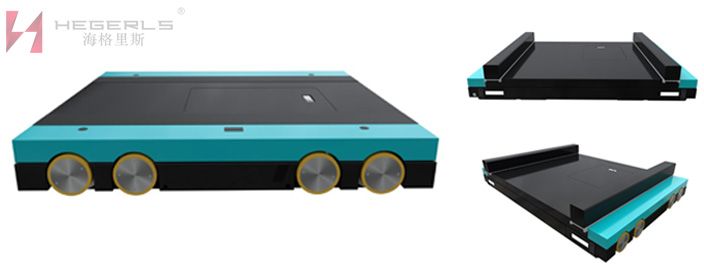

As an important transportation equipment for dense warehousing, the intelligent pallet type four-way shuttle car is an intelligent track guided automatic reversing and track changing transportation equipment. Under the control of the electric control system, it accurately locates each input and output station through digital technologies such as encoders, RFID, photoelectric sensors, and is equipped with an intelligent scheduling system. After receiving materials, it automatically shuttles back and forth for transportation. The pallet four-way car does not require human operation, Fast running speed and high level of intelligence, suitable for various logistics storage systems, can promote the rapid realization of flat automatic transportation of unit materials. Driven by intelligent scheduling systems, multi-layer and multi vehicle collaborative parallel operations are implemented to achieve precise and efficient operation modes, providing new logistics solutions for enterprise logistics storage systems.

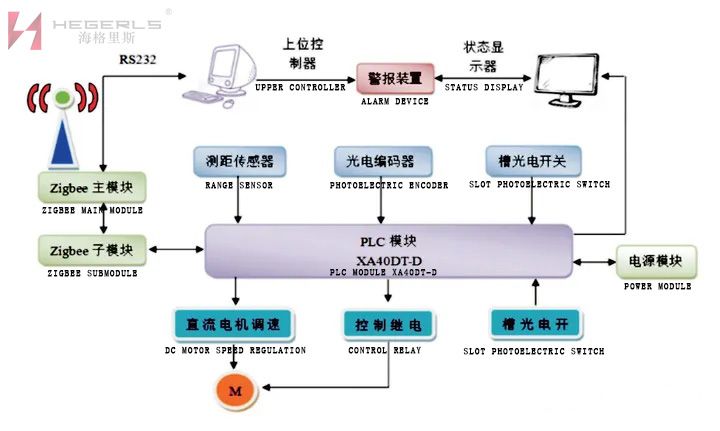

The main difficulties and key points in the implementation of the intelligent tray four-way shuttle vehicle storage system lie in hardware reliability, communication and positioning technology, scheduling system, etc. Specifically, in terms of hardware reliability, Hebei Woke HEGERLS mainly achieves product reliability from three aspects. Firstly, 16 sensors are configured on the vehicle body to ensure real-time monitoring of vehicle operation; Next, select the standard PLC from the Siemens s7-200 SMATER series to improve control stability. In addition, the HEGERLS pallet four-way shuttle adopts a modular design as a whole, which makes it more convenient and efficient to replace components when they fail. At the same time, it is also convenient for other small cars to provide support. All structural components are independently developed and produced by Hebei Woke, strictly controlling quality and accuracy.

In terms of communication and positioning technology, high-density goods and shelves generally interfere with the transmission of communication signals, thereby affecting the data exchange efficiency of the pallet four-way shuttle and its system, leading to inaccurate positioning and position loss. According to different actual situations, Hebei Woke has selected encoder positioning, laser positioning, barcode/two-dimensional code positioning, RFID positioning and other positioning methods to realize the seamless roaming of four-way shuttle vehicles in the warehouse, improve the anti-interference ability of the vehicle, enable it to automatically load balance, and thus eliminate single point of failure.

In terms of scheduling systems, only by implementing a multi vehicle scheduling system can the applicability of four-way shuttle vehicles be greatly improved. The HEGERLS four-way shuttle multi vehicle scheduling system includes four aspects: space traffic control, task allocation, equipment operation failure analysis, and path planning.

The overall mechanism design of the HEGERLS pallet four-way shuttle car independently developed and produced by Hebei Woke is also different from other manufacturers. The key mechanism design of the HEGERLS pallet four-way shuttle car is as follows:

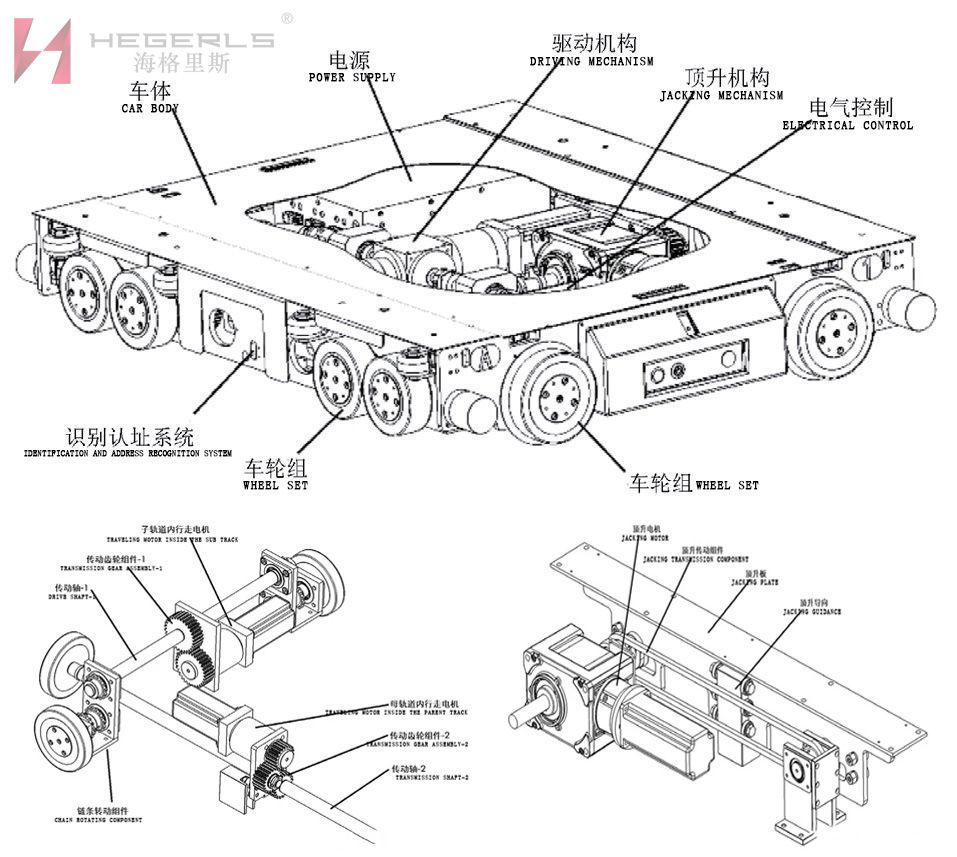

According to the task requirements, the four-way vehicle cooperates with the reciprocating elevator to complete the operation tasks in different layers and cargo lanes of the shelves through the running track. Under the control and scheduling of the warehouse monitoring system, the entire dense warehouse can achieve multi-layer and multi vehicle simultaneous operation. Each four-way vehicle can upload information such as location, speed, electricity, availability, faults, and working conditions to the information management system during operation; The four-way vehicle has functions such as bulk storage and retrieval, cargo movement, and pallet counting, enabling rapid material delivery and inventory management; It is internally equipped with obstacle avoidance function and fault alarm prompt function, which can provide safety protection and timely feedback of fault information. From the hardware system perspective, the four-way vehicle is mainly composed of components such as the frame, lifting mechanism, driving mechanism, wheel group, power supply, electrical control, etc.

1) Vehicle structure

The modular design technology is applied to the body structure of the four-way vehicle, which is formed by combining high-quality steel. The designed load capacity of the vehicle is 1500 kg or more, and the minimum safety factor is recommended to be 1.6. The material yield strength is 2.75 MPa; The four-way vehicle body structure has been optimized for the reliability of the entire vehicle and the lightweight of the structure.

2) Jacking mechanism

The four-way vehicle operation requires multiple top-down and reversing actions, and a mechanical mechanism or hydraulic top-down device should be designed. Considering the safety, reliability, and durability of the mechanical structure, it is recommended to have a lifting stroke of 40 mm and a lifting time of 3-5 seconds. The four-way vehicle completes one operation cycle by lifting and lowering the pallet and reversing the lifting of goods. To improve operation efficiency, it is necessary to ensure that the four-way vehicle quickly lowers and reverses during the operation process to shorten the operation cycle.

3) Drive mechanism and wheels

The four-way vehicle driving mechanism adopts a servo motor drive, planetary deceleration and commutator to promote rapid commutation in both directions. Under normal operating conditions, the no-load operating speed is 1.4 m/s~1.6 m/s, and the full load operating speed is 1.0 m/s~1.2 m/s; When running horizontally on the shelf level, the four-way vehicle adopts 4-wheel drive in the X direction and 8-wheel drive in the Z direction. The 8-wheel (combination of driving and driven wheels) transmission mode is selected to meet the system design requirements, ensuring the stability of the vehicle’s walking while reducing the complexity of the internal mechanical system. When a four-way car is in motion, its wheels are subject to long-term friction and require wear-resistant wheels. After performance testing, polyurethane wheels are selected for durability, reducing noise and ensuring operational stability.

The flexible multi-layer and multi vehicle operation mode of the Hagrid HEGERLS pallet four-way shuttle greatly improves the efficiency of inbound and outbound operations, solving the bottleneck problem of traditional three-dimensional warehouses where the stacker can only enter and exit in one lane. In recent years, based on the actual needs of domestic and foreign warehousing markets, Hebei Woke has developed pallet four-way shuttle cars with technological advantages such as novel appearance, complete functions, safety and reliability. In addition to domestic and foreign after-sales service systems, in the future, Hebei Woke will firmly grasp the strong momentum of intelligent warehousing development, always adhere to customer demand orientation, and continue to bring high intelligence and decision-making to customers Integrated intelligent warehousing overall solution.

Post time: May-19-2023