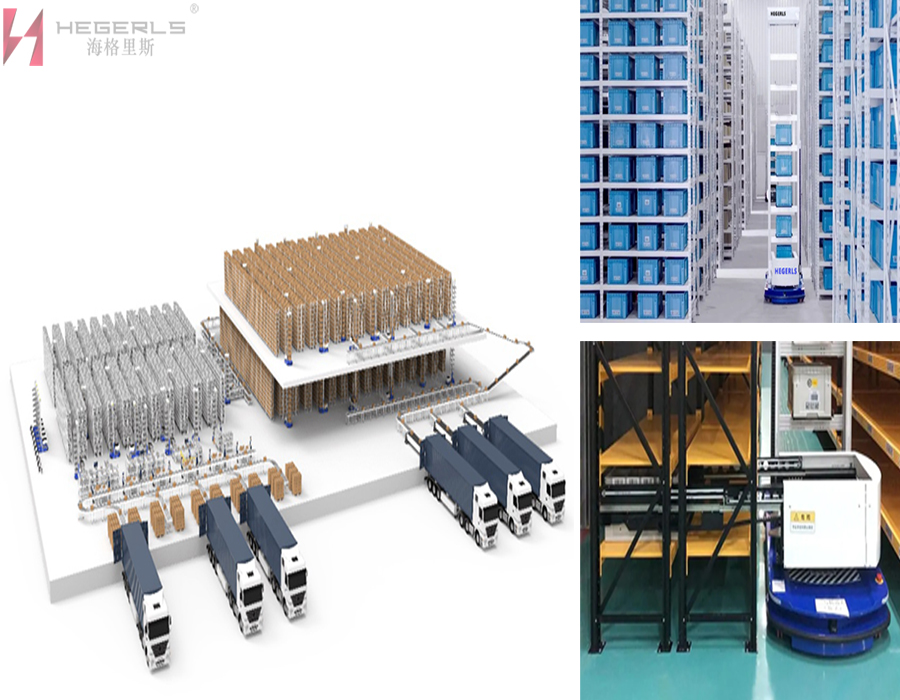

The high warehouse rent cost has always been a big pain point for warehousing and logistics enterprises. Hagris has further created value for customers and officially launched the double deep box storage robot hegerls a42d, which can realize commercial landing projects, to improve the utilization rate of storage area for customers and realize high-density storage. As the first dual deep bin robot at home and abroad, kubao hegerls a42d is specially developed to solve the problem of storage density.

Hegerls a42d, independently developed by hagris, is a dual deep position bin robot that is the first in foreign countries. It has a dual deep position picking function. While maintaining the flexibility of the autonomous mobile robot, it greatly optimizes the storage density of the warehouse and provides a unique automated warehouse solution. Hegerls a42d, a double deep position bin robot, provides the market with a brand-new innovative technology. It has been rated as “technology innovator” because it “changes the innovation of warehouse operation, improves warehouse operation efficiency, and is easy to deploy, maintain and operate”.

Kubao robot independently developed by haggis is the first box type storage robot developed and realized commercial landing, and has opened up the subdivision fields of “container robot” and “container robot”. After continuous iteration and technological innovation, kubao’s product line has become increasingly rich, covering a variety of products, including the multi bin robot herls A42, the double deep bin robot herls a42d, the carton sorting robot herls a42n, the telescopic lifting bin robot herls a42t, and the laser slam multi-layer bin robot herls A42 slam, to solve the storage pain points, help enterprises improve the efficiency of warehousing operations, reduce operating costs, and achieve the upgrading of warehousing automation.

About hegerls a42d double deep position bin robot

Hegerls a42d double deep position material box robot can realize intelligent picking and storage of material boxes and simultaneous handling of multiple material boxes (the maximum load of a single trip can reach 300kg). On the basis of the hegerls a42d multi-layer bin robot, the independently innovative research and development of the extended telescopic fork can realize the double deep position picking and placing bin of the shelf and significantly improve the storage density. As a new intelligent logistics handling equipment, hegerls a42d can realize intelligent walking in the storage space without the help of any track equipment. It has the functions of autonomous navigation, active obstacle avoidance and automatic charging. Compared with the traditional AGV “shelf to person” solution, the hegerls a42d double deep bin robot has smaller picking granularity. According to the order requirements issued by the system, it truly realizes the transformation from the traditional “people looking for goods” to the efficient and simple “goods to person” intelligent picking mode. Compared with the solutions of stacker and automatic three-dimensional warehouse, the hegerls a42d dual deep bin robot system can be deployed efficiently, with low overall deployment cost and stronger flexibility; At the same time, hegerls a42d supports docking with a variety of logistics equipment, including shelves, latent AGVs, robotic arms, multi-function workstations, etc. The flexible and flexible product design brings more operating space for the customized scheme, comprehensively improves the storage operation efficiency, optimizes the storage density, and realizes the automation and intelligent transformation of the storage industry. Applicable scenario: applicable to warehousing applications in 3PL, shoes and clothing, e-commerce, electronics, electric power, manufacturing, medical, retail and other industries.

Features of hegerls a42d double deep position bin robot

Hegerls a42d double deep bin robot has a customizable telescopic fork, which can realize the simultaneous picking of deep and shallow bins, support the use of 5m double deep shelves in the warehouse, effectively reduce the roadway area by up to 50%, and increase the storage density by 130% compared with the traditional manual warehouse. Based on the intelligent algorithm optimization provided by the intelligent management platform, hegerls a42d adopts a new picking method and location strategy to effectively ensure the operation efficiency and realize the dual optimization of storage density and storage efficiency. At the same time, the overall solution can match the business scenario, realize the intelligent picking, handling and storage of multiple bins, optimize the operation process and improve the storage efficiency.

Functional characteristics and advantages of hegerls a42d double deep position bin robot

Ø30% UP! Ultimate density

Hegerls a42d adopts double deep shelves to effectively reduce the number of lanes and improve the utilization of storage space. Compared with the single depth system A42, the storage density can be increased by 30%.

Ø long arm giant, double deep access

Hagerls double deep position system a42d has reformed the telescopic fork on the basis of the original A42, so that the double deep position robot can take and place the containers of shallow and deep positions at the same time. Based on the algorithm scheduling of haiq software platform, it realizes intelligent storage and independent picking, with both storage density and efficiency.

Ø intelligent optimization, double depth strategy

Due to the inherent principle of “first in, last out” (Filo) of double depth shelves, the traditional double depth automatic equipment can only take and place goods at the same time or use the method of goods pouring operation to take and place goods. The dual deep location hagerls a42d system configures intelligent location optimization strategies for different business scenarios:

cold and hot storage location sorting operation strategy

operation strategy of associated warehouse location sorting

Hagris team has customized the simulation system for the double depth scenario, combined with the optimization strategy, customized and efficient simulation for customer projects, and provided the optimal double depth solution. Hagris always takes the success of customers as its mission, and is determined to solve the storage pain points for customers and create value. Kubao series products are the core competitiveness of Hagrid, and constantly improving product quality, stability and performance is Hagrid’s persistence and commitment to customers. Adhering to the concept of win-win cooperation, hagris welcomes the majority of logistics enterprises to join hands with us to create value for customers.

Post time: Jun-29-2022