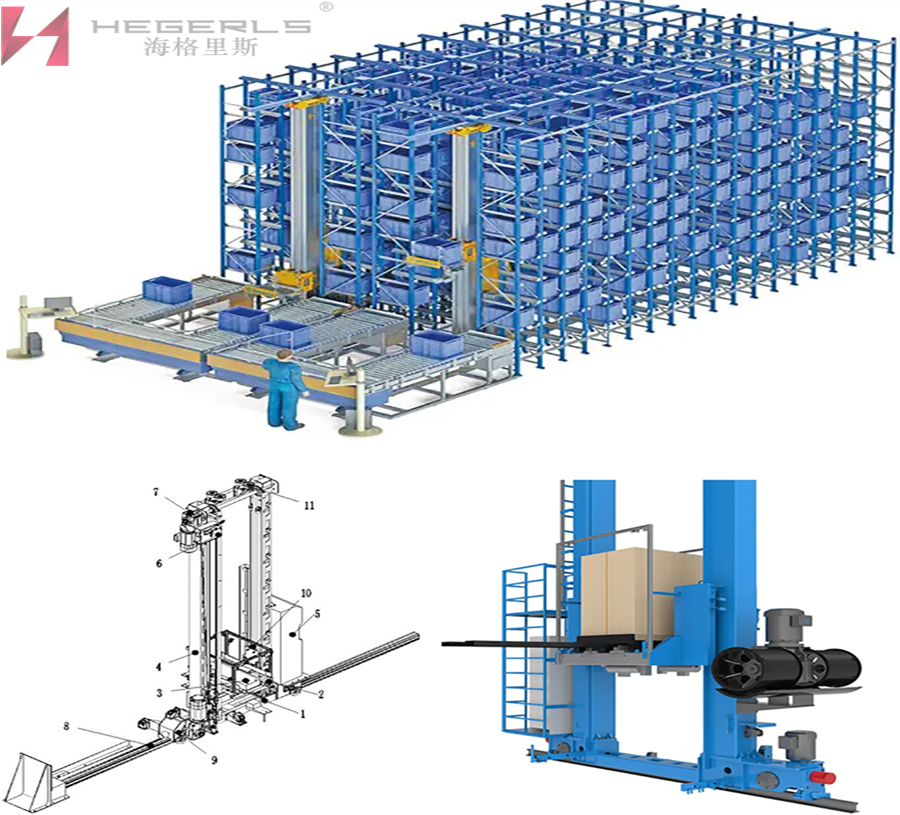

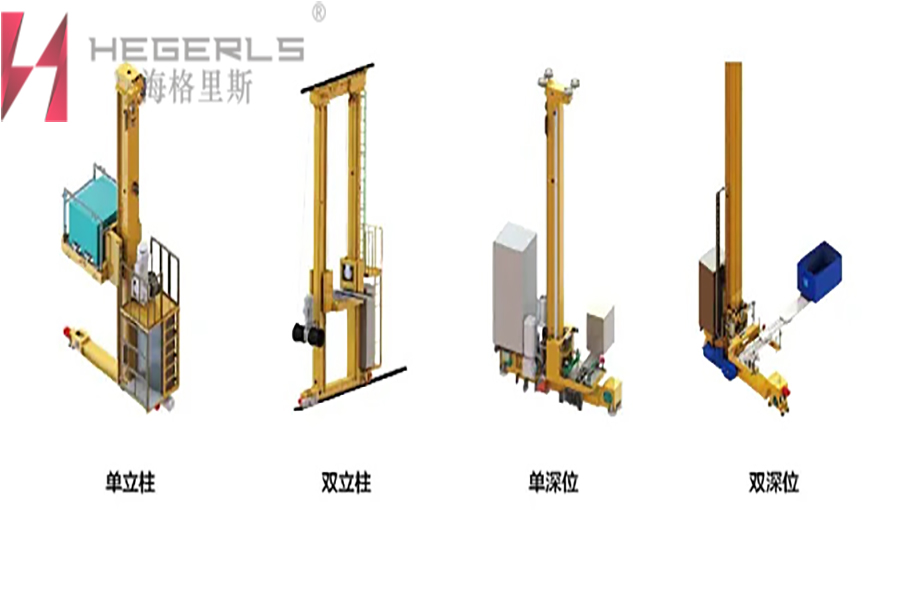

As / RS warehouse is an important part of modern logistics system and an elevated storage system for multi-layer storage and acquisition, including warehouse control system, shelves, robots, stackers and shuttle cars. Under the management of its computer WMS system, the warehouse can realize the automatic warehousing of goods and realize networking with the management system, which belongs to modern management measures. The stacker is the most important lifting and transportation equipment in the three-dimensional warehouse and the symbol representing the characteristics of the three-dimensional warehouse. Its main purpose is to operate in the channel of the three-dimensional warehouse, store the goods at the lane crossing into the goods grid, or take out the goods in the goods grid and transport them to the lane crossing.

The structural composition of the stacker includes: ground track, upper guide rail, cargo platform, operation panel and lifting motor, and the stacker is connected with the upper management system and control system to realize the automation of goods in and out of the warehouse. Infrared communication mode is adopted for stacker and three-dimensional shelf. There is no need to arrange too many wires between workshops, which has strong anti-interference ability. The single chip microcomputer belongs to the control system of the measurement and control center, which can timely issue response instructions to the upper management computer and establish communication with the upper computer in the shortest time.

Of course, in the context of rapid social and economic development, enterprises will be more concerned that under the requirements of high efficiency, the traditional inventory warehouse can no longer meet the requirements, but the application of stacker in automatic three-dimensional warehouse plays a key role. In this regard, Hercules Hergels storage shelf manufacturer will focus on the problems occurred in the use of stacker, and put forward solutions to these problems.

Of course, in the context of rapid social and economic development, enterprises will be more concerned that under the requirements of high efficiency, the traditional inventory warehouse can no longer meet the requirements, but the application of stacker in automatic three-dimensional warehouse plays a key role. In this regard, Hercules Hergels storage shelf manufacturer will focus on the problems occurred in the use of stacker, and put forward solutions to these problems.

Common faults and maintenance methods of stacker

Fault and abnormality of horizontal frequency converter

When the horizontal frequency converter fails, it is mostly due to the slow down or stop of the stacker caused by (overload, too fast deceleration, etc.).

The maintenance solution is: the stacker can be turned back to the original point, in the no-load and accurate stop state, and then reset.

Abnormal horizontal stop error

What is horizontal unsteadiness? In other words, it fails to jog to the stop position within the specified time or times.

The maintenance solution is: it can continue to operate after it can be reset occasionally; However, in case of continuous occurrence, it is necessary to check the holding brake or track of the horizontal motor.

Abnormal horizontal coding fault

The abnormal fault of horizontal encoder actually means that the reading of horizontal encoder is incorrect.

The maintenance solution is: if the level code is abnormal occasionally, it can be reset and continue to run; In case of continuous occurrence, it is necessary to check whether the encoder is loose, and then conduct teaching again after inspection.

Level teaching failure and abnormal fault

Horizontal teaching fails, that is, the number of columns when reaching the front end during teaching is inconsistent with the given maximum column.

The maintenance solution is to repeat the teaching or check whether the given number of columns is correct.

Fault and abnormality of horizontal front address recognizer

The maintenance solution is: when there is a failure of the horizontal front address recognizer, you can check the line, address recognition chip, replace the switch, etc.

Fault and abnormality of horizontal rear address recognizer

The maintenance solution is: when the fault of the horizontal rear address recognizer occurs, it is actually the same as the fault of the horizontal rear address recognizer. It is also necessary to check the circuit, address recognition chip, replace the switch, etc.

Rear speed limit switch fault is abnormal

The maintenance solution is: when the rear speed limit switch fails, we can check the circuit, remove the light board or replace the switch. At the same time, we also need to check the encoder of the stacker.

Front speed limit switch fault is abnormal

The maintenance solution is: the failure of the front speed limit switch is actually the same as the failure of the rear speed limit switch, that is, it is also necessary to check the circuit, remove the light plate or replace the switch, and check the encoder of the stacker.

Abnormal rear end switch fault | abnormal front end switch fault

The maintenance solution is as follows: in fact, when the rear switch fails and the front switch fails, the maintenance solution is the same as that of the rear speed limit switch failure and the front speed limit switch failure. It is also necessary to check the circuit, remove the light plate or replace the switch, and also check the encoder of the stacker.

Abnormal reverse fault of horizontal operation

What is horizontal operation reverse fault? That is, the direction of the pulse value of the horizontal pulse encoder is opposite to the direction of the given motion signal.

The maintenance solution is: we need to check whether the A and B lines of the pulse encoder are connected correctly, or whether the phase sequence of the power supply is correct.

The fault is abnormal after the stacker retreats to the last train

When the stacker retreats to the last column, this phenomenon is because at least one horizontal address recognizer of the stacker leaves the rear end of the address piece at the last column position.

The maintenance solution is: what we need to do is to check the horizontal band brake, address recognition device, address recognition piece, and the light removal plate of each address recognition device.

The fault in front of the largest train in front of the stacker is abnormal

What is in front of the stacker and in front of the largest train? In fact, it means that at least one horizontal address recognizer of the stacker is out of the back end of the address recognition chip at the forefront.

The maintenance solution is: what needs to be done is to check the horizontal band brake, address recognition device, address recognition piece, and the light removal plate of each address recognition device.

Turning speed limit switch fault is abnormal

The maintenance solution is: in fact, the literal meaning is also well understood. The maintenance solution is to check the circuit, speed limit board and replace the switch.

Stacker speed is too low and abnormal

The fault of low speed of stacker is abnormal, that is, the stacker cannot run in place for a long time after entering the address recognition chip.

The maintenance solution is: when such a fault occurs abnormally, what needs to be checked is the machinery, track or slightly increase the parking speed.

Fault and abnormality of horizontal Addresser

In fact, it is well understood that when any horizontal address recognizer fails or operates automatically, the stacker has run to the destination train, but the address piece has not been found within the specified error pulse range.

The maintenance solution is: when it can be reset occasionally, it can continue to run; However, in case of continuous occurrence, it is necessary to check whether the horizontal address recognizer is normal.

Level teaching failure and abnormal fault

The maintenance solution is: that is, the total number of columns defined horizontally is not consistent with the number of columns counted for teaching. When this fault is abnormal, it is necessary to check the total number of columns defined. The maximum column of roadway stacker is 100 columns and the horizontal address recognition chip, and whether the address recognition device can sense it.

Destination column error fault exception

The maintenance solution is: that is, the operation destination of the stacker is inconsistent with that issued. At this time, what needs to be done is to check the destination address of the distribution, clear the operation and re distribute the operation.

Vertical frequency converter fault and abnormality

The maintenance solution is: so what is the abnormal fault of vertical frequency converter? In fact, the protection of vertical frequency converter is caused by overload or too fast deceleration. The solution given by Hercules Hergels storage shelf manufacturer is to turn the stacker back to the original point, in the no-load and accurate stop state, and then reset.

Abnormal vertical stop error

The maintenance solution is: the so-called vertical stop inaccuracy means that the stacker exceeds the specified number of times during repeated low-speed rise and fall operation. The Hercules storage shelf manufacturer has also received feedback from cooperative customers on this abnormal problem. Based on many years of experience, the Hercules storage shelf manufacturer also has solutions to this problem. It is similar to some of the above problems. Similarly, when it occasionally occurs, it can be reset before continuing; However, if this fault occurs continuously, it is necessary to check the vertical motor holding brake or track.

Abnormal vertical coding fault

The maintenance solution is: this fault is abnormal, that is, the data read by the vertical encoder is not correct. When this abnormality occurs, or occasionally occurs, it can be reset and then continue to run; When this situation occurs continuously, it is necessary to check whether the encoder is loose, and then teach again after the inspection.

Vertical teaching failure and abnormal fault

The maintenance solution is: the vertical teaching fails, that is, when the teaching reaches the upper end, the number of layers is inconsistent with the given maximum layer; For this phenomenon, the manufacturer of hegerls storage shelf of hagris suggests that the given number of layers be taught or checked again, and whether the address recognition chip and vertical address recognizer of each layer can detect it.

Vertical upper (low | high) addresser fault is abnormal

The maintenance solution is: when this fault is abnormal, it is necessary to check the circuit, remove the light board or replace the switch, and also check the editor of the stacker.

Upper speed limit | lower speed limit switch fault is abnormal

The maintenance solution is: the upper speed limit and lower speed limit switches are abnormal, which is well understood. The solution is to directly check the circuit, remove the light plate or replace the switch. Of course, the encoder of the stacker should also be checked at the same time.

Abnormal reverse fault of vertical operation

The maintenance solution is: this fault is that the direction of the pulse value of the vertical pulse encoder is opposite to the direction of the given motion signal; During its maintenance, the staff shall check whether the A and B lines of the pulse encoder are connected correctly, or whether the phase sequence of the power supply is correct.

The rope loosening protection fault of speed governor is abnormal

The maintenance solution is: when there is a fault in the loose rope protection of the speed governor, be sure to check whether the steel wire rope of the speed governor is loose. If so, the staff need to check and repair.

The fault under the address recognition chip of the lowest layer and the highest layer of the pallet is abnormal

The maintenance solution is as follows: in fact, the lower end or upper end of the address recognition piece appears in both the address recognition devices on the cargo platform at the bottom or the top. The solution is to directly check the vertical holding brake, address recognition device and address recognition piece.

Vertical overspeed fault abnormality

The maintenance solution is: the said vertical overspeed fault is abnormal, that is, the detected actual speed exceeds the specified range of the given speed. The manufacturer of hegris hegerls storage shelf recommends checking the vertical motor wiring and holding brake.

Vertical addresser fault exception

The maintenance solution is as follows: the fault of the vertical address recognizer is abnormal, that is, when any vertical address recognizer fails or runs automatically, the pallet has run to the destination layer, but the address piece has not been found within the specified error pulse range. What the enterprise should do is to check whether the switch and circuit are damaged or whether the switch and address recognition chip cooperate.

Fork locked rotor fault is abnormal

The maintenance solution is: many enterprises may have encountered this fault problem, that is, the fork is not extended (retracted) in place within the specified time. When this problem occurs, we need to check whether there are obstacles on the fork extension route or whether the fork mechanism is loose; When pressing the Green function key to clear the fault, then press the extension fork and operate repeatedly until the fork stops accurately.

Upper fork detection switch fault abnormal

The maintenance solution is: that is, when the fork has a middle position, at least one upper fork middle position detection switch has no signal, or the upper fork does not receive the middle position; In case of failure of the upper fork detection switch, it is necessary to check whether the switch and circuit are damaged, or whether the switch is matched with the impact ruler. At the same time, it is also necessary to check whether the fork has returned to its original position.

Fork neutral stop switch fault is abnormal

The maintenance solution is: when the fork middle stop switch is abnormal, it is necessary to check whether the switch and circuit are damaged or whether the switch and impact ruler cooperate.

Fork left probe | right probe switch fault is abnormal

The maintenance solution is: when the left or right detection switch of the fork fails, it means that the left or right detection switch of the fork cannot normally detect the pallet. At this time, what we need to do is to check whether the switch and circuit are damaged or directly adjust the fault of the detection switch.

Left | right skew detection switch fault abnormality

The maintenance solution is: when the left | right skew detection switch is abnormal, check whether the switch and circuit have been damaged and whether the switch and reflector cooperate.

The cargo detection switch of the pallet is faulty or abnormal

The maintenance solution is: when the cargo detection switch of the loading platform has abnormal fault, it is necessary to check whether the switch and circuit have been damaged and whether the switch and reflector are matched.

Inching timeout fault abnormality

The maintenance solution is as follows: when the pallet does not rise to the high position when picking up the goods or does not fall to the low position when storing the goods within the specified time, the staff should first check whether the address recognizer switch is damaged or whether the switch and the address recognizer are matched.

Abnormal loose protection rope fault

The maintenance solution is: when the steel wire rope is loose or broken, observe whether there is a false alarm and contact the technical support personnel.

Overload protection fault abnormality | cargo superelevation fault abnormality

The maintenance solution is: when the goods are overweight or ultra-high, it is necessary to sort out the goods before running again.

Abnormal long cargo fault

The maintenance solution is as follows: the fault phenomenon of over long goods is that when the stacker releases goods at the end point, it will detect that there are goods on the conveyor. When this phenomenon occurs, it is necessary to remove the corresponding goods in front of the conveyor and press the reset button to reset.

Fork overheat protection fault abnormal

The maintenance solution is: This is because if it is operated for a long time or overloaded, it will lead to thermal relay protection of the fork. If this happens, open the control cabinet and press the red contact of “fr” thermal relay.

Teaching mode fault is abnormal

The maintenance solution is: when the teaching mode fails, the maintenance solution is to power off and restart after the teaching, and then press the reset solution to solve this problem.

There is abnormal operation fault during startup

The maintenance solution is: there is an operation during startup, that is, one operation is retained after shutdown, so how to solve this situation? Of course, you can press the function key to reset or clear the current job.

Fault of high pallet entering the wrong location is abnormal

The maintenance solution is: the so-called high pallet entering the wrong location is that the operation displays the low location and the pallet goods are too high. In this case, it is necessary to re issue the operation and then re load the goods.

Abnormal cargo skew / over width fault

The maintenance solution is: the goods are skewed or ultra wide, which actually refers to the skew of the pallet goods. When this phenomenon occurs, it is necessary to sort out the pallet goods and check whether the detection switch is faulty.

Stacker blind code fault abnormality

The maintenance solution is: the so-called stacker blind code means that the scanner does not scan the bar code. The suggestion given by Hercules Hergels storage shelf manufacturer is to scrub the scanning switch and then check the bar code.

Abnormal communication with conveyor

The maintenance solution is: when there is a communication failure with the conveyor and the machine cannot move, the first thing to check is whether the line is connected.

There is no pallet fault exception in the job queue

The maintenance solution is: some enterprises may have really encountered the phenomenon that there is no such pallet in the operation queue. When this happens, they can take out the pallet first, and then put the pallet after issuing the operation.

The current pallet enters the wrong roadway, and the fault is abnormal

The maintenance solution is: when the current pallet enters the wrong roadway and fails, it needs to put the pallet again.

There is no fault or abnormality in picking up

The maintenance solution is to check the status of the cargo location directly when there is picking up or no container.

Double warehousing fault exception

The maintenance solution is: when there is a double warehousing fault, what needs to be done is to check the location status or directly detect the switch.

Illegal operation | destination layer fault exception

The maintenance solution is: when these two situations occur, what we need to do is to reissue the operation.

Wrong tray number, abnormal fault

The maintenance solution is: generally, if the scanned pallet number is different from the operation pallet number, or if the pallet is not scanned, the operation also needs to be reissued.

Conveyor operation timeout | emergency stop fault abnormality

The maintenance solution is: when the conveyor runs overtime or there is an emergency stop, just press the reset key.

Air switch detection fault abnormality

The maintenance solution is: when there is air switch detection fault, it is necessary to check whether the switch and circuit are normal.

Pallet in / out conflict fault exception

The maintenance solution is as follows: when the conflict and abnormal failure of pallet in and out of the warehouse occur, what we need to do is to adjust the in and out of the warehouse.

Pallet size fault abnormal

The maintenance solution is: when the tray size is abnormal, just adjust the tray position.

Tray superelevation | left superwidth | right superwidth fault abnormality

The maintenance solution is: when the pallet has super height, left super width and right super width, it needs to directly re code the goods.

Abnormal communication with stacker

The maintenance solution is: when using the stacker, there will be communication failure with the stacker and the pallet will not move. At this time, stop and check whether the line is connected.

Post time: May-23-2022