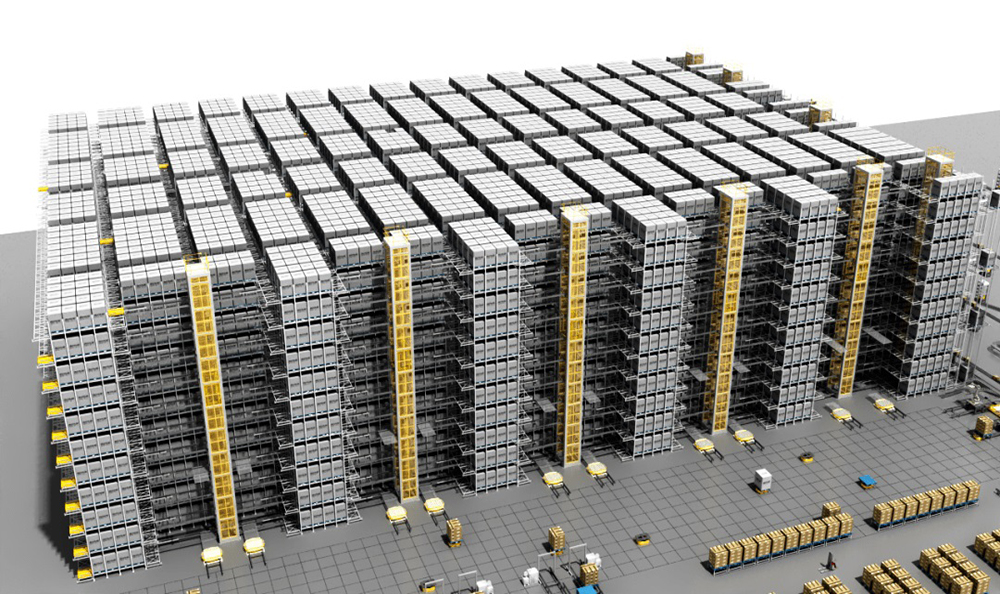

The four-way shuttle vehicle three-dimensional warehouse is a common automated three-dimensional warehouse solution that can be applied to irregular, irregular, large aspect ratio or small variety large batch, multi variety large batch warehouses. Its core equipment, the four-way shuttle, overcomes the shortcomings of the circular shuttle and has high flexibility and flexibility. For large three-dimensional warehouse systems, the four-way shuttle has a high cost-effectiveness, which can be improved by increasing the number of small cars and improving the level of entry and exit. Regardless of the small or large outbound volume, the four-way shuttle truck three-dimensional warehouse solution is very suitable.

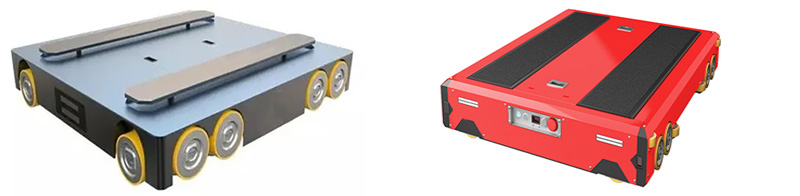

According to different loads, the four way shuttle cars on the market can be divided into two types: pallets and bins. The pallet four way shuttle can carry hundreds of kilograms or even more of cargo, while the container four way shuttle can carry dozens of kilograms of container cargo. The structural form and control method of the two are basically similar, mainly due to differences in design details and application scenarios.

The core equipment of the tray four-way shuttle type automated dense storage system includes tray four-way shuttle cars, dedicated vertical elevators, and supporting shelves. The tray four-way shuttle car has a compact structure, fast running speed, and adopts wireless communication. Multiple tray four-way shuttle cars work in a formation shape, which can cooperate and meet the application needs of different places. The pallet four-way shuttle car can not only travel in four directions on the supporting shelf tracks, but also use vertical elevators to achieve layer changing operations inside the shelves, improving the flexibility of shelf layout and warehouse operations.

The Hagrid HEGERLS intelligent logistics intensive shuttle garage, combined with intelligent transportation systems, palletizing systems, and layer changing systems, can meet most forms of dense pallet storage, supporting low level shelves. It adopts shuttle board+AGV (forklift) mode, sub mother shuttle board mode, and stacking sub mother car mode, which is flexible and variable. It supports high and low level shelves, and automates low level pallet warehouses with height restrictions, It is a good solution.

So what are the core technologies of the Hagrid HEGERLS tray type four-way shuttle system?

Core Technology 1 of HEGERLS Tray Four Way Shuttle System

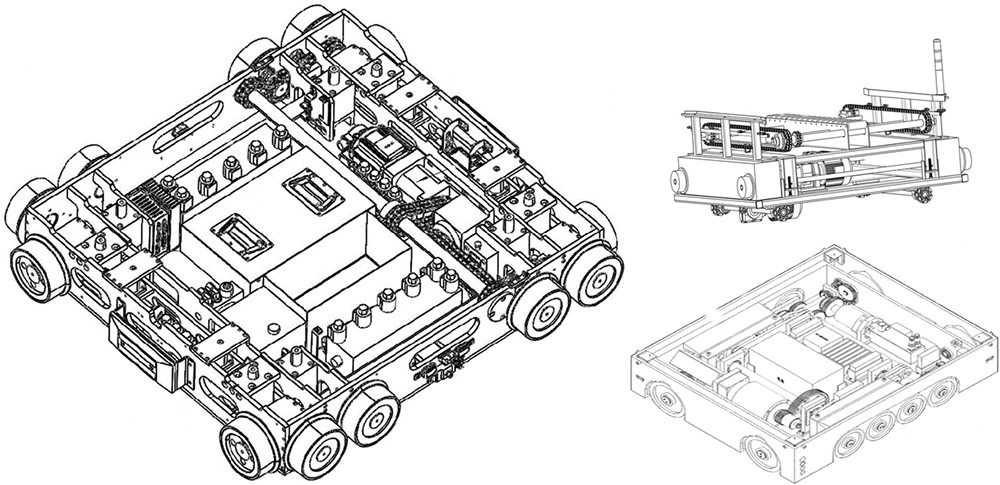

The most important core of the tray four-way shuttle vehicle system lies in the reliability of hardware, communication and positioning technology, scheduling system, etc. In terms of hardware reliability, each HEGERLS shuttle vehicle body is equipped with multiple sensors, mainly used for collision prevention, tray detection, walking wheel angle monitoring, etc., to ensure real-time understanding of vehicle operation.

HEGERLS Tray Four Way Shuttle System Core Technology II

The most technological and intelligent aspect of the core technology of the tray four-way shuttle vehicle system is the rail changing technology. The track changing mechanism is a key part of completing the reversing operation of the entire vehicle. Taking into account the stability and reliability of the vehicle structure and the safe and reasonable layout of each structural module, the Hagrid HEGERLS adopts a "vehicle on track lifting, dual side synchronous reversing" mode. That is, when reversing operation, it needs to be moved down by the reversing body installed in the lower part of the frame, and the dual side driving motion module fixed to the reversing body gradually contacts the 90 ° reversing track, The lifting mechanism continues to lift the entire vehicle to a certain height, which in turn drives the dual side driving motion module that is fixedly connected to the vehicle to move up and away from the original motion track, completing the vehicle's reversing operation and achieving stable reversing.

HEGERLS Tray Four Way Shuttle System Core Technology III

The most critical and most enterprise customers' concern for the tray four-way shuttle system is the problem of troubleshooting. The research and development team and technical personnel of HEGERLS have also considered and proposed solutions to this issue, including a reasonable one click recovery solution for software failures, a disaster preparedness plan for hardware recovery, such as emergency backup power supply, fault rescue vehicles, manual troubleshooting of walking isolation networks, and a certain reserve of spare vehicles for customers. This can not only deal with abnormal situations in customer inbound and outbound orders, but also handle them, At the same time, it is also possible to replace faulty vehicles in a timely manner.

The Hagrid HEGERLS pallet four-way shuttle truck can greatly reduce the dependence of shuttle shelves on stackers, elevated forklifts, and other supporting equipment. It can also significantly improve the access efficiency of ordinary shuttle storage systems, improve the operational safety of warehousing operations, and optimize the structure of the shuttle storage system. It effectively combines the storage channel of materials with the transportation channel of materials, not only strengthening the stability of the shelves, It can also make each material storage location a dynamic logistics management location, reduce the construction cost of shuttle warehousing, improve the space utilization rate of the warehousing system, and deepen the development concept of intensive, intelligent, and automated warehousing systems.

Post time: Sep-11-2023