For commercial distribution and industrial production enterprises, how to efficiently and low-cost carry out low sorting, transportation, palletizing, and warehousing to improve the utilization efficiency of warehouse space is an industry pain point that most enterprises urgently need to solve. In order to address the aforementioned pain points, in recent years, logistics and warehousing integrators, shelf manufacturers, AGV manufacturers, material box four-way shuttle vehicle manufacturers, and startups have continuously entered the field of pallet four-way shuttle vehicles.

With the rise of e-commerce at the end of the 20th century, the traditional “high shelf+pallet+forklift” picking model has gradually been marginalized due to its inability to adapt to personalized and customized market demands. At this point, the tray four-way shuttle vehicle that can “unbind” the warehouse’s alleyways from the elevator and achieve cross aisle operation in three-dimensional space also stands out.

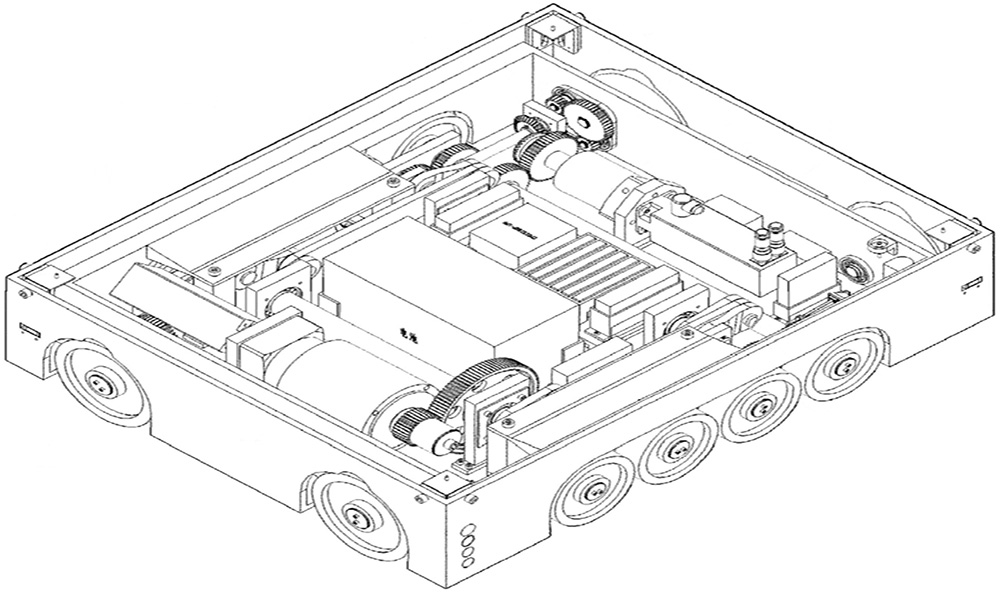

The so-called four-way shuttle car refers to a shuttle car that can complete “front, back, left, right” operation. Structurally speaking, it has two sets of wheel systems, responsible for the movement in the X-axis and Y-axis directions, achieving the ability to transport and traverse within the same tunnel, as well as cooperate with elevators to switch between different tunnels within the same layer. At the same time, it can also adapt to various pallets such as T-shaped pallets and Chuan shaped pallets. As a standardized product, the pallet four-way vehicle can be replaced with each other, and any four-way vehicle can continue to perform the task of the problematic four-way vehicle. The number of four-way vehicles is determined by a combination of factors such as the depth of the aisle on the shelves, the total cargo volume, and the frequency of inbound and outbound operations.

Hebei Woke Metal Products Co., Ltd. (referred to as “Hebei Woke”, independent brand: HEGERLS) starts from different technological paths and seeks the “lowest cost” and “most reliable” solutions based on different “business scenarios”. From shuttle products to logistics robot product lines that cover all scenarios of access, handling, and sorting, and then to one-stop services, Hebei Woke has undergone more than 20 years of development. In response to changes in market demand, it has actively upgraded and transformed its role, continuously bringing valuable services to domestic and foreign users. Over the years, it has not only carried the development and growth of Hebei Woke itself, but also made tremendous contributions to the innovation and progress of logistics equipment at home and abroad.

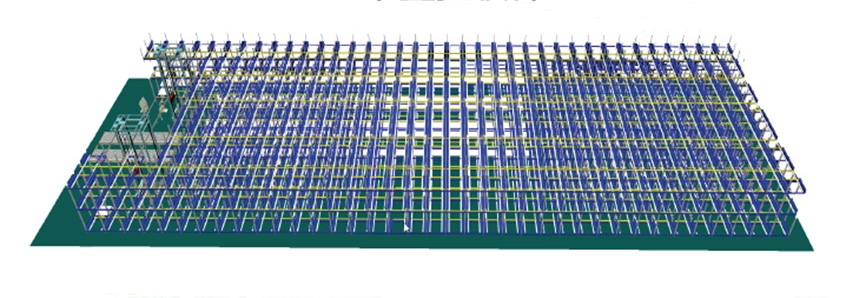

In order to meet the market’s demand for high-density intelligent warehousing, Hebei Woke has launched the HEGERLS pallet four-way shuttle with high flexibility and scalability. When paired with latent top up AGVs, intelligent warehousing equipment, and supporting intelligent control systems, it has made great efforts to solve the problems of low height, small space, small storage capacity, insufficient line side storage locations, and improper picking methods in traditional underground storage.

The HEGERLS pallet four-way vehicle solution is not a simple dense storage system, but a highly flexible and dynamic intelligent warehousing solution. Its core advantage lies in discrete devices and distributed control, which means that customers can flexibly configure the number of four-way vehicles according to their needs and schedule their efficient operation through software. User enterprises can flexibly combine and deploy as needed, just like building blocks. Unlike AS/RS stacker cranes that can only operate on fixed paths, the four-way vehicle system is standardized due to its hardware products, namely the four-way vehicle, which can be replaced with a new car at any time in case of failure. Secondly, flexibility is reflected in the “dynamic scalability” of the entire system. User enterprises can increase or decrease the number of four-way vehicles at any time according to changes such as off peak seasons and business growth, improving the system’s carrying capacity. With the continuous improvement of the ontology design, the four-way shuttle truck for pallets has gradually become an intelligent handling robot. Its operational efficiency and flexibility have greatly improved, and its application is no longer limited to storing goods on shelves. It can be used in scenarios such as warehouse handling and picking, which undoubtedly greatly increases the difficulty of system scheduling.

Hebei Woke has in-depth research on WMS, WCS, and RCS robot scheduling systems. Empowered by a powerful underlying AI engine and built on massive data, Hebei Woke has developed an intelligent brain called WMS, which provides customers with a complete set of cost reduction and efficiency improvement solutions. It can control ultra large warehouses with over one million levels of storage space, helping customers solve the cost problems of labor costs, land costs, and overall warehouse operation. In addition, the Hebei Woke RCS intelligent multi device cluster scheduling system can meet the cluster scheduling needs of large-scale AMR robots and other robots that customers need in both intelligent manufacturing and intelligent logistics systems. It adopts a microservices architecture and AI algorithms, which can directly control robots and other peripheral intelligent devices, and interface and cooperate with WMS, ERP, and WCS to fully leverage and optimize the efficiency of smart robot equipment, thereby improving the operational efficiency of the equipment.

Based on its powerful AI capabilities and WMS brain, Hebei Woke has analyzed traditional storage methods, picking methods, conveying and sorting modes, as well as mature equipment production capacity in the current market. It has designed and developed numerous intelligent, reliable, and high return on investment solutions for large-scale multi-layer shuttle garages that meet larger shipping needs with high flow and inventory. This solution not only has multiple modules such as multi task allocation optimization, real-time calculation and optimization of multiple paths, multi path conflict detection, and fault handling, but also solves the technical difficulties of multi task concurrency and multi path planning. The introduction of such solutions truly helps users solve practical problems and effectively improves overall efficiency.

Post time: Feb-04-2024