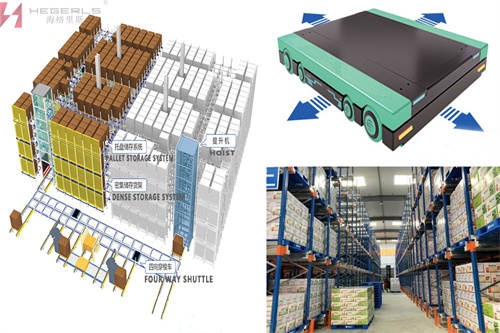

For most enterprises, they are familiar with the shelves of shuttle cars. Generally, shuttle cars can move back and forth on the rack track to carry goods. The other two directions cannot move due to restrictions. If there is a shuttle car that can move in all four directions, the overall storage efficiency will be improved several times, that is, the four-way shuttle car shelf. The four-way shuttle truck rack is an intelligent intensive storage rack that has emerged in recent years. By using the four-way shuttle truck to move goods on the horizontal and vertical tracks of the rack, one shuttle truck can complete the cargo handling work, greatly improving the work efficiency. Cooperating with the elevator, automatic warehouse management system (WMS) and warehouse dispatching system (WCS), the purpose of warehouse automatic storage can be realized and the automation of warehouse management can be improved. It is a new generation of intelligent storage rack system.

As the four-way shuttle shelf is put into use, most enterprises can find that the four-way shuttle system is more complex in control scheduling, order management, route optimization algorithm, etc. it is also very difficult to implement the project, so there are relatively few suppliers. However, hegerls is one of the few suppliers. Hegerls is a storage service manufacturing enterprise integrating R & D, design, production and sales. It is one of the domestic automatic storage and logistics equipment manufacturers. It has a complete production system with a variety of production equipment, production technology and perfect after-sales service, such as full-automatic shot blasting machine, numerical control stamping, cold and Hot Coil Slitting, general profile rolling mill, x-shelf rolling machine, welding, electrostatic powder automatic spraying and so on, It has laid a firm foundation for serving users in all walks of life and provided a guarantee! Hagerls focuses on the R & D, production and sales of storage racks, cable racks, attic racks, shuttle racks, heavy racks, through racks, cantilever racks, steel pallets, automated three-dimensional warehouses and non-standard station equipment. It also has independently developed WMS storage management system software.

Hegerls four-way shuttle rack

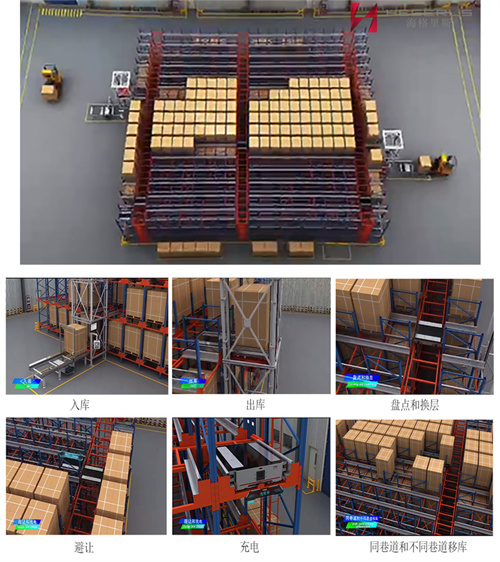

The four-way shuttle rack is an intelligent high-density storage rack type. It is an intelligent storage composed of shelves, shuttle cars and forklifts. It uses four-way shuttle cars to realize the horizontal and vertical track operation of the shelves. The horizontal movement and storage of goods are only completed by one shuttle car, which cooperates with the transfer of the elevator. With the cooperation of the automatic warehouse management system (WMS) and the warehouse dispatching system (WCS), when used with the elevator, it can effectively realize the horizontal and horizontal double track operation, so as to realize the storage Picking and sorting work.

Among them, the four-way vehicle is also known as the four-way shuttle vehicle. It can move horizontally and longitudinally along the predetermined track load to realize the storage of goods to the shelf. The equipment can realize automatic loading and unloading, automatic lane changing and layer changing, automatic climbing, and can also be transported and driven on the ground. It is the latest generation of intelligent transportation equipment integrating automatic stacking, automatic transportation, unmanned guidance and other functions. The four-way shuttle vehicle is highly flexible. It can change the working lane at will, and adjust the system capacity by increasing or decreasing the number of shuttle vehicles. If necessary, it can respond to the peak of the system and solve the bottleneck of entry and exit operations by establishing the dispatching mode of the operation fleet.

The four-way shuttle car system developed, produced and manufactured by hegerls is more flexible. At the same time, the lane can be changed at will and the operation can be stopped at any position to adjust the system capacity by increasing or decreasing the number of shuttle cars. In addition, the four-way shuttle car system is modular and standardized. All AGV cars can be replaced with each other, and any car can continue to perform the task of the problem car. The four-way shuttle car system can flexibly adjust the working lane of the shuttle car and “unbound” the lane and the hoist, so that the bottleneck problem of the multi-layer shuttle car on the hoist can be solved. In addition, the equipment can be configured completely according to the working flow, reducing the waste of equipment capacity. The cooperation between the shuttle car and the hoist is also more flexible and flexible. In the traditional multi-layer shuttle system, if the elevator breaks down, the whole tunnel operation will be affected, while the four-way shuttle system will not be affected. Meanwhile, compared with the traditional multi-layer shuttle shelf system, the four-way shuttle will have more advantages in safety and stability. It is suitable for low flow and high-density storage and also for high flow and high-density storage and picking, It can also better meet the needs of customers.

Unique characteristics and advantages of the shelves of hegerls four-way shuttle vehicle

▷ super high-rise shelf storage: because its four-way shuttle car can move in four directions, it greatly increases the flexibility to adapt to the site. When encountering some irregular sites, it can also operate flexibly, improving the overall space utilization rate of the warehouse and saving the storage area, which is about 5-6 times that of the ordinary warehouse. At present, the height of the world’s highest three-dimensional warehouse has reached 15-20m, and the storage capacity per unit area can reach 8t / m2. It is more convenient, intelligent, funny and cost-effective to access goods.

▷ four-way travel: it can travel in any direction along the longitudinal or transverse tracks on the cross track of the three-dimensional rack, and reach any cargo location in the warehouse through the instructions sent by the system, without the need of other external equipment. It is unnecessary to purchase any other handling devices and equipment in the automatic warehouse, which greatly reduces the handling cost.

▷ automatic leveling: the pallet is automatically leveled by the displacement sensor, and the wheels on both sides are driven at the same time to ensure that the intelligent four-way shuttle does not deflect and avoid the risk of goods overturning.

▷ automatic access: fast operation and processing speed, capable of real-time transmission with ERP, WMS and other systems to the enterprise’s material system.

▷ intelligent control: the whole vehicle has two control modes: fully automatic and semi-automatic. In the automatic mode, goods can enter and exit the warehouse without manual operation, which is convenient for counting and inventory, and the inventory range can be reasonably controlled, which greatly improves the efficiency of goods access and the space utilization of the warehouse.

▷ seamless connection: realize seamless connection in the process of production, warehouse and sorting.

▷ fault problem: when encountering obstacles or reaching the end of the operation, the four-way shuttle can make corresponding response and stop automatically to select its best operation route to continue the operation.

▷ strong anti-collision performance: the overall structure of the four-way shuttle rack adopts a brand-new design, which makes its anti-collision performance significantly enhanced. Because the four-way shuttle rack is inevitably bumped in the normal operation process, if the anti-collision performance of the equipment is not strong, it will easily lead to the damage of the machine body and affect the operation efficiency of the warehouse. However, the four-way shuttle rack has good anti-collision performance, This can be effectively avoided.

▷ storage system: the four-way shuttle cargo ship is composed of two parts: the four-way shuttle and the storage rack system. It has high stability and safety. If the hoist in the system fails, the four-way shuttle can continue to operate through other hoists or connecting equipment, so that the whole rack system can continue to operate, and the whole system is basically unaffected.

▷ efficiency advantage: the work station and the three-dimensional shelf are directly connected to each other, and there is no secondary handling link in the warehouse, which reduces the labor cost and cargo damage rate.

▷ strong expansibility: the running space is not limited, and the shelves can be expanded as required to meet the actual needs of customers.

▷ resource sharing: use the cloud platform for warehouse data analysis and data resource sharing.

▷ FIFO: goods are first in, first out, and can be freely selected;

▷ seismic resistance: the seismic safety performance is much higher than that of the drive in shelf;

▷ cost reduction: in terms of the overall cost of the system, compared with the traditional multi-layer shuttle car system, the cost of the traditional multi-layer shuttle car is closely related to the number of lanes. Under the condition of increasing the order volume and not increasing the inventory, each lane of these systems will increase the corresponding cost, while the four-way shuttle car system only needs to increase the number of shuttle cars, and the overall cost will be lower.

Four way shuttle shelf application scenario:

1) Intelligent factory workshop line side library;

2) Intelligent intensive storage finished product warehouse / semi-finished product warehouse / raw material warehouse;

3) Logistics distribution center warehouse;

4) Unmanned black light warehouse.

In fact, as a whole, from the current logistics and storage mode, in the medical, food, household appliances, automobile, tobacco and other industries, there are special-shaped warehouses (shape is different, and the warehouse in and out is different), floor warehouses (single floor warehouse, the warehouse is low), multi floor through warehouses (single floor warehouse is low, and the warehouse in and out may be on the first floor), flat warehouses (, ≤ 13.5m, the floor is too low, and it is not appropriate to use a stacker) The four-way shuttle car can meet the needs of different storage modes such as the vertical warehouse (≥ 18m, the use of stacker or insufficient efficiency).

Safety issues during shelf installation of hegerls four-way shuttle vehicle

The overall structure of the four-way shuttle rack is relatively large, and each part has many connection problems, which requires the operation of the installer. If it is not good enough, it is easy to appear. If the perpendicularity of the column is not enough, and the angle is not enough when installing the shelf, poor handling will have adverse effects on the overall shelf. In addition, the required safety accessories on the shelf are not installed or located correctly, which will weaken the protection. This role is not conducive to security. Improper operation of warehouse personnel when using shelves may also lead to the safety of shelves. For example, the excessive return of goods and the strong collision of the shelves may lead to the displacement or deformation of the shelves, thus affecting the safe use of the shelves.

With the progress of society, intelligent storage shelf products are constantly improving, and their functions and functions are becoming more and more important, which can promote the rapid development of the logistics industry. Therefore, we should not underestimate the progress of the intelligent storage industry and its value in society.

Post time: Aug-15-2022