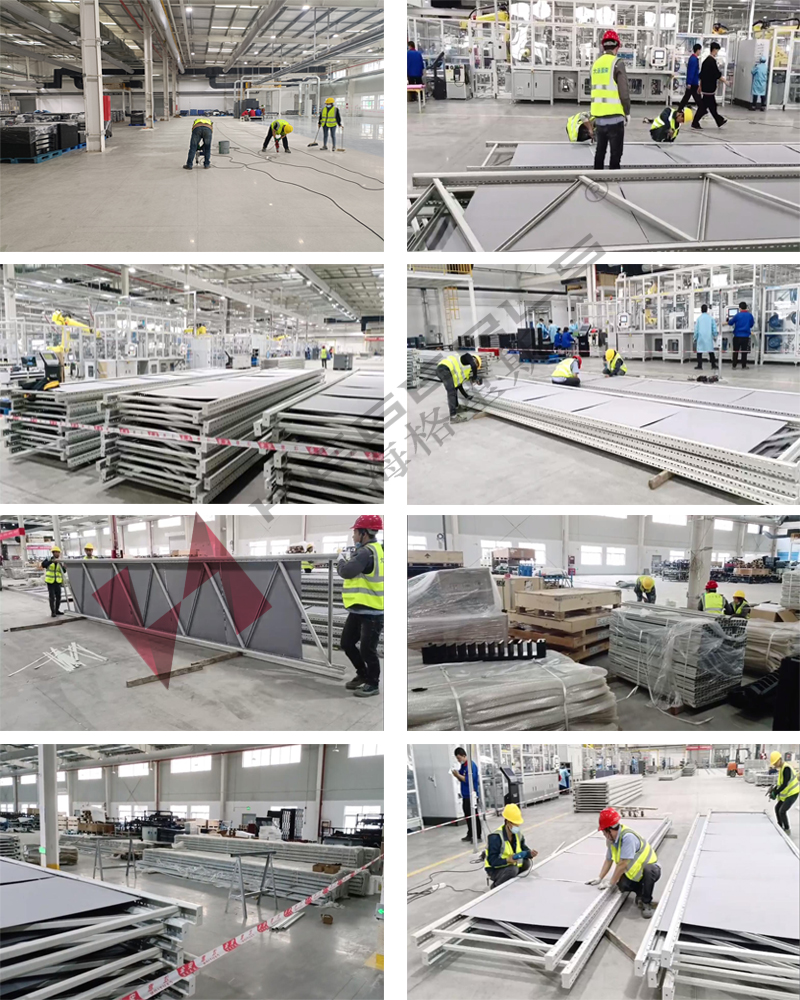

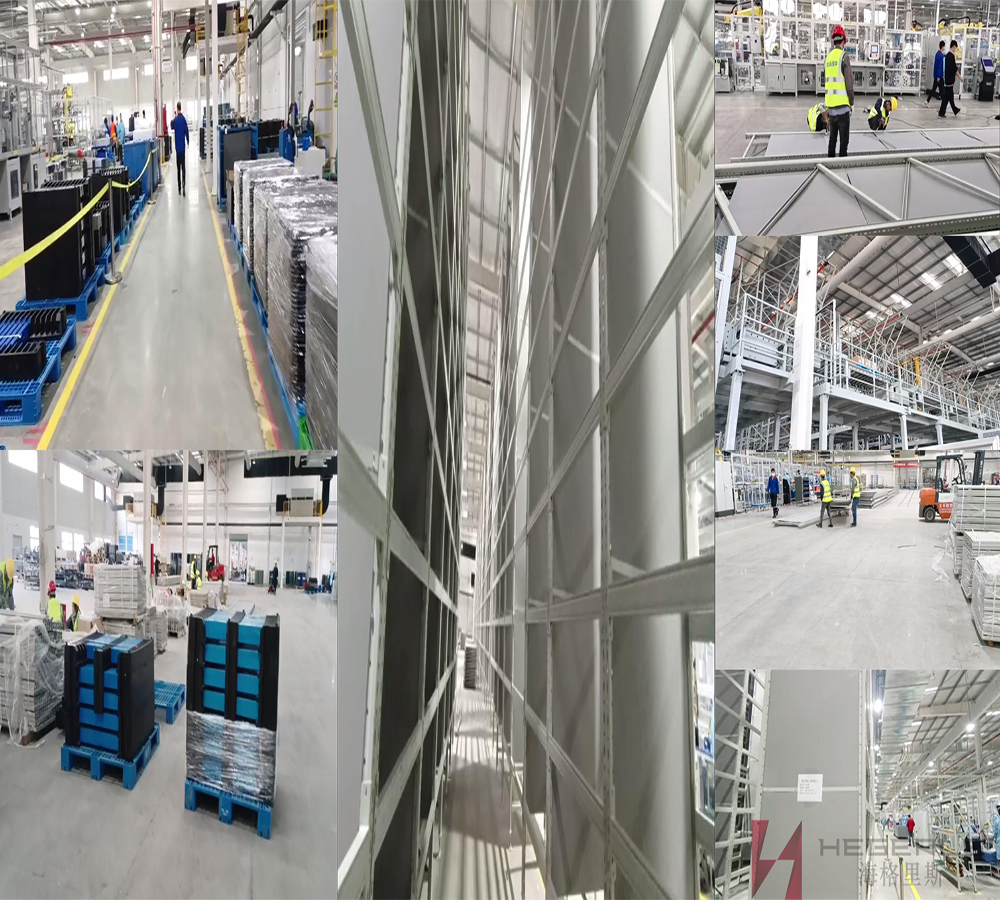

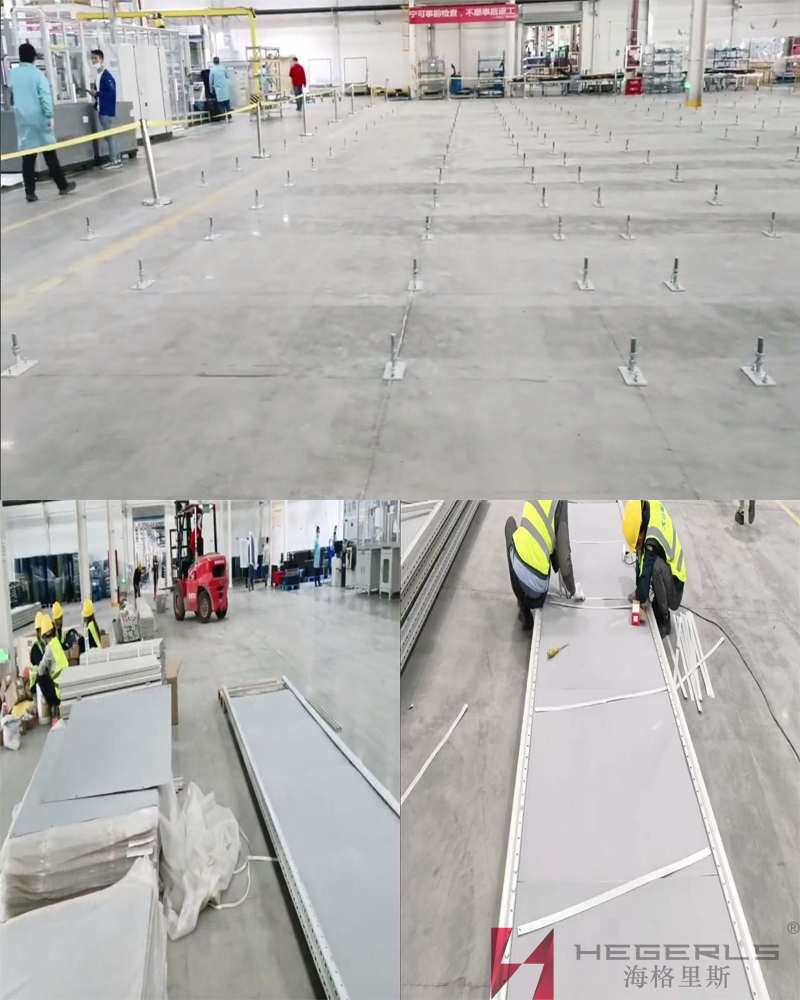

Project construction site:

Post time: Oct-31-2022