The bin type four way shuttle robot is a robot used for bin access. Compared to the limited application of the pallet type four-way shuttle truck, the bin type four-way shuttle truck is widely used, which can be applied to various warehouse types, and can flexibly increase or decrease the number of trolleys to match actual needs. On the one hand, it is related to its flexibility and flexibility. More importantly, the development of e-commerce has promoted the rapid development of disassembly and sorting. The high efficiency of the bin type AGV robotic four-way shuttle is also one of the important reasons for its popularity. Currently known applications include various large-scale storage systems (especially those with large storage capacity and low frequency of inbound and outbound storage), such as libraries and archives. In addition, there are prospects for application in other aspects of logistics, such as production line side warehouses, sorting systems, and so on.

The bin type AGV robot four-way shuttle car is mainly suitable for 600 × 400 standard boxes, with a carrying capacity of 50kg, future systems will mainly seek serialization in terms of size and fork type to meet market demand. Standardization and serialization are the only way forward for product development. However, as each shuttle vehicle undergoes rigorous testing before leaving the factory, and each new model undergoes rigorous finalization testing, these tasks will pose challenges to serialization. From experience, because it is necessary to build a test bed for each new product, the testing of new products is not only time-consuming and labor-intensive, but also affects production capacity. However, the main brand of Hebei Woke Metal Products Co., Ltd., HEGERLS, is different from other manufacturers.

Main brand: HEGERLS

HEGERLS is the main brand of Hebei Woke Metal Products Co., Ltd., with headquarters in Shijiazhuang and Xingtai production bases, and sales branches in Bangkok, Thailand, Kunshan, Jiangsu, and Shenyang. It has a production and research base of 60000 ㎡, 48 world advanced production lines, and more than 300 people engaged in research and development, production, sales, installation, and after-sales service, including nearly 60 senior technicians and engineers with professional titles. Over the years, the company has experienced a process of development and expansion. Currently, the company’s products are distributed throughout the country and have provided shelves for all industries. Especially in recent years, with the rapid development of the northwest logistics industry, the company has undertaken shelf projects for multiple large logistics distribution center warehouses, many of which are large-scale engineering projects with exemplary effects in the industry.

The products of HEGERLS include:

Storage rack: shuttle rack, crossbeam rack, four-way shuttle truck rack, pallet four-way shuttle truck rack, medium rack, light rack, pallet rack, rotary rack, through-type rack, three-dimensional warehouse rack, attic rack, laminated rack, cantilever rack, mobile rack, fluent rack, drive-in rack, gravity rack, high-level storage rack, press-in rack, sorting rack Narrow aisle shelves, heavy tray shelves, shelf shelves, drawer shelves, bracket shelves, multi-layer attic shelves, stacked shelves, three-dimensional high shelves, universal angle steel shelves, corridor shelves, mold racks, dense cabinets, steel platforms, anti-corrosion shelves, and so on.

Storage equipment: steel structure platform, steel pallet, steel material box, smart rack, storage cage, isolation net, elevator, hydraulic pressure, shuttle car, two-way shuttle car, parent-child shuttle car, four-way shuttle car, stacker, mesh partition, climbing car, intelligent transportation and sorting equipment, pallet, electric forklift, container, turnover box, AGV, etc.

New intelligent robot series: namely Kubao robot series, this series of products include: carton picking robot HEGERLS A42N, lift picking robot HEGERLS A3, double deep bin robot HEGERLS A42D, telescoping and lifting bin robot HEGERLS A42T, laser SLAM multi-layer bin robot HEGERLS A42 SLAM, multi-layer bin robot HEGERLS A42, dynamic width adjusting bin robot HEGERLS A42-FW, intelligent management platform, workstation Intelligent charging pile.

Automated stereoscopic library: shuttle type stereoscopic library, beam type stereoscopic library, tray type stereoscopic library, heavy shelf type stereoscopic library, automated storage stereoscopic library, loft type stereoscopic library, laminate type stereoscopic library, four-way shuttle vehicle stereoscopic library, mobile type stereoscopic library, narrow lane type stereoscopic library, unit type stereoscopic library, through-type stereoscopic library, cargo type stereoscopic library, automated cabinet type stereoscopic library, strip shelf type stereoscopic library, picking type stereoscopic library, semi-automatic stereoscopic library Linear guide rail type stereoscopic library, U-shaped guide rail type stereoscopic library, traverse guide rail type stereoscopic library, low level stereoscopic library, middle level stereoscopic library, high level stereoscopic library, integral stereoscopic library, layered stereoscopic library, stacker type stereoscopic library, circular shelf stereoscopic library, and so on.

Warehouse management system: Order Management System (OMS), Warehouse Management System (WMS), Warehouse Control System (WCS), and Transportation Management System (TMS). The warehouse management system provided by HEGERLS can promote the efficiency improvement and cost reduction of the entire chain, achieving a true “intelligent warehouse and distribution integration”.

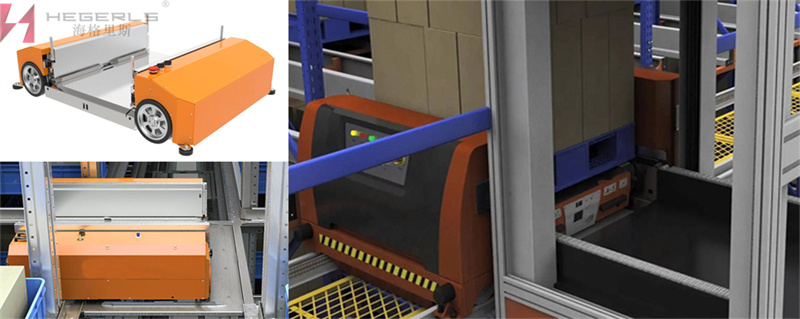

The biggest difference between the HEGERLS hopper type four-way shuttle cars is that their core equipment is designed to be modular and standardized, making it easy to cope with business expansion. Not only that, but also a deep learning heuristic search algorithm is used to construct a simplified path plan. High order S-curve planning control technology and 5G communication technology are used to ensure the efficiency and safety of operating equipment. High cost performance can reduce customer investment costs and optimize resource utilization. The HEGERLS hopper type four-way shuttle truck is suitable for various turnover boxes, cardboard boxes, and other goods with a flat bottom, a certain supporting force, and not easy to deform.

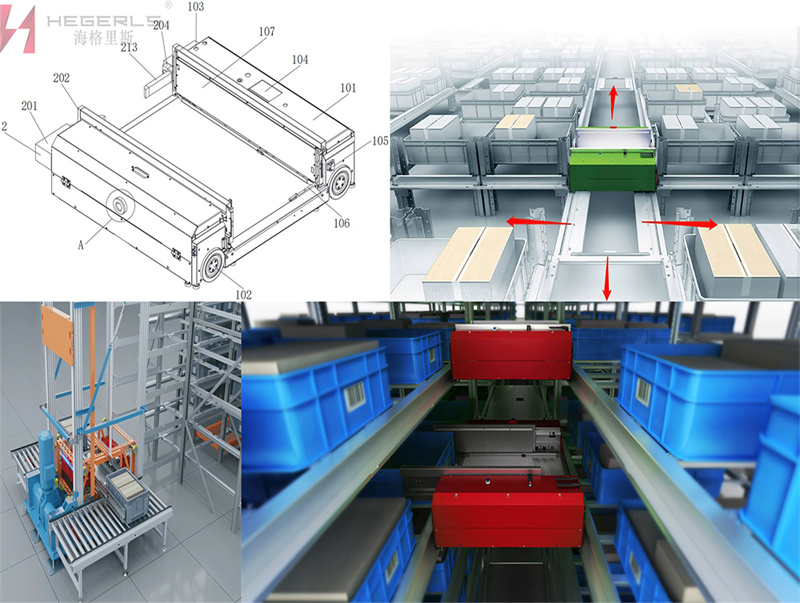

Like the pallet four-way vehicle, the bin type four-way shuttle is often used for collecting goods and queuing during the delivery process. The difference between it and the tray is that the material box can directly dock with the telescopic belt conveyor, thereby completing the loading work more directly. For situations where there are multiple shipping destinations, shuttle buses can also play the role of queuing to resolve previous issues regarding the loading sequence. Especially in the goods to people picking system, as the car can change layers through the elevator, in fact, it can operate flexibly in three-dimensional space. This is mainly because after the unit becomes smaller and lighter, there are many ways to transfer the load. The simplest way is to use a fork. To improve storage density, double depth forks can be used, and sometimes the width of the forks can be changed to accommodate different widths of cartons. The fork is the most important component of a shuttle car. At the same time, in order to improve working efficiency, the speed of the trolley will be as high as 5m/s. Due to the use of a clamping device, the acceleration of the trolley can reach 2m/s2, which greatly improves the working efficiency of the trolley. For a hoist, the lifting speed will generally reach above 4m/s to match the efficiency of the entire system.

There is no doubt that the market potential of the material box four-way shuttle technology is very large. The degree of market acceptance of a technology depends on the reliability and maturity of the technology itself, and successful cases of technology application are the primary conditions for market acceptance. At present, whether influenced by the “goods to people” delivery technology trend or catalyzed by intelligent manufacturing, the application scenario of the material box four-way shuttle vehicle will continue to expand, with a broad market prospect.

Post time: Mar-28-2023