Intelligent automated three-dimensional warehouse is a new concept in today’s logistics warehousing, and it is also a storage mode with high technical level at present. It mainly uses three-dimensional warehouse equipment to realize high-level rationalization, storage automation and simple operation of the warehouse, which has high economic and social benefits. At present, the emergence of various new technologies has promoted the development of intelligent automated three-dimensional warehouse towards a more intelligent and flexible direction. So if you want to put this automated three-dimensional warehouse into use, how to build it?

About hagerls warehousing

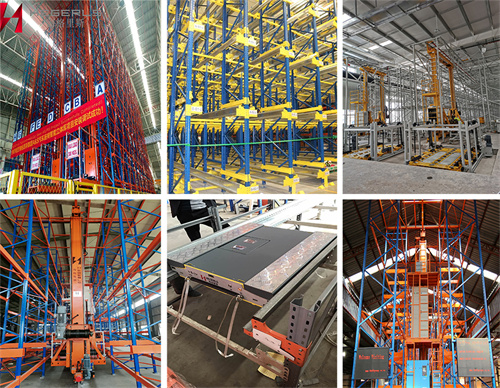

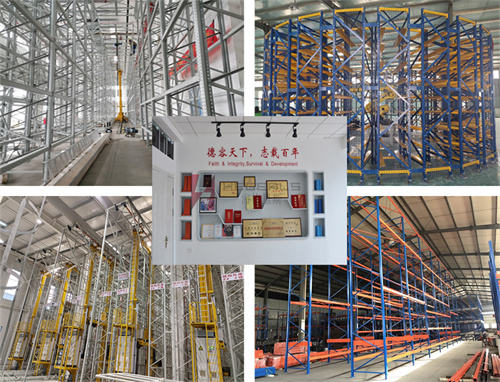

Hagerls is the main independent brand of Hebei Walker metal products Co., Ltd. and began to intervene in the sales and installation of warehousing and logistics equipment in 1998. After more than 20 years of development, it has become a high-tech enterprise integrating intelligent logistics solutions and warehousing systems, integrating warehousing and logistics project scheme design, equipment and facilities production, sales, integration, installation, commissioning, warehouse management personnel training, after-sales service, etc. Headquartered in Shijiazhuang, the production base is located in Xingtai, Bangkok, Thailand, Kunshan, Jiangsu and Shenyang sales branches. It has a production and R & D base of 60000 square meters, 48 world advanced production lines, and more than 300 people in R & D, production, sales, installation and after-sales, including nearly 60 people with senior technician and senior engineer titles. In recent years, the company has strengthened the research and development of automatic storage equipment. Two automatic storage equipment, intelligent shuttle car and intelligent plate warehouse stacker, have won national patents, and basically completed the transformation from exporting primary products to exporting complete sets of automatic equipment and undertaking to complete storage projects.

Hergels warehousing has been operating in strict accordance with ISO9001 quality system, ISO14001 environmental system and other health and safety management systems, and has always pursued an international management and control mode to ensure the high quality and stability of Hergels products. Haggis has always attached great importance to product R & D and innovation, and has a number of national patents in storage shelves, stackers, conveyors, shuttle cars, warehouse control and management. Especially in recent years, the intelligent automated three-dimensional library produced by Hergels has been favored by major enterprises at home and abroad. Now let haggis herrls warehouse take you to the standard analysis. How is ASRS intelligent automated three-dimensional warehouse built?

1、 Basic facilities of automated three-dimensional warehouse

The basic facilities of automated three-dimensional warehouse include civil engineering and public engineering facilities, mechanical facilities and electrical facilities.

1) Civil engineering and utilities

Civil engineering and public engineering facilities mainly include plant, lighting system, ventilation and heating system, power system, water supply and drainage facilities, fire protection system, lightning protection and grounding facilities, environmental protection facilities, etc.

2) Mechanical facilities

Mechanical facilities can be said to be an important part of the automated three-dimensional warehouse. They include high-rise shelves, roadway Stacking Cranes, warehousing and transportation machinery, etc. among them, the structure of high-rise shelves, roadway Stacking Cranes, warehousing and transportation machinery is as follows:

▷ high shelf

High rise shelves are necessary facilities in automated three-dimensional warehouses. Using high-rise shelves to store goods can make full use of warehouse space and improve space utilization. At the same time, unit goods format shelves, gravity shelves and rotating shelves are generally used. Each two rows of high-rise shelves will form a group, and a lane is set in the middle of each two groups of shelves, so that the lane stacking crane and forklift equipment and facilities can run normally in operation, and each row of shelves is divided into several columns and horizontal rows to form a shelf or storage space, which is mainly used to store pallets or containers.

▷ roadway stacking crane

The roadway stacking crane can be said to be an important equipment in the automated three-dimensional warehouse, also known as the roadway stacking machine. Its operation must be accurate positioning and address recognition, otherwise it will take the wrong goods, damage the goods and shelves, and seriously damage the stacking machine itself. The position control of the stacker adopts the absolute address recognition method, and the laser rangefinder is used to determine the current position of the stacker by measuring the distance from the stacker to the base point and comparing the data stored in PLC in advance. It is high cost, but also high reliability. It is mainly composed of frame, operating mechanism, lifting mechanism, fork telescopic mechanism and electrical control equipment. It is mainly used to work and operate in the roadway of high-rise shelves, store the goods at the entrance of the roadway into the goods grid, or take out the goods in the goods grid and transport them to the entrance of the roadway. In addition, the roadway stacker can also move horizontally along the track between shelves, and the loading platform can also move vertically up and down along the stacker support. At the same time, the fork of the loading platform can also move to the left and right directions of the platform with the help of telescopic machinery, so as to realize the three-dimensional movement of the stored and stored goods. Moreover, the rated load of roadway stacker is generally dozens of kilograms to several tons, and most enterprises use 0.5T more; Its walking speed is generally 4~120m/min, while the lifting speed is generally 3~30m/min.

▷ warehousing and transportation machinery

There are mainly two modes of in and out of the warehouse transportation and handling machinery: unpowered and powered. Among them, unpowered in and out of the warehouse transportation and handling machinery is also divided into spoke type and roller type; The power in and out transportation and handling machinery is divided into chain conveyor, belt conveyor, spoke conveyor, etc. The equipment and facilities for transportation and handling in and out of the warehouse also include automatic guided vehicles, pallets, forklifts, loading and unloading robots, such as containers or pallet equipment and facilities. Generally speaking, automated three-dimensional warehouses often use containers or pallets as carriers. It is necessary to know that containers can be used to place all kinds of goods with irregular shapes and scattered goods, which are reliable, safe and not easy to scatter; The cost of using pallets is low, but only goods with regular shape or outer packaging can be placed, and the stacking height on the pallets cannot be too large. In addition, pallets have high requirements for the detection system of the stacker. If they cannot be detected correctly, goods may collide. Another example is the equipment and facilities in and out of the storage buffer station. The buffer station is mainly to coordinate the production rhythm and ensure the timely and accurate supply of materials. It can play a regulating role in the event of production equipment failure, processing process changes, transportation congestion, etc. The processing of access buffer station information is closely related to the production environment, including rigid assembly line buffer station, processing and manufacturing buffer station and buffer material warehouse.

3) Electrical and electronic facilities

The electrical and electronic facilities in the automated three-dimensional warehouse mainly include detection devices, control devices, information recognition devices, large screen display equipment, image monitoring equipment, communication equipment, computer management equipment, etc.

2、 Information management system of automated three-dimensional warehouse

The information management system of automated three-dimensional warehouse includes system maintenance, demand management, order management, storage management, unqualified goods management, inventory management and other subsystems, as follows:

▷ system maintenance

System maintenance refers to the initialization of the whole system, which is generally used to set various codes and processing methods, mainly including consolidation mode, warehousing mode, batch mode and date, database and initialization of location code.

▷ demand management subsystem

The demand management subsystem mainly determines the required quantity and time of materials according to the production plan, inventory, goods list, date, sales status and other information.

▷ order management subsystem

The order management subsystem is mainly used to make orders, enter contracts, manage purchase schedules, count contracts, and provide managers with basic archives such as the reputation, supply capacity and production technology information of suppliers.

▷ storage management subsystem

The storage management subsystem mainly provides various functions in storage management, including storage location management, warehousing management, outbound management, inventory management and other subsystems.

▷ nonconforming goods management subsystem

The nonconforming goods management subsystem mainly refers to the management of various nonconforming goods after parts arrive at the factory or goods arrive at the company. According to the nonconforming goods returned from warehousing acceptance, production and sales, a claim form and a compensation form are generated, and then the nonconforming goods are deducted from the inventory.

▷ inventory management subsystem

The inventory management subsystem is mainly used to complete inventory statistics, inventory status analysis, ABC classification management, etc.

3、 Operation management of automated warehouse

The operation management of automated three-dimensional warehouse is mainly responsible for reasonably arranging the incoming and outgoing operations, and completing the task of transporting materials between the production line and the flat warehouse (or other systems). Warehouse in and warehouse out are the main contents of three-dimensional warehouse operations. Taking manufacturing enterprises as an example, the basic operation links are: parts warehouse out, parts warehouse in, finished goods warehouse out, finished goods warehouse in, as follows:

▷ parts delivery

In order to meet the real-time needs of production line processing, the required parts are sent to the designated buffer station. The delivery application comes from the processing buffer station or the station buffer station. The delivery application puts forward requirements for material variety, model, quantity and supply time limit. After receiving the application, the three-dimensional warehouse will query the location (usually more than one) of the required materials in combination with the current inventory situation. According to the principle of location management fee, determine the location number of stock out, and immediately form the parts stock out task list, such as the location number of stock out, the minimum time limit of supply, the stock out number, etc.

▷ parts warehousing

When the parts are sent to the storage desk of the three-dimensional warehouse, the barcode recognizer reads the information, puts forward the storage application, sends it to the designated location, and forms the parts storage task list.

▷ finished products warehousing

When the processed finished products arrive at the storage desk of the three-dimensional warehouse, the barcode reader reads the information of the finished products (number, quantity, etc.) and applies for storage. Combined with the current location situation, the three-dimensional warehouse will find a suitable empty location for the finished product according to the location management principles, and form a warehouse return task list at the same time.

▷ finished goods delivery

When processing an issue request, you can issue by specifying the location or the required issue quantity of a material. At the same time, you can raise the priority of the task according to the urgency of the task. After formulating the delivery plan and notifying the stereoscopic warehouse to implement it, the stereoscopic warehouse shall determine the delivery time, quantity, quality, type, etc. of finished products according to the delivery plan outside the factory, and determine the location number of each finished product to be delivered.

Automated three-dimensional warehouse is a complex automation system, which is composed of many subsystems. In automated three-dimensional warehouse, in order to complete the specified tasks, a lot of information exchange should be carried out between systems and equipment. For example, the communication between the host and the monitoring system, the monitoring system and the control system in the automated three-dimensional warehouse, and the communication between the warehouse management computer and other information systems through the computer network. The media of information transmission include cables, far-infrared light, optical fibers and electromagnetic waves.

Post time: Jul-28-2022