Drive in shelf refers to the storage of pallets one by one from inside to outside. The same channel is used for forklift access, and the storage density is very good. However, due to poor accessibility, it is not easy to implement FIFO management. Since the forklift must operate carefully when walking in the whole rack, it is better to drive into the rack with 4 layers and 3 to 5 columns.

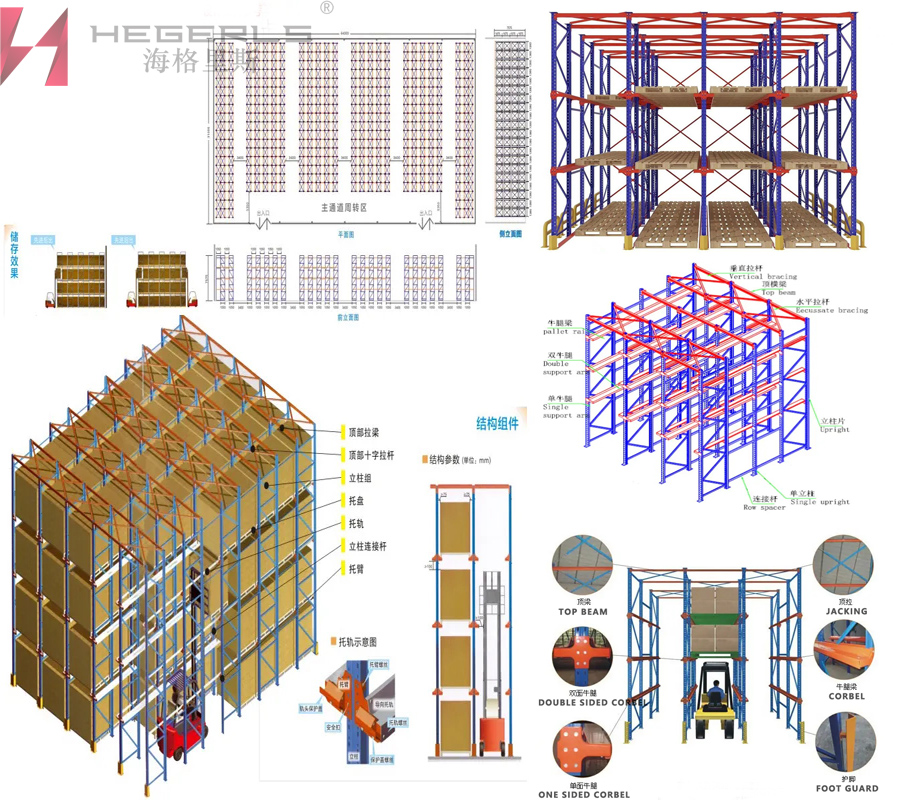

Drive in rack composition

The accessories of the drive in rack include: corbel (the main connector between the corbel and the rack column, single side and double side), corbel (the main support shelf for goods storage), top beam (the connector and stabilizer of the rack column), top pull (the connector and stabilizer of the rack column), back pull (the connector and stabilizer of the rack column, used for one-way rack layout), foot guard (the front protective part of the rack) Guard rails (protective parts of shelves when forklifts enter the roadway), etc.

Specifically, the drive in rack, also known as corridor rack and through rack, is a multi door rack structure that connects several rows of traditional racks or lattice column structures in a continuous way without channel division and continuity, and the pallet is stored on the cantilever beam in a unit and stored in the depth direction; This kind of shelf has the characteristics of the largest storage capacity of goods per unit volume, and is suitable for the storage and operation system of materials with large batch, few varieties and large flow, such as beverages, dairy products, low-temperature refrigeration storage, household appliances, chemicals, clothing, tobacco and other occasions with high cost of storage space, but it is not suitable for the storage of items that are too long or too heavy; Compared with the traditional tray cross beam shelf structure, the space effective utilization rate of the drive in shelf can be increased to 90% at most, and the site utilization rate can also reach more than 60%, which can achieve the maximum loading density. In the actual application process, the drive in shelf can also be used in combination with other multi category shelf structures to fully meet the various storage requirements of the customer’s site.

So, how do we buy the drive in shelf before daily use? Now, let’s follow the manufacturer of Higelis shelf to find out!

The purchase of drive in shelves requires a clear understanding of the pallet unitization of stored items

The structure and size of the drive in shelf are determined by the storage items, handling equipment and pallet unit size; Due to the large storage density and high turnover efficiency of the drive in shelf storage area, the steel structure of the shelf is close to the operation and storage channels. Compared with other types of shelves, there are more detailed specifications and higher quality requirements for the pallet and pallet unit. It is necessary to make effective selection according to the force characteristics of the pallet, especially for long-span pallets, the static and dynamic load of the pallet must be checked Load on shelves and the way goods are placed on pallets; At the same time, the shelf of this category also has high requirements on the unit packaging of goods, so as to reduce the damage rate of stored goods and improve the efficiency and safety of shipment; The pallet unitized goods should not be too large or too heavy. Generally, the weight should be controlled within 1600KG, and the pallet span should not be greater than 1.5M. In addition, through the unitized packaging classification of stored goods, heavy load and large floor height goods should be stored in the lowest storage position of the drive in shelf structure as far as possible, which can effectively reduce the storage center of gravity of the shelf system and improve the storage and stability of the system.

The purchase of drive in shelf lattice vertical structure also depends on lattice column structure

The lattice column structure designed, produced and manufactured by the Higelis shelf manufacturer is also the most common structure in the drive in shelf structure. It is mainly composed of column limb (frame column) and web member (cross brace and diagonal brace). The column limb mostly adopts uniaxial symmetric cold-formed thin-walled perforated section steel column. The web member mostly adopts cold-formed steel of C-shaped section. The column limb and web member are connected by bolts to form a single diagonal bar lacing structure. The pressure of the frame column is due to the cross The diagonal braces share a part of the structure and are slightly reduced. The whole structure is safer without considering the positive effects of transverse braces and diagonal braces; The typical structure of the column limb is a uniaxial symmetric cold-formed thin-walled perforated section steel column component. When bearing the load capacity, it is prone to bending and torsional buckling, which reduces the bearing capacity. You can add battens on the open side to make it close to the closed section, which can greatly improve its bearing capacity. The X-X bending stability of this type of component directly determines the bearing capacity and structural stability of the drive in shelf. Similarly, this lattice column structure is also the side column of the portal structure of the drive in shelf. Because the bending stiffness and torsional stiffness of the portal frame structural members are small, the overall stiffness of the structure is weak. The higher the height, the lower the bearing stability, and the ability to resist bending and torsional buckling will be significantly reduced. The cantilever arm length parameters and the weight of the bearing tray are the direct actors that exert bending torque on the lattice column structure, The additional bending torque generated along with the length of the cantilever affects the bending and torsional strength of the rack column.

At present, the analysis of the system structure frame is replaced by the calculation of the strength, stiffness and stability of the lattice column in the design of the drive in shelf. Because the lattice column is generally composed of thinner and thinner components, the stiffness and stability of the column structure in the drive in shelf structure are greatly affected by its slenderness ratio, its structural stability is weak, and there are few structural reinforcement modes that can be realized, It is also difficult to achieve. At present, the market optimizes the operation channel by using WAP shuttle trucks to replace the entry and exit tunnel operation mode of other handling equipment such as forklifts, and it can facilitate the horizontal beam reinforcement of the frame column at the effective part below the storage location, which can greatly optimize the slenderness ratio of the frame column; Or in the innermost cargo space of the entry and exit roadway, the design of the drive in shelf structure is optimized through the typical structure of the pallet beam shelf, so as to improve the bearing capacity and stability of the shelf structure as a whole, which will also become one of the main methods for the optimization of the drive in shelf structure in the future.

Post time: Sep-19-2022