【Project Name】High Position Heavy Beam Shelf Project

【Construction unit】 Hebei Woke Metal Products Co., Ltd

【Cooperative client】A large group in Shenyang, China

【Construction Time】 Early May 2023

【Construction area】 Shenyang region, China

【Project Customer Requirements】

One of the largest manufacturing enterprises in China’s transformer industry and an important transformer product manufacturing, research and development, and export enterprise in a large group in Shenyang, which is cooperating with the Shenyang High Position Heavy Beam Shelf Project. The company has the only national engineering laboratory in the transformer industry in China, and is the backbone enterprise with the longest history, largest scale, and strongest technical strength in the industry. It is also an important research and development base for ultra-high voltage, large capacity, and DC transmission products in China. Because the group belongs to a major equipment manufacturing industry, its materials are mostly heavy mechanical products such as large physical raw materials, semi-finished parts, and finished equipment. Storage products have certain particularity, as well as high requirements for the safety and reliability of storage equipment. At the same time, there are many types of products and frequent entry and exit, which is not conducive to staff accessing goods, and so on. In order to improve the management level of enterprise products and the work efficiency of company employees, intelligent storage areas of different specifications are constructed based on the distribution of product output and storage needs. The group hopes to provide matching sorting equipment suitable for storage scale for product materials.

【Project Specific Overview】

In 2023, a large group in Shenyang compared multiple warehousing and production providers based on their own product needs. They called Hebei Woke Metal Products Co., Ltd. and hoped that our company (Hebei Woke Metal Products Co., Ltd., self owned brand: HEGERLS) could provide a storage and warehousing warehouse shelf solution suitable for large material items such as transformers. Our company (Hebei Woke Metal Products Co., Ltd., self owned brand: HEGERLS) sent the project leader, Manager Chen, to the group for on-site inspection. After arriving at the site, we conducted surveys and measurements, and recommended site planning, scheme design, and suitable shelf selection for customers. Based on the actual data of the group’s product raw material characteristics, warehouse location, and other factors, after discussing with the design team and also communicating with the customer to confirm the plan, it was ultimately decided to provide a set of high level crossbeam shelf solutions for the group.

High level crossbeam shelves, also known as cargo pull shelves, adjustable pallet shelves, and selective shelves, belong to high level heavy-duty shelves and are one of the more common types of shelves. Their structure is simple, safe, and reliable. Its structure is that the shelves are divided into several rows along the width direction of the warehouse, with a port passage between them for the operation of stacking cranes, forklifts, or other handling machinery. Each row of shelves is divided into several columns along the longitudinal direction of the warehouse, and in the vertical direction, it is further divided into several layers, forming a large number of cargo spaces for pallet storage of goods.

One of the characteristics of high level crossbeam shelves is “high”, which can fully utilize the upper warehouse space to load a lot of goods, thereby achieving large-scale storage needs. One major advantage of the high beam type shelf is that it is more suitable for using mechanized and automated equipment for operations, allowing for faster and more accurate execution of various work operations.

The high level crossbeam type shelves must undergo unitization work, which involves grouping the packaging and weight characteristics of the goods, determining the type, specification, size of the pallets, as well as the single pallet weight and stacking height (the weight of single pallet goods is generally within 2000KG). Then, the span, depth, and layer spacing of the unit shelves are determined, and the height of the shelves is determined based on the height of the lower edge of the warehouse shelves and the large fork height of the forklift. When used in conjunction with pallets or other carrying and operating equipment, it provides accessibility and has good picking efficiency, suitable for various types of forklift access. It can be adjusted and combined at will, safe and simple, economical and practical. The high level crossbeam type shelf is an assembled structure with integral connection and insertion combination, and safety pins are added to ensure the fixation of the columns and crossbeams. The high level crossbeam type shelf is mainly composed of a combination of heavy columns, crossbeams, pallets, and forklifts. Its accessories are made of Q235B steel, which is flattened, rolled, punched, and then cut to a specified length. This length can be designed according to customer needs. At the same time, functional accessories such as partition, steel plate (steel grating), wire mesh layer, storage cage guide rail, oil drum rack and so on can be added according to the characteristics of the storage unit container equipment, which can meet the cargo storage of different unit container equipment forms. Hebei Woke (self owned brand: HEGERLS) can customize dimensions according to the actual usage of users, such as pallet load requirements, pallet size, actual warehouse space, and actual lifting height of forklifts to lift different specifications of crossbeam high level storage shelves.

Specific structure of high level crossbeam type shelves

Posts: The cross beam rack (cargo space rack) is composed of two columns, cross braces and slant support connected by nylon self-locking bolts. The combined structure is effective to prevent the instability of the rack caused by loose bolts. The column is punched with double rows of rhomboid holes with a pitch of 75mm or 50mm. Therefore, the cross beam can be freely adjusted up and down in the unit of 75mm when it is attached to the column. The column section is composed of 11 to 13 faces, with a large inertia distance, strong load-bearing capacity, and strong impact resistance. The crossbeam type shelf column adopts automatic punching followed by cold bending forming technology, avoiding the possibility of crack failure caused by column stress concentration. To prevent collisions with forklifts, etc., it is generally equipped with pillar protection.

Cross beam: The crossbeam type shelf (cargo space shelf) is composed of two column clamps welded together with the crossbeam rod. The crossbeam is welded with two specially made shaped welding beams, which thickens the thickness of the upper and lower parts of the crossbeam. This structure, based on the design theory of steel structure, fully utilizes the load-bearing capacity of the material, and has the characteristics of light weight, strong bearing capacity, and low cost. When connecting the crossbeam to the column, a specially designed safety pin with ear pieces is equipped. The safety pin with ear pieces cannot be easily pulled out, which can ensure that the crossbeam will not fall off after external force impact.

Characteristics of high level crossbeam shelves:

1) The structure is simple, safe and reliable, and can be adjusted in any combination (with the ability to freely adjust the height of each layer by an integer multiple of 75mm). The entry and exit are not limited by the order of items, and are widely used in storage modes such as pallet storage and forklift access.

2) The high level crossbeam shelves adopt a plug-in combination form and are fixed with safety pins. They have high load-bearing capacity, are not easily deformed, are connected reliably, are easy to disassemble, and are diversified. The surfaces of all shelves are treated with acid washing, phosphating, electrostatic spraying, and other processes to prevent corrosion and rust.

3) The standard shelf pillars adopt automatic punching followed by cold bending forming technology, avoiding the possibility of cracking and failure due to stress concentration on the pillars; Its feet can be equipped with column foot guards and collision bars to prevent forklift collisions; It is also possible to place auxiliary facilities such as beam shelf, laminate, mesh cross beam, etc. on the beam to meet the cargo storage of different unit container equipment forms.

4) Generally, the goods are stored on the shelf after being packaged by unit container equipment such as pallets and storage cages. The load capacity of each unit is generally within 4000kg, and two units are usually placed on each layer (the span of unit shelves is generally within 4m, the depth is within 1.5m, the height of low and high level warehouses shelves is generally within 12m, and the height of ultra high level warehouses shelves is generally within 30m (such warehouses are basically automated warehouses, and the total height of shelves is composed of several sections of columns within 12m)

5) It can fully utilize the upper space of the warehouse, improve the space utilization rate of the warehouse, and is suitable for storing various goods.

6) Low cost, easy installation, easy to locate storage locations, with 100% of the goods being randomly selected. Handling machinery such as forklifts can reach any storage location for storage operations, making storage operations convenient and fast.

The use value of high level crossbeam shelves is mainly reflected in the combination of the width direction or special structure of the warehouse for special operations during operation, which makes it more convenient for customers to access goods and also improves universality. It is precisely because of the flexibility and versatility of the high-level crossbeam shelf that the economic benefits of the enterprise have been effectively improved to a certain extent. In this type of warehouse, most low and high level warehouses use forward moving battery forklifts, balance weight battery forklifts, and three-way forklifts for storage and retrieval operations. When the shelves are low, electric stackers can also be used, while high level warehouses use stackers for storage and retrieval operations. This type of shelf system has high space utilization rate, flexible and convenient access, supplemented by computer management or control, and can basically meet the requirements of modern logistics systems.

Hebei Woke HEGERLS high level crossbeam shelf is customized based on the length, width, and height of the pallet, and the direction of the pallet’s fork is more important. This direction determines the length of the shelf and is also one of the shelves with simple material items. It is also quite convenient to assemble and can be adjusted by 75MM. Strictly control the raw materials and accessories, and provide complete safety pins, sleeves, screw foot protectors and other accessories to prevent the crossbeam from falling off and ensure safety and reliability. When selecting and configuring high-level crossbeam shelves, it is necessary to comprehensively analyze the nature of inventory goods, unit loading and inventory, as well as factors such as warehouse structure and supporting loading and unloading equipment. In addition, the selection of shelves should consider factors such as item characteristics, accessibility, inventory, handling equipment, factory building structure, etc. The main factor is to make appropriate choices based on the functions of the storage area.

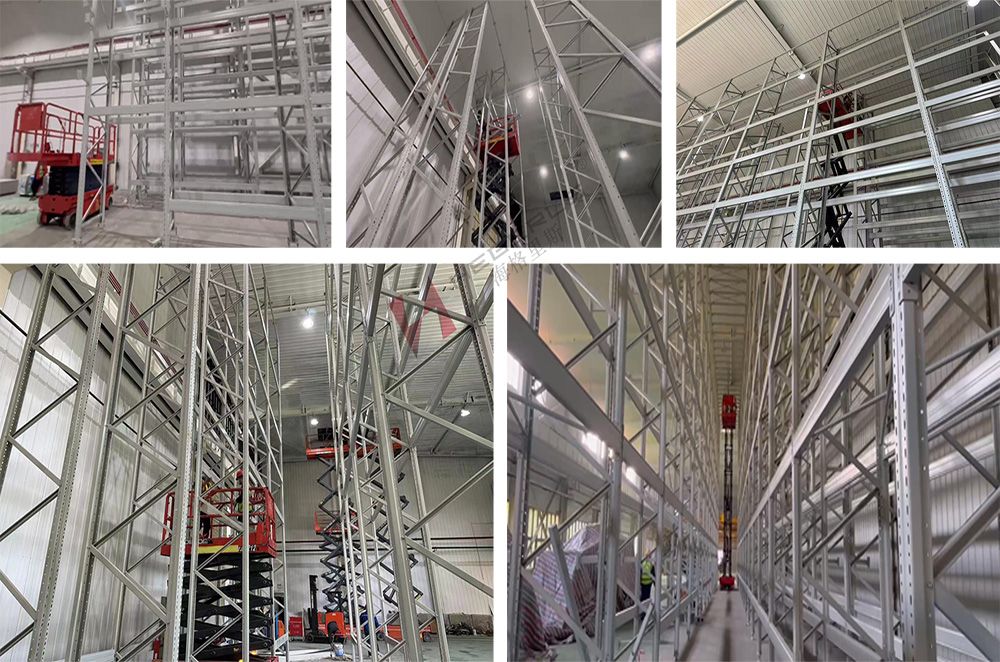

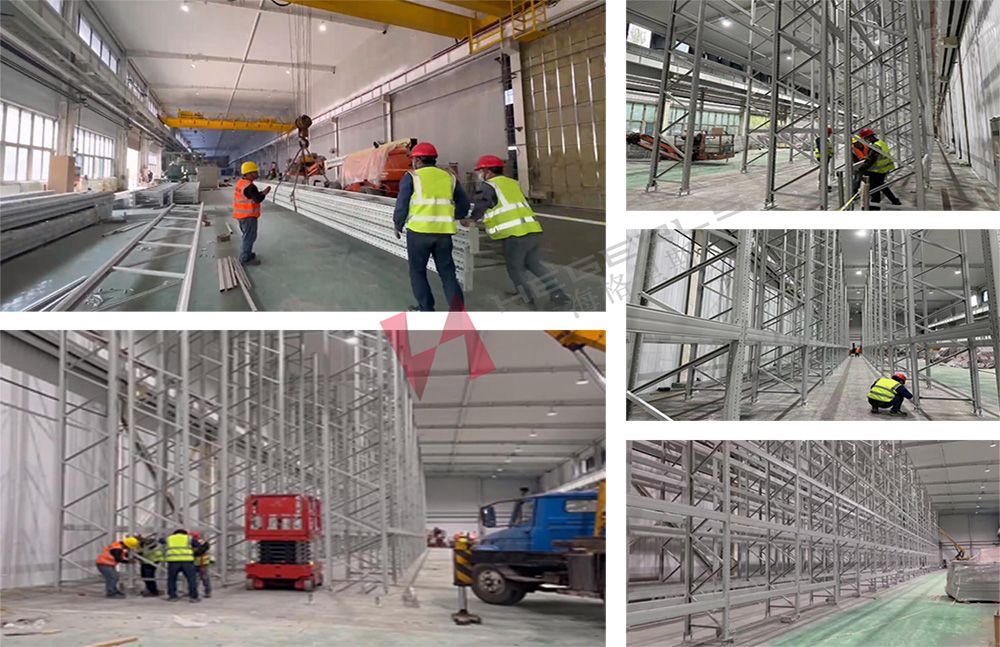

【Actual photos of the project】

Post time: May-10-2023