As a provider of next-generation smart logistics products and solutions, Hebei Woke, based on AI native algorithm capabilities and a one-stop platform for robots, continues to create industry benchmark cases and provide efficient and intelligent warehousing and logistics solutions for many enterprise customers. Hebei Woke Metal Products Co., Ltd. is a professional manufacturer of automated three-dimensional warehouse design and equipment. It is a professional manufacturer of shuttle trucks and stackers, committed to providing customers with cost-effective automated three-dimensional warehouse planning and overall equipment solutions. As a professional manufacturer with technology patents related to automated three-dimensional warehouses, Hebei Woke has provided more competitive prices and excellent services for hundreds of three-dimensional warehouses, such as cost-effective intelligent logistics equipment and management systems. Automated three-dimensional warehouses serve

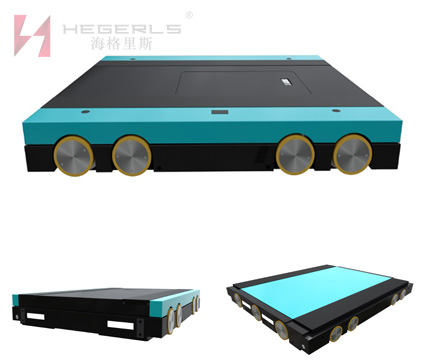

customers from various fields such as chemical, food, medical, mechanical, and cold storage. The main products of three-dimensional warehouses include: aisle stackers, intelligent shuttle cars, multi-layer shuttle cars, parent-child shuttle cars, four-way shuttle cars, elevators, AGV/RGV cars, etc. Hebei Woke's main products are various high-precision industrial shelves, intelligent robots for automatic storage and retrieval of goods, and cloud based warehouse management software. We provide customers with "robot+shelf" intelligent warehousing solutions, meeting their different warehousing needs for material boxes or pallets, running through the production and warehousing processes, providing more warehousing options.

About Hebei Woke HEGERLS Four Way Shuttle

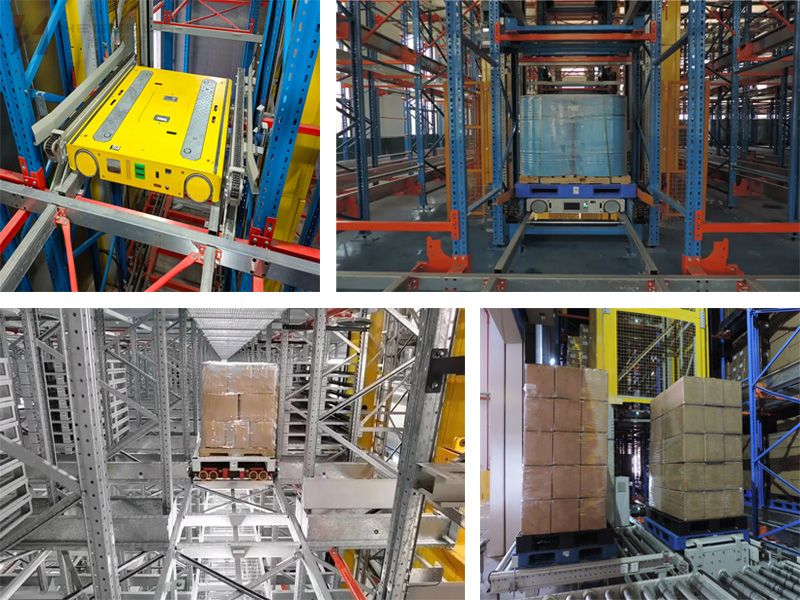

The four-way shuttle vehicle three-dimensional warehouse is considered one of the effective solutions for automated three-dimensional warehouses due to its advantages of high density intelligent storage and systematic management. Especially for large automated three-dimensional warehouse systems, the HEGERLS four-way shuttle has high flexibility and flexibility, which can be linearly adjusted by increasing or decreasing the number of vehicles or lifting machines, ensuring that the operation capacity and efficiency of the three-dimensional warehouse are not greatly affected.

The HEGERLS four-way shuttle vehicle three-dimensional warehouse system integrates storage and picking, which is suitable for low flow and high-density storage, as well as high flow and high-density storage and picking. Compared to traditional stacker crane three-dimensional warehouses, storage and operation space should be reserved for each cargo. The four-way shuttle vehicle three-dimensional warehouse can minimize such non storage space, achieve the highest density storage, and increase the storage capacity by more than 20%.

The Hebei Woke HEGERLS four-way shuttle can move across alleys and floors, and each Hebei Woke HEGERLS four-way shuttle can reach any cargo compartment on the shelves in the system. Therefore, when a certain Hebei Woke HEGERLS four-way shuttle fails, it will not have a significant impact on the overall operation of the system; At the same time, due to the fact that the number of equipment is no longer limited by lanes and layers, the HEGERLS four-way shuttle system can flexibly increase or decrease the number of HEGERLS four-way shuttle vehicles according to the system throughput requirements.

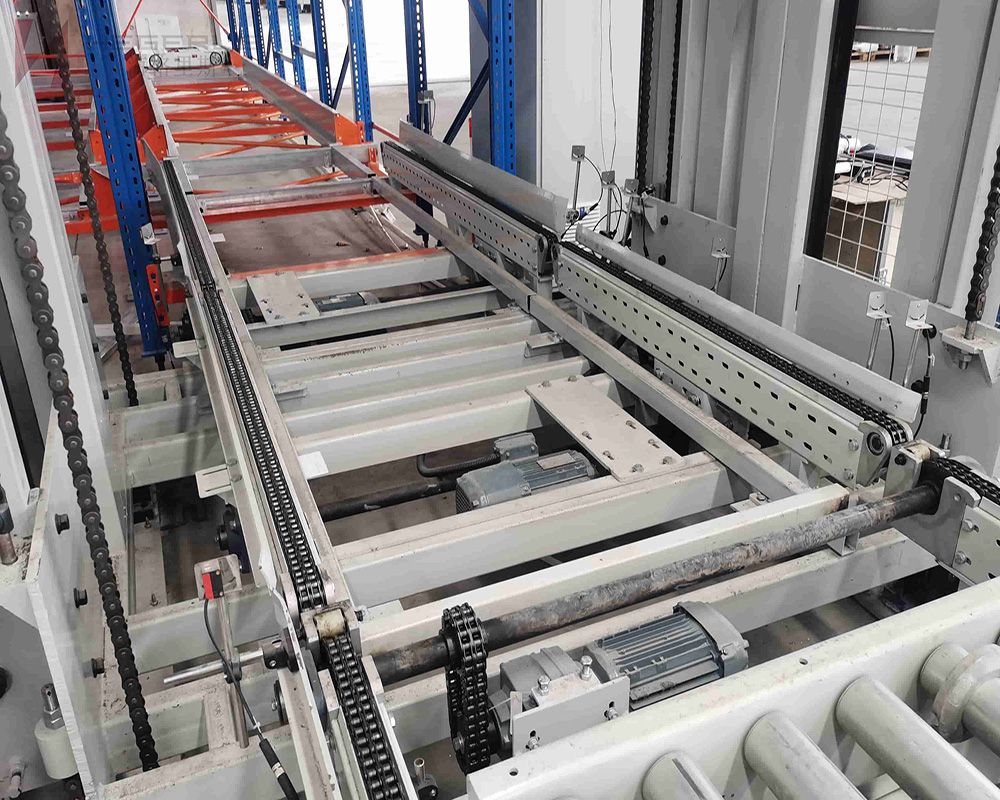

The HEGERLS four-way shuttle operates in four directions on the main track inside the rack, and can complete operations independently without the need for coordination between forklifts and other equipment. As the volume of the main track on the rack is smaller than that of the forklift operation channel, it can further improve the utilization of storage space. The HEGERLS four-way shuttle is an advanced automatic Material-handling equipment, which not only enables the automatic storage and retrieval of goods in the warehouse according to the need, but also can be organically connected with the production links outside the warehouse, facilitating the formation of an advanced logistics system, improving the enterprise management level mode, reducing the workload of warehouse personnel, providing the possibility of unmanned work in the warehouse, and realizing the storage and retrieval automation, No personnel are required to enter the warehouse for operations, especially suitable for warehouses such as cold storage that are not suitable for long-term personnel residence. It is the development direction of high-density dense storage and automated warehousing in the future.

Post time: Jun-14-2023