Intelligent three-dimensional warehouse is an important logistics node in modern logistics system. It is more and more widely used in logistics center. The intelligent three-dimensional warehouse is mainly composed of shelves, roadway Stacking Cranes (stackers), warehouse entry (exit) work platforms, dispatching control systems and management systems. The operation process of the intelligent three-dimensional warehouse is generally warehousing, handling in the warehouse, goods storage, picking up and goods out of the warehouse The whole work is carried out under the control of the computer system. The computer system is generally a three-level management and control system. The upper computer is connected to the LAN, and the lower computer is connected to the controller PLC to transmit data through wireless and wired methods. At the same time, the establishment of intelligent warehouse plays a significant role in improving the logistics efficiency of enterprises. Of course, the problem arises. Most enterprises or individuals may sometimes wonder how the intelligent warehouse operating system is used correctly, and what is the difference between it and ordinary warehouses? What are the key points in each process that deserve our attention? Follow the steps of hegerls storage shelf manufacturer, and explore the details of the intelligent warehouse operating system together!

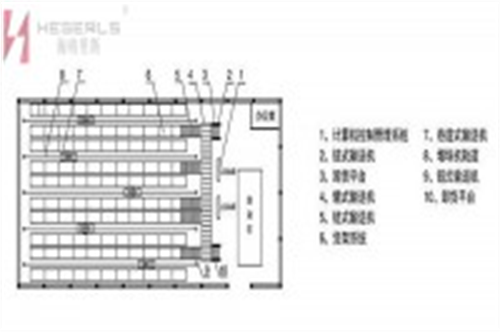

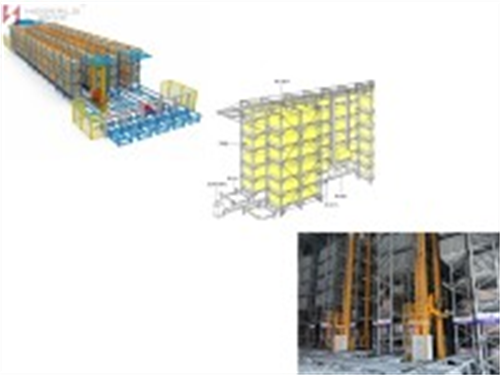

At the beginning, we have already mentioned that the main body of the intelligent warehouse is composed of shelves, roadway type Stacking Cranes, warehouse entry (exit) workbench and automatic transportation in (exit) and operation control system. Among them, the shelf is a building or structural body of steel structure or reinforced concrete structure, the shelf is a standard size cargo space, and the roadway stacking crane runs through the roadway between the shelves to complete the work of storage and pick-up; In terms of management, WCS system is used for control.

Here are the key points in the process of the intelligent warehouse operating system, as follows:

Warehousing process: the management system will respond to the warehousing request, and then the warehousing dialog box will pop up, allowing the user to fill in the name and quantity of the warehousing goods;

Order query: then the system queries the order quantity. When the order quantity is greater than the goods inventory quantity, the system will give an alarm prompt. Otherwise, the operating system will send a receipt operation Mo to the computer and print it into a receipt data sheet;

Warehousing scanning: the warehousing computer controls the barcode system to scan the goods;

Sorting and transportation: after scanning, the warehousing computer will again judge whether the scanned goods are consistent with the task. If so, the warehousing sorting and transportation will be carried out. If not, an alarm signal will be given.

Consolidation and consolidation: before small-size goods or parts are warehoused, consolidation and consolidation are generally required to meet the storage requirements and make full use of the storage space volume. Large-size goods can be warehoused directly or put into pallets according to the situation.

(Hercules hegerls storage shelf manufacturer should also explain the key points of the details of consolidation and consolidation: Generally speaking, fixed consolidation and consolidation are adopted, that is, multiple goods or parts of the same kind are placed in one pallet or container; in some cases, in order to further increase the storage capacity, the consolidation mode of loose parts can be adopted, that is, random varieties and quantities are assembled into containers. In this mode, the In the database, information such as the batch code, the batch code, and the arrival batch code of goods and parts are set to link the quantity and type of goods in each plate with their storage location, so as to facilitate the reverse plate and consolidation at the time of delivery.)

Barcode scanning input: Generally speaking, the barcode of goods contains four types of information, namely, pallet number, article number, batch number and quantity. (Note: the barcode is read by the scanner, interpreted by the decoder, and then transmitted to the computer through the serial port interface)

Issue process: when the management system responds to the issue request, the issue dialog box will pop up, allowing the user to fill in the name and quantity of the issued goods;

Inventory quantity query: when the operating system queries the inventory quantity, if the issue quantity is greater than the inventory quantity of goods, an alarm will be given; otherwise, the system will send the issue task document to the issue computer and print the issue document;

Outbound instruction: the outbound computer sends an outbound instruction to the stacker machine, which is shipped from the shelf and transported to the outbound platform. The outbound computer controls the barcode system to scan the goods;

Sorting and repacking: after scanning, the warehouse computer will judge whether the scanned goods are consistent with the task. If they are consistent, the warehouse sorting and repacking will be performed. If not, an alarm signal will be given.

For the operation of ASRS, a key point to be mentioned by Hercules hegerls storage shelf manufacturer is the operation of stacker. There are also eight points that the enterprise operators should pay attention to, as follows:

1) Operating instructions: before operating the stacker, the operator shall carefully read the ASRS operation manual of the three-dimensional warehouse, or the operation can only be carried out after correct guidance;

2) Air compressor: before the stacker (upper computer) is started, the air compressor must be opened until the pressure is maintained, and then the stacker can be operated for warehousing, otherwise the pallet and line body will be damaged by the fork;

3) Access to goods: manual access to ASRS goods in the three-dimensional warehouse shall be prohibited;

4) Induction equipment: during inbound and outbound operations, it is forbidden for trainees to cover the induction equipment of the inbound, outbound or sorter jacking translation machine with their hands;

5) Status mark: in fact, there are three status marks on the stacker, namely, manual status, semi-automatic status and automatic status. The manual status and semi-automatic status are only used by commissioning or maintenance personnel. If they are used without authorization, they will bear the consequences; During training, it is confirmed to be in automatic status;

6) Emergency stop button: the stacker is in automatic state, and the access operation is directly carried out by the stacker. In case of emergency or failure, pressing the emergency stop button on the upper computer interface or the whole line stop button on the electric control cabinet of the conveying line also has the effect of emergency stop;

7) Personnel safety: during inbound and outbound operations, it is forbidden for trainees to approach or enter the three-dimensional warehouse and track roadway, and do not get too close around the three-dimensional warehouse, keeping a distance of at least 0.5m;

8) Adjustment and maintenance: the whole line needs to be adjusted every six months. Of course, non professional personnel are not allowed to dismantle and overhaul at will.

Of course, we also mentioned that what is the difference between ASRS and ordinary warehouses?

In fact, it is not difficult to see that the biggest difference between the intelligent automated three-dimensional warehouse ASRS and the ordinary warehouse lies in the automation and intelligence of the warehouse in and warehouse out:

Ordinary warehouse means that goods are put on the ground or on ordinary shelves (usually less than 7 meters) and are manually put in and out of the warehouse by forklift; The intelligent automated three-dimensional warehouse ASRS is that the goods are placed on the high shelf (usually less than 22 meters), and under the control of the software, the lifting equipment automatically enters and exits the warehouse.

Of course, the key points that the intelligent automated three-dimensional library ASRS is better than ordinary warehouses lie in the following aspects:

Seamless connection: it can be connected with the upstream automatic production system and the downstream distribution system to improve the breadth and depth of enterprise supply chain automation.

Informatization: information identification technology and supporting software realize the informatization management inside the warehouse, which can grasp the inventory dynamics in real time and realize rapid scheduling.

Unmanned: the seamless connection of various handling machinery can realize the unmanned operation of the whole warehouse, so as to reduce the labor cost and avoid the hidden danger of personnel safety and the risk of goods damage.

High speed: the delivery speed of each lane exceeds 50 Torr / h, which is much higher than that of forklift truck, so as to ensure the delivery speed of warehouse.

Intensive: the storage height can reach more than 20m, the roadway and cargo space are almost the same width, and the high-level intensive storage mode greatly improves the land utilization rate.

Post time: Jun-09-2022